Used ERW tube mills, common method for removing burrs in welded pipe

- Sort:Information

- Auth:

- Source:

- Release time:2022-01-04 11:30

- Pvs:

【概要描述】When the used ERW tube mills is used to manufacture welded pipes, internal burrs will occur. Once the internal burrs are not removed in time, the manufacturing quality of the welded pipes will be affected. Therefore, we must clearly understand the common methods of removing burrs in welded pipes of used ERW tube mills.

Used ERW tube mills, common method for removing burrs in welded pipe

【概要描述】When the used ERW tube mills is used to manufacture welded pipes, internal burrs will occur. Once the internal burrs are not removed in time, the manufacturing quality of the welded pipes will be affected. Therefore, we must clearly understand the common methods of removing burrs in welded pipes of used ERW tube mills.

- Sort:Information

- Auth:

- Source:

- Release time:2022-01-04 11:30

- Pvs:

When the used ERW tube mills is used to manufacture welded pipes, internal burrs will occur. Once the internal burrs are not removed in time, the manufacturing quality of the welded pipes will be affected. Therefore, we must clearly understand the common methods of removing burrs in welded pipes of used ERW tube mills.

The internal burr removal of the used ERW tube mills is a necessary process for the production of high-quality, high-value-added straight seam resistance welded pipes. Welded pipes for oil, natural gas, chemical, coal water slurry, and precision high-strength structures (such as oil cylinders and cylinder pipes) ), plastic-lined steel-plastic composite pipes are required to remove internal burrs, but the removal process of internal burrs is a complicated process. Many factors in the actual production process will affect the quality of internal burr removal. In order to obtain an ERW welded pipe with high internal burr removal quality, it is necessary to analyze the common problems in the internal burr removal process and propose solutions to the main problems. So as to ensure the accuracy of internal burr removal and the stability during the removal process.

There are many methods for removing internal burrs. The more commonly used methods are roll pressing and online tool scraping. In addition, there are some grinding methods and oxidation methods used in special situations. However, these methods have greater limitations and have been gradually eliminated.

Rolling method is to use a pressure roller extending into the welded pipe to flatten the inner burr in the red hot state. In fact, the inner burr has not been removed, and it is pressed against the inner wall of the welded pipe, causing heavy layers and possibly The molten metal is pressed into the weld again to form weld inclusions, which leads to welding defects and stress concentration in the weld, which affects the mechanical properties and service life of the welded pipe. In addition, the internal appearance quality of the welded pipe is relatively poor.

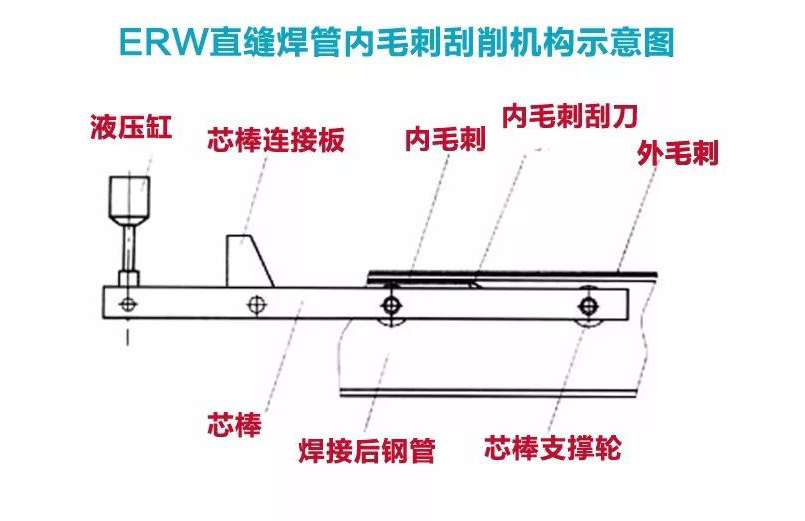

The online tool internal burr scraping method is based on the production specifications of the used ERW tube mills grinder. A fixed frame is installed in front of or behind the closed-hole frame, and the tool frame is penetrated into the burr in the welded pipe behind the squeeze roller through a cantilever mandrel. Adjust the cutter head to the position corresponding to the inner welding seam and the height close to the inner wall of the pipe. During the advancement of the welded pipe, the cutter head scrapes off the inner burr in the red hot state. According to the shape of the cutter head, there are two types of online tool scraping methods: ordinary cutter head and ring cutter head. This article mainly analyzes and discusses the common problems existing in the process of internal burr scraping of ordinary cutter head. The burr scraping mechanism in the ordinary cutter head is shown in the figure below.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province