Used high frequency tube mills on the impact of welded tube blank defects on the quality of welded tube (7)

- Sort:Information

- Auth:

- Source:

- Release time:2021-12-04 11:30

- Pvs:

【概要描述】If the used high frequency tube mills refers to the chemical composition and mechanical properties of welded tube blanks that require certain inspection methods to be known as invisible defects; then, those defects that can be seen only by vision are called tube blanks. Overt defect.

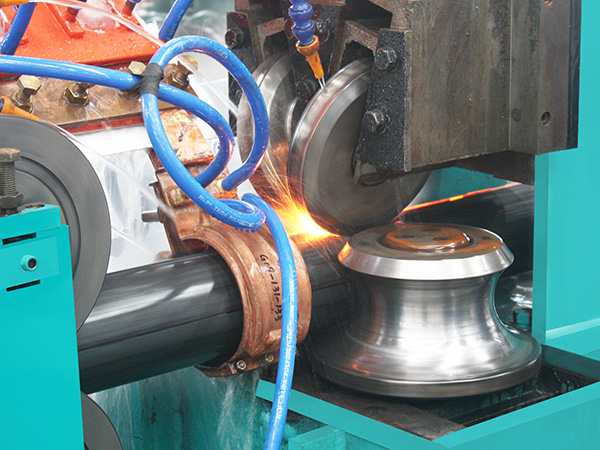

Used high frequency tube mills on the impact of welded tube blank defects on the quality of welded tube (7)

【概要描述】If the used high frequency tube mills refers to the chemical composition and mechanical properties of welded tube blanks that require certain inspection methods to be known as invisible defects; then, those defects that can be seen only by vision are called tube blanks. Overt defect.

- Sort:Information

- Auth:

- Source:

- Release time:2021-12-04 11:30

- Pvs:

If the used high frequency tube mills refers to the chemical composition and mechanical properties of welded tube blanks that require certain inspection methods to be known as invisible defects; then, those defects that can be seen only by vision are called tube blanks. Overt defect.

The dominant defects of the welded tube blank of the used high frequency tube mills generally include cracked edges, broken edges, sawtooth, pitting, scratches, roll marks, dark spots, edge burrs, sickle bends, wrinkles, waves, edge warping, and points. Layers, warped skins, pinholes, sticky rolls, soft spots, rust, oxide layers, towers, loose rolls, etc. Let me introduce you to the causes of cracked edges and the impact of cracked edge billets on welded pipes.

Horizontal wrinkles

Horizontal wrinkles refer to the horizontal fold lines on the surface of the tube blank. To measure whether wrinkles can be eliminated, it depends on the size of the R angle at the bottom of the wrinkles. When R<0.5mm, it is considered that the wrinkles are difficult to completely eliminate during the production process of welded pipes.

The ideal situation for wrinkles to be eliminated is: there is a look but not the touch. Transverse wrinkles mostly occur on thin-walled tube blanks.

Causes of horizontal wrinkles:

(1) The billet is too soft. For example, a tube blank with a thickness of 0.8 mm or less and a width of 100 mm or more, when the hardness is lower than 100 HV, is prone to transverse wrinkles.

(2) The cold-rolled tube billet has not undergone finishing and straightening, and the surface is easy to yield.

(3) There is too much material stored in the cage storage bin, and they are squeezed too tightly, resulting in "dead folds" at the folds of the tube blank.

The influence of transverse wrinkles on the quality of welded pipe:

(1) It hinders the surface quality of the welded pipe, and the thicker pipe wall can make it look and feel, but it will increase the load of the equipment.

(2) The horizontal wrinkles that cannot be eliminated will form irregular "0" and "C" rings on thin-walled pipes or pipes with a wall thickness of less than 0.7mm, making the post-treatment of the pipe surface difficult. Many, or will increase the processing cost. Therefore, in the production of welded pipes, it is necessary to avoid the use of tube blanks that cannot be eliminated with transverse wrinkles.

(3) The welding process is unstable, each wrinkle is equivalent to a "miniature bulge", and the weld strength is not guaranteed.

Regarding the defects of the welded tube blank of the used high frequency tube mills (7) the causes of transverse wrinkles and the influence of transverse wrinkles on the quality of welded tubes, I hope it can help you.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province