Used high frequency tube mills, common problems of high-frequency welding (6)——high-frequency ignition

- Sort:Information

- Auth:

- Source:

- Release time:2021-11-11 11:30

- Pvs:

【概要描述】High-frequency sparking is very common in the high-frequency welding of used high-frequency tube mills, which seriously affects the quality of high-frequency welding, and may also cause the downtime of the welding unit.

Used high frequency tube mills, common problems of high-frequency welding (6)——high-frequency ignition

【概要描述】High-frequency sparking is very common in the high-frequency welding of used high-frequency tube mills, which seriously affects the quality of high-frequency welding, and may also cause the downtime of the welding unit.

- Sort:Information

- Auth:

- Source:

- Release time:2021-11-11 11:30

- Pvs:

High-frequency sparking is very common in the high-frequency welding of used high-frequency tube mills, which seriously affects the quality of high-frequency welding, and may also cause the downtime of the welding unit.

Common reasons for high-frequency sparking in used high-frequency tube mills:

1.Due to the metal oxide impurities contained in the emulsion, when the roll is cooled, part of the metal oxide causes the insulating parts to be connected to electricity.

2.There are burrs on the edge of the trimmed board. The board edge burrs are easy to overlap before welding the V angle, causing ignition.

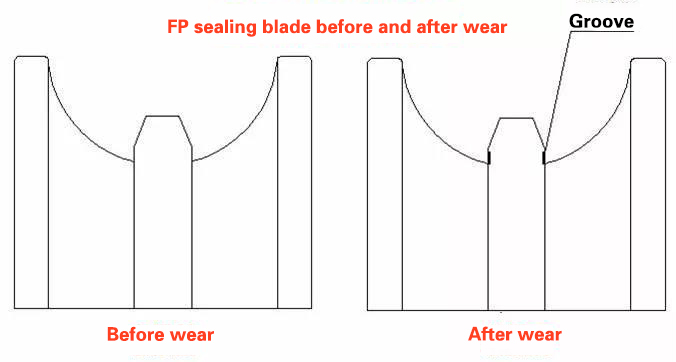

3. In the long-term use of the FP roll, the sealing blade is severely worn, and grooves are formed at the bottom of the sealing blade. Because of the steps appearing in the groove and the unweared part, when the edge of the plate passes, under the action of shearing, a lot of the edge of the plate is produced. The generated burrs overlap in advance before welding the V angle, causing ignition (the picture below).

4.Dirt generated by long-term operation accumulates near the induction coil, which is likely to be connected to electricity and cause ignition.

5. The components of the induction device are not installed properly, there is a virtual connection or the insulation parts are damaged in long-term operation.

There are many factors to judge the quality of welded pipe forming and welding of the used high-frequency tube mills, such as the shape of the strip edge, the amount of misalignment, the shape of the internal and external burrs, the amount of welding extrusion, the welding temperature, the resistance, the cooling water, and the high-frequency welding gold Phase test. only by fully understanding the various influencing factors of forming welding, can we quickly and accurately judge the welding status.

Part of the content of this site comes from the Internet. This site only provides information storage. The copyright belongs to the original author. It does not bear the relevant legal responsibility and does not represent the views and positions of this site. Please contact and delete it if there is any infringement.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province