Used high frequency tube mills, the development of welding pipe forming technology (3)

- Sort:Information

- Auth:

- Source:

- Release time:2022-01-15 11:30

- Pvs:

【概要描述】Used high frequency tube mills to produce welded pipe forming technology is developed in three stages according to time period and forming method: Roll Forming,Caga Forming, and Flexible Forming Excellent.

Used high frequency tube mills, the development of welding pipe forming technology (3)

【概要描述】Used high frequency tube mills to produce welded pipe forming technology is developed in three stages according to time period and forming method: Roll Forming,Caga Forming, and Flexible Forming Excellent.

- Sort:Information

- Auth:

- Source:

- Release time:2022-01-15 11:30

- Pvs:

Used high frequency tube mills to produce welded pipe forming technology is developed in three stages according to time period and forming method: Roll Forming,Caga Forming, and Flexible Forming Excellent.

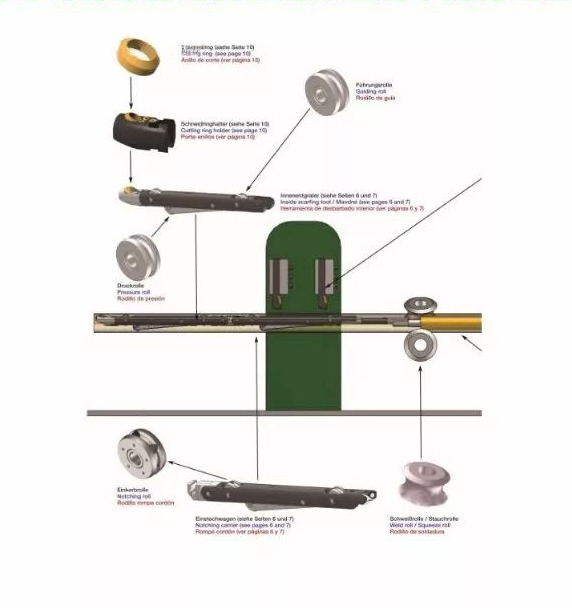

Used high frequency tube mills welded pipe forming technology includes two parts: rough forming and fine forming. It is the core of high-frequency welded pipe production technology. If the forming quality of the steel strip in the rough forming and finishing stages is not good or the forming is not in place, it is difficult to produce Produce high-quality welded pipes. Therefore, the forming technology determines the output, variety, quality, raw material and roll consumption of the high-frequency welded pipe, which is a matter of great concern to the design and manufacturing department and the user department of the welded pipe equipment.

Let's start to talk about the characteristics of these three molding technologies.

Problems in roll forming:

1. The weakening of rough forming deformation is the root cause of defects in welded pipes.

Due to the one-sided pursuit of roll sharing in order to reduce the number of rolls and the number of roll changes, the horizontal roll stand for roll forming is reduced, and the amount of deformation originally deformed by the horizontal roll stand is more transferred to the roll section and fine forming on board. The roller row section is composed of many outer row rollers and some inner rollers. The outer row rollers are mainly deformed by applying pressure to the outer surface of the steel belt, and the inner roller deforms the inner surface of the steel belt.

Due to the requirement of commonality, the outer row rolls and the inner rolls do not have a hole pattern, plus space constraints, the size of the rolls is small, and the adjustment of the inner rolls is difficult. The outer row and inner rollers locally apply pressure to the steel belt, which makes the steel belt deformed unevenly, and a large area on the edge becomes the deformation dead zone; the outer row and inner rollers are small in size and poor in rigidity. For steel with large thickness and high material strength The degree of deformation of the belt is limited, and it is difficult to achieve the purpose of full plastic deformation. The dead zone of deformation is more serious, and the steel belt is easy to rebound. These are the root causes of many defects and hidden dangers of welded pipe caused by the roll forming technology.

2. Insufficient deformation of rough forming, increasing the number of precision forming machines and sizing machines.

In the production of used high frequency tube mills, the deformed state of the edge of the steel strip has a great influence on the welding quality. The curvature of the edge of the best steel belt open tube is very close to that of the welded tube, and this deformation needs to be completed in the rough forming stage. However, due to the reduction of horizontal roller racks, the roll forming technology is difficult to achieve in the rough forming stage. The deformation has to be placed on the roll row section and the fine forming machine. However, in the roll row section, it is also very difficult due to the structure of the equipment. It is difficult to guarantee, and the result is that the roundness of the welded pipe after welding is poor.

In order to improve the roundness of welded pipes, it is required to increase the number of finishing machines and sizing machines. Therefore, the number of finishing machines and sizing machines produced by the three major companies in the world are both 3 and 4 frames. Although the number of precision forming racks has increased, after rough forming, the V-shaped angle at the edge of the steel belt opening tube cannot be effectively controlled. When the thicker welded pipe enters the hole of the finishing machine, there is a big difference with the angle of the guide disc (fin). Under the pressure of the finishing machine, the side of the steel belt opening tube will produce severe local plasticity. Deformation causes abnormal thickening of the edges of the steel strip. This not only damages the formation of large internal burrs after milling, makes it difficult to scrape the internal burrs, reduces the life of the internal burr knife, and also increases the material consumption. The deformation of the horizontal roller frame is reduced. In addition, the outer and inner rollers in the roller forming frame have no holes, which makes it very weak to control the deformed shape of the steel strip. At the same time, because the steel belt itself is different to avoid unevenness in plate shape, size and material, it is impossible to maintain absolute symmetry in mechanical properties. Therefore, the steel belt is prone to torsion instability during the rough forming process, and once torsion occurs Dynamic (unstable) phenomenon, once the twisting phenomenon occurs, it is difficult to be corrected in the fine forming, and in severe cases, normal forming and welding cannot be carried out.

Our company has many brands and wide resources, there is always one suitable for you. You only need to tell us your pipe manufacturing needs, our company will provide you with used welded pipe equipments that really suits your needs, welcome new and old customers to come to consult and order.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province