Used high frequency tube mills, three important links in the quality control of the production process (2)

- Sort:Information

- Auth:

- Source:

- Release time:2021-12-26 11:30

- Pvs:

【概要描述】In the production process of making steel pipes on the used high frequency tube mills production line, three links of raw materials, welding technology and roll adjustment should be focused on control.

Used high frequency tube mills, three important links in the quality control of the production process (2)

【概要描述】In the production process of making steel pipes on the used high frequency tube mills production line, three links of raw materials, welding technology and roll adjustment should be focused on control.

- Sort:Information

- Auth:

- Source:

- Release time:2021-12-26 11:30

- Pvs:

In the production process of making steel pipes on the used high frequency tube mills production line, three links of raw materials, welding technology and roll adjustment should be focused on control.

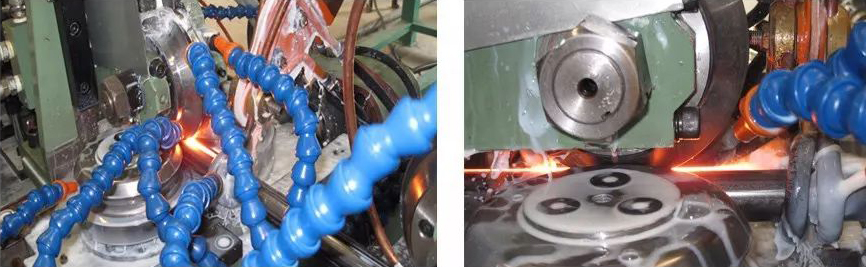

Secondly, the used high frequency tube mills must control the high-frequency welding

In the process of high-frequency welding of steel pipes with used high frequency tube mills, the control of welding process and process parameters, the placement of induction coils and resistors, etc. have a great influence on the welding quality of steel pipe welds.

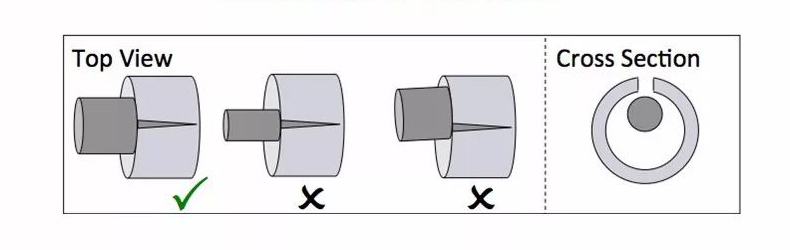

1. Control of steel pipe weld gap

After the steel strip is formed by a second-hand high-frequency tube mill and the guide roller is oriented, a round steel tube blank with an open gap is formed. The squeeze amount of the squeeze roller is adjusted to control the weld gap between 1 and 3 mm. Keep the weld ends flush. If the weld gap is controlled too large, the weld will be poorly welded and cause unfusion or cracking; if the weld gap is controlled too small, excessive heat will cause the weld to burn, molten metal splashes, and affect the welding quality of the weld.

2. Adjustment of the position of the high-frequency induction coil

The induction ring should be placed on the same center line as the steel pipe. The distance between the front end of the induction ring and the center line of the squeeze roller should be as close as possible depending on the specifications of the steel pipe without burning the squeeze roller. If the induction coil is far away from the squeeze roller, the effective heating time is longer and the heat-affected zone is wide, so that the strength of the steel pipe weld is reduced or the weld is not penetrated; on the contrary, the induction coil is easy to burn the squeeze roller.

3. Regulation of the position of the resistor

Resistor is one or a group of special magnetic rods for welded pipes. The cross-sectional area of the resistor should usually not be less than 70% of the cross-sectional area of the inner diameter of the steel pipe. Its function is to make the induction coil, the edge of the pipe blank weld and the magnetic rod form an electromagnetic induction loop. The proximity effect is produced, and the eddy current heat is concentrated near the edge of the weld of the tube blank, so that the edge of the tube blank is heated to the welding temperature. The impedance device should be placed in the heating section of the V-shaped zone, and the front end should be at the center of the squeeze roller so that its center line is consistent with the center line of the tube. If the impedance device is not placed properly, it will affect the welding speed and welding quality of the welded pipe, and cause the steel pipe to crack.

4. High-frequency welding process parameters-control of input heat

When the high-frequency input heat is insufficient and the welding speed is too fast, the edge of the heated pipe body cannot reach the welding temperature, and the steel still maintains its solid structure and cannot be welded, forming cracks that are not fused or welded; When the high-frequency input heat is too large and the welding speed is too slow, the edge of the heated pipe body will exceed the welding temperature, which is prone to overheating or even burning, causing the weld to break down, causing metal splash and forming shrinkage holes.

We can control the amount of high-frequency input heat by adjusting the high-frequency welding current (voltage) or adjusting the welding speed, so that the weld seam of the steel pipe needs to be penetrated and not penetrated, and a steel pipe with excellent welding quality can be obtained.

The three important links of raw material, welding and roll adjustment in the production process of welded steel pipes are carried out on the used high-frequency tube mills. If strict control is implemented, the quality of welded pipes will be effectively improved.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province