Used high frequency tube mills, the development of welding pipe forming technology (4)

- Sort:Information

- Auth:

- Source:

- Release time:2022-01-18 11:30

- Pvs:

【概要描述】Used high frequency tube mills to produce welded pipe forming technology is developed in three stages according to time period and forming method: Roll Forming,Caga Forming, and Flexible Forming Excellent.

Used high frequency tube mills, the development of welding pipe forming technology (4)

【概要描述】Used high frequency tube mills to produce welded pipe forming technology is developed in three stages according to time period and forming method: Roll Forming,Caga Forming, and Flexible Forming Excellent.

- Sort:Information

- Auth:

- Source:

- Release time:2022-01-18 11:30

- Pvs:

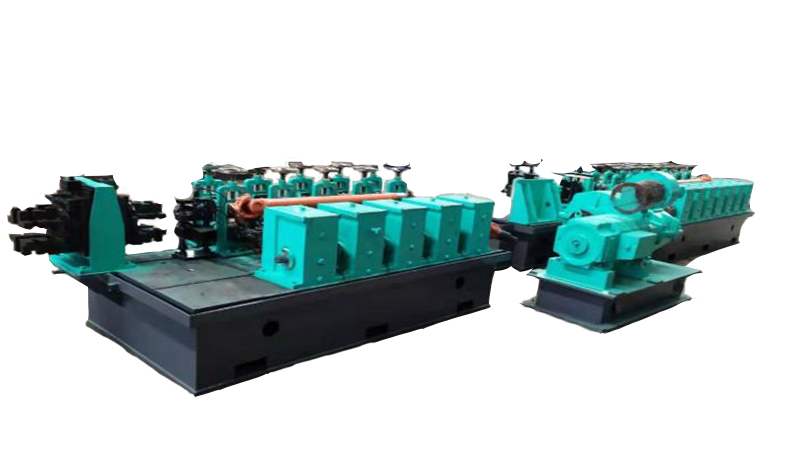

Used high frequency tube mills to produce welded pipe forming technology is developed in three stages according to time period and forming method: Roll Forming,Caga Forming, and Flexible Forming Excellent.

Used high frequency tube mills welded pipe forming technology includes two parts: rough forming and fine forming. It is the core of high-frequency welded pipe production technology. If the forming quality of the steel strip in the rough forming and finishing stages is not good or the forming is not in place, it is difficult to produce Produce high-quality welded pipes. Therefore, the forming technology determines the output, variety, quality, raw material and roll consumption of the high-frequency welded pipe, which is a matter of great concern to the design and manufacturing department and the user department of the welded pipe equipment.

Let's start to talk about the characteristics of these three molding technologies.

Problems in roll forming:

3. The inherent quality of welded pipe products has declined.

Due to the uneven deformation of the outer row of rollers and inner rollers to the steel strip, the degree of local work hardening of the welded pipe material is increased, the residual stress is large and the distribution is uneven. Although the external dimensions can meet the product requirements, the material performance has undergone major changes compared to the steel strip base material. The inherent toughness, elongation, and stress corrosion resistance of the welded pipe have been compromised. High-grade line pipes and casings requiring corrosion-resistant media have a great impact.

4. Insufficient thrust and unstable welding speed.

In the forming process of high-frequency longitudinal welded pipes, the thrust provided by the roller drive is completely dependent on the steel belt to overcome the deformation resistance and maintain the stability of the welding speed. Due to the reduction of the horizontal frame, the thrust to overcome the deformation is reduced. Especially when the thickness of the steel belt is large and the material strength is high, the phenomenon of insufficient thrust is prone to occur, and the forming speed of the steel belt fluctuates. In order to make up for the lack of thrust and stabilize the welding speed, it is also required to increase the number of precision forming machines.

5. The equipment has poor rigidity, thick-walled and high-strength welded pipe production.

Compared with the earlier ones, many inner rolls are used in the current row roll forming machine, but the increase in the number of inner rolls will also cause some problems. First of all, due to space constraints, the size of the inner roll is small, and the small size of the inner roll is likely to cause local high stress areas and indentations on the inner surface of the steel strip. At the same time, due to space constraints, the support device of the inner roller can only adopt a cantilever structure, and the strength and rigidity of the inner roller are insufficient. This problem is a common problem in row-roll forming technology, which limits the production of high-strength and thick-walled welded pipes by this type of forming machine.

Secondly, in order to adapt to the production of welded pipes of different sizes, used high frequency tube mills must install an adjustment mechanism to adjust these inner rollers, or use many inner rollers to correspond to the welded pipe size. Adopting the adjustment mechanism will inevitably occupy space, and further weaken the strength and rigidity of the inner roller. Therefore, in most cases, according to the size of the welded pipe, only the inner rolls of different sizes are used in different stages, which increases the workload of roll change and roll cost.

Our company has many brands and wide resources, there is always one suitable for you. You only need to tell us your pipe manufacturing needs, our company will provide you with used welded pipe equipments that really suits your needs, welcome new and old customers to come to consult and order.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province