Used ERW tube mills, formation and removal of burrs in welded pipes

- Sort:Information

- Auth:

- Source:

- Release time:2022-01-01 11:30

- Pvs:

【概要描述】When the used ERW tube mills is used to manufacture welded pipes, internal burrs will occur. Once the internal burrs are not removed in time, the manufacturing quality of the welded pipes will be affected. Therefore, we must clearly understand the formation and removal of burrs in the welded pipe of the used ERW tube mills.

Used ERW tube mills, formation and removal of burrs in welded pipes

【概要描述】When the used ERW tube mills is used to manufacture welded pipes, internal burrs will occur. Once the internal burrs are not removed in time, the manufacturing quality of the welded pipes will be affected. Therefore, we must clearly understand the formation and removal of burrs in the welded pipe of the used ERW tube mills.

- Sort:Information

- Auth:

- Source:

- Release time:2022-01-01 11:30

- Pvs:

When the used ERW tube mills is used to manufacture welded pipes, internal burrs will occur. Once the internal burrs are not removed in time, the manufacturing quality of the welded pipes will be affected. Therefore, we must clearly understand the formation and removal of burrs in the welded pipe of the used ERW tube mills.

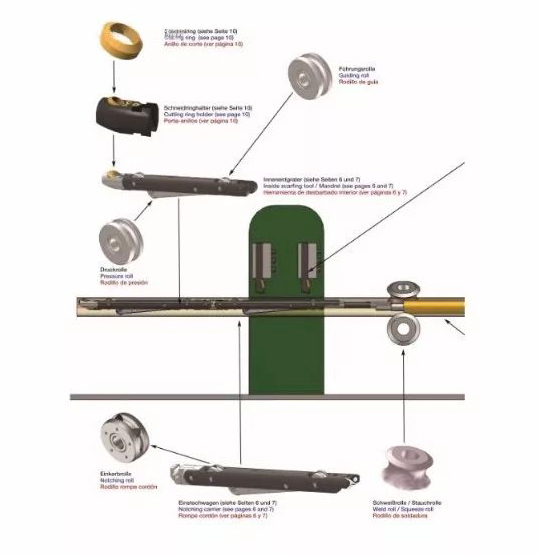

The internal burr removal of the used ERW tube mills is a necessary process for the production of high-quality, high-value-added straight seam resistance welded pipes. Welded pipes for oil, natural gas, chemical industry, coal water slurry, and precision high-strength structures (such as oil cylinders and cylinder pipes) ), plastic-lined steel-plastic composite pipes are required to remove internal burrs, but the removal process of internal burrs is a complicated process. Many factors in the actual production process will affect the quality of internal burr removal. In order to obtain an ERW welded pipe with high internal burr removal quality, it is necessary to analyze the common problems in the internal burr removal process and propose solutions to the main problems. So as to ensure the accuracy of internal burr removal and the stability during the removal process.

Formation and removal of internal burrs

Used ERW tube mills to produce ERW welded pipe. The edges of the tube blank after forming the ERW welded pipe are quickly heated to the molten and semi-melted state under the proximity effect of the high-frequency current, and the partially molten metal is squeezed out when entering the squeeze roll , Burrs are formed on the inner and outer surfaces of the welded pipe.

The metal melt entering the inner wall of the ERW welded pipe forms the inner burr of the welded pipe weld; the burr that is squeezed out of the outer weld is called the outer burr. Because the internal burr and removal equipment is in the pipe, the removal is relatively difficult, which has become one of the major technical problems in the production of ERW welded pipes.

Part of the content of this site comes from the Internet. This site only provides information storage. The copyright belongs to the original author. It does not bear the relevant legal responsibility and does not represent the views and positions of this site. Please contact and delete it if there is any infringement.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province