Used ERW tube mills, how to adjust the squeeze roll "Two top rolls and two side vertical rolls"

- Sort:Information

- Auth:

- Source:

- Release time:2022-01-31 11:30

- Pvs:

【概要描述】When the used ERW tube mills is used to make welded pipes, it is necessary to rely on the control of the squeeze roller to judge the quality of the welded pipe to be qualified. Therefore, the control of the squeeze roller is very important. There are many ways to control the squeeze roll. "Two top rolls and two side vertical rolls" is one of the squeeze roll methods.

Used ERW tube mills, how to adjust the squeeze roll "Two top rolls and two side vertical rolls"

【概要描述】When the used ERW tube mills is used to make welded pipes, it is necessary to rely on the control of the squeeze roller to judge the quality of the welded pipe to be qualified. Therefore, the control of the squeeze roller is very important. There are many ways to control the squeeze roll. "Two top rolls and two side vertical rolls" is one of the squeeze roll methods.

- Sort:Information

- Auth:

- Source:

- Release time:2022-01-31 11:30

- Pvs:

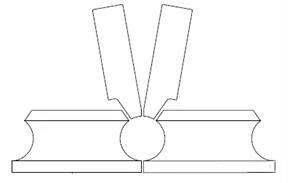

When the used ERW tube mills is used to make welded pipes, it is necessary to rely on the control of the squeeze roller to judge the quality of the welded pipe to be qualified. Therefore, the control of the squeeze roller is very important. There are many ways to control the squeeze roll. "Two top rolls and two side vertical rolls" is one of the squeeze roll methods.

The "two top rollers and two side vertical rollers" four-roller extrusion method can be said to be the first choice for used ERW tube mills at present for units above 114. The two top rollers and the two side vertical rollers can be adjusted independently, and the two top rollers are effective. Fit the edges of the steel strip to form a good extrusion force and effectively control the edges of the steel strip. For large-wall steel pipes, this method can fully reflect its advantages. The two-side vertical rolls cover less than 150 degrees, which effectively reduces the diameter of the squeeze rolls, shortens the length of the Vee, and improves the welding efficiency. It is an ideal form of welding and extrusion.

The disadvantage is that due to mechanical structural considerations and restrictions, the diameter of the upper two top rollers cannot be effectively reduced (usually equivalent to the diameter of the side vertical roller), and the bonding line with the steel strip is too long. High-frequency current is inevitable.

The above is the method of adjusting the squeeze roll "two top rolls and two side vertical rolls" of the used ERW tube mills, and the method ⑤ "two top rolls, two side vertical rolls and one bottom roll" will be introduced in the next issue. If you need it, you can pay attention to the method in the next issue. At the same time, if you need second-hand welded pipe equipment, please contact us. You only need to inform us of your pipe-making needs, and our company will provide you with used welded pipe equipments that really suits your needs.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province