Used high frequency tube mills, three important links in the quality control of the production process (1)

- Sort:Information

- Auth:

- Source:

- Release time:2021-12-23 11:30

- Pvs:

【概要描述】In the production process of making steel pipes on the used high frequency tube mills production line, three links of raw materials, welding technology and roll adjustment should be focused on control.

Used high frequency tube mills, three important links in the quality control of the production process (1)

【概要描述】In the production process of making steel pipes on the used high frequency tube mills production line, three links of raw materials, welding technology and roll adjustment should be focused on control.

- Sort:Information

- Auth:

- Source:

- Release time:2021-12-23 11:30

- Pvs:

In the production process of making steel pipes on the used high frequency tube mills production line, three links of raw materials, welding technology and roll adjustment should be focused on control.

The used high frequency tube mills must first control the raw materials

The results of causal analysis of scrap steel pipes show that the main factors affecting the quality of raw materials are the instability of the mechanical properties of the steel strip, the surface defects of the steel strip and the large deviation of geometric dimensions.

1. The influence of the mechanical properties of the steel strip on the quality of the steel pipe

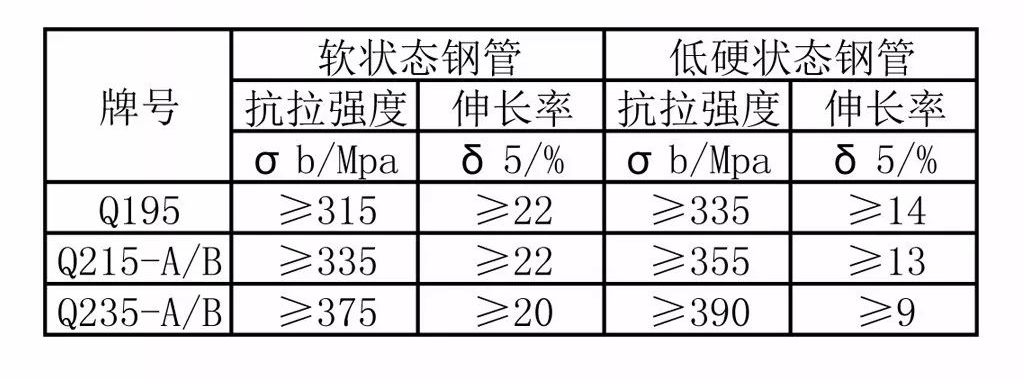

The commonly used steel grades for welded steel pipes are carbon structural steels. The main grades are Q195, Q215, and Q235, and their mechanical properties are specified in the following table.

Mechanical properties of three kinds of carbon structural steel pipes

The high yield point and tensile strength of the steel strip will cause difficulty in forming the steel strip, especially when the pipe wall is thick, the material has a large resilience, the steel pipe has a large deformation stress during welding, and the weld is prone to cracks. When the tensile strength of the steel strip exceeds 635MPa and the elongation is less than 10%, the weld seam of the steel strip is prone to cracking during the welding process. When the tensile strength is lower than 300Mpa, the surface of the steel strip is prone to wrinkles due to the soft material during the forming process, especially when welding steel pipes with a diameter of more than 60mm, obvious and regular ring-shaped wrinkles appear on the surface of the steel pipe. When the wrinkles are severe, the entire batch of steel pipes will be scrapped. It can be seen that the mechanical properties of materials have a great influence on the quality of steel pipes, and the quality of steel pipes should be effectively controlled from the aspect of material strength.

2. The influence of steel strip surface defects on the quality of steel pipes

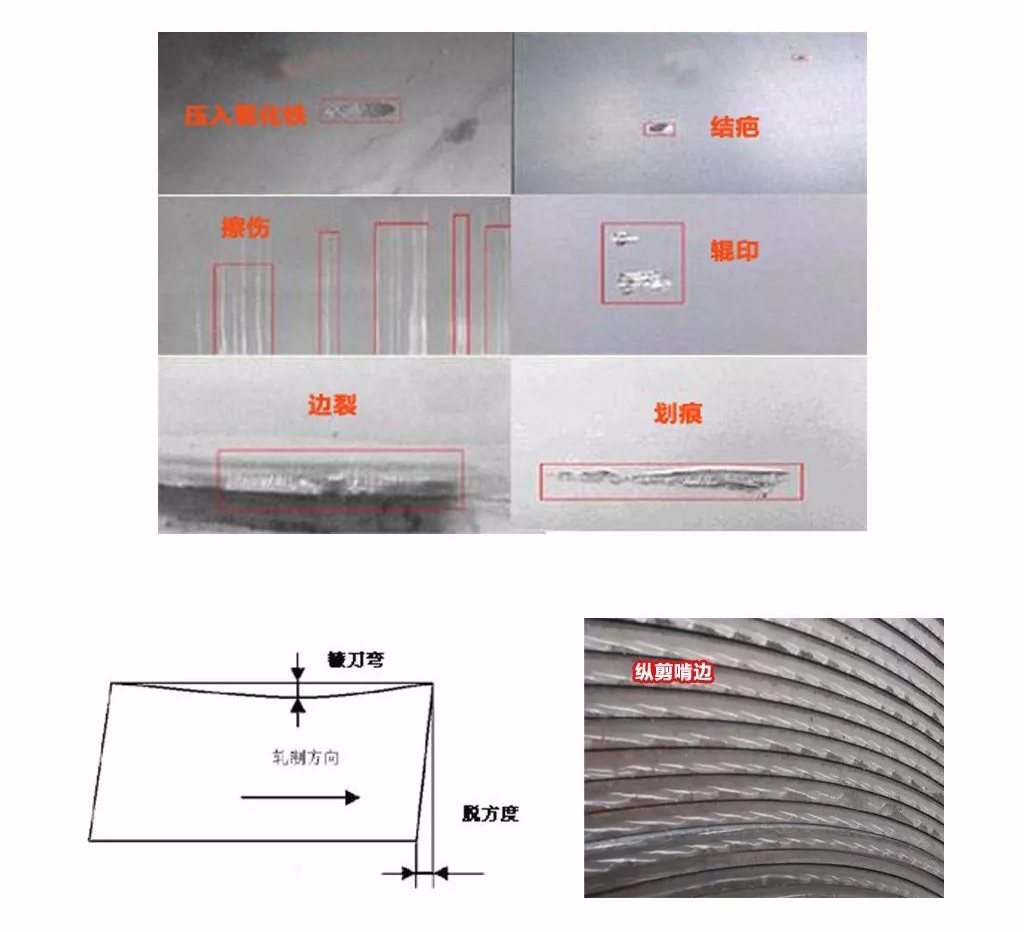

Common surface defects of steel strip include sickle bend, wave shape, slitting gnawing, etc. The sickle bend and wave shape generally appear in the rolling process of cold-rolled steel strip and are caused by improper reduction control. In the forming process of the steel pipe made by the used high frequency tube mills, the sickle bend and the wave shape will cause the strip steel to deviate or turn over, which will easily cause lap welding of the steel pipe weld and affect the quality of the steel pipe. The gnawing edge of the steel belt (that is, the phenomenon that the edge of the steel belt is jagged and uneven) generally appears on the slitting belt. The reason is that the blade of the slitting machine is blunt or not sharp. Due to the gnawing of the steel strip, local meat shortages often occur, which makes the steel strip prone to cracks and cracks during welding, which affect the stability of the weld quality.

3. The influence of the geometrical size of the steel strip on the quality of the steel pipe

When the width of the steel strip is less than the allowable deviation, the squeezing force when welding the steel pipe is reduced, so that the welding seam of the steel pipe is not firmly welded, cracks or open pipes; when the width of the steel strip is greater than the allowable deviation, the welding of the steel pipe The squeezing force increases, and welding defects such as sharp beaks, lap welding or burrs appear at the welding seam of the steel pipe. Therefore, the fluctuation of the width of the steel strip not only affects the accuracy of the outer diameter of the steel pipe, but also seriously affects the surface quality of the steel pipe. For steel pipes that require the same section wall thickness difference not to exceed the specified value, both the steel pipe with a high degree of wall thickness uniformity, and the fluctuation of the thickness of the steel strip, the allowable value of the thickness difference of the same coil will be transferred to the wall thickness difference of the finished steel pipe. , So that the thickness of a large number of steel pipes exceeds the allowable deviation and is rejected. The fluctuation of the thickness not only affects the thickness accuracy of the finished steel pipe, but at the same time, due to the different thickness of the steel strip, the extrusion force and welding temperature of the steel pipe are unstable when the steel pipe is welded, which causes the quality of the weld seam to be unstable when the steel pipe is welded.

In addition, due to material defects such as interlayers, impurities, and blisters in the steel, it is also an important factor affecting the quality of the steel pipe. Therefore, before welding the steel strip with the used high frequency tube mills, check the surface quality and geometric dimensions of each coil of steel strip. If the quality of the steel strip does not meet the standard requirements, do not carry out production to avoid unnecessary losses.

The three important links of raw material, welding and roll adjustment in the production process of welded steel pipes are carried out on the used high frequency tube mills. If strict control is implemented, the quality of welded pipes will be effectively improved.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province