Two forming processes for producing square and rectangular tubes by directly forming to square pipe mill

- Sort:Information

- Auth:

- Source:

- Release time:2022-08-24 11:30

- Pvs:

【概要描述】The square and rectangular pipe produced by the directly forming to square pipe mill is one of the varieties with the largest output in cold-formed steel, which is widely used in many industrial fields.

Two forming processes for producing square and rectangular tubes by directly forming to square pipe mill

【概要描述】The square and rectangular pipe produced by the directly forming to square pipe mill is one of the varieties with the largest output in cold-formed steel, which is widely used in many industrial fields.

- Sort:Information

- Auth:

- Source:

- Release time:2022-08-24 11:30

- Pvs:

The square and rectangular pipe produced by the directly forming to square pipe mill is one of the varieties with the largest output in cold-formed steel, which is widely used in many industrial fields.

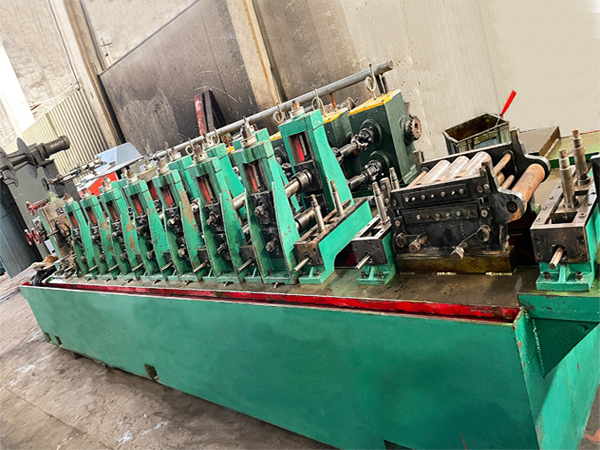

The forming process is divided into two types: direct forming and round-to-square. The direct forming process has been widely promoted and applied in our country, and the technological level of the process and equipment has been continuously developed. It has gone through several stages of technology introduction, digestion and absorption, and technological innovation. It has realized the development and transformation from relying entirely on imports in the initial stage to exporting in large quantities at present. This article introduces the forming process, key technology and new technology development trend of the square and rectangular tube produced by the directly forming to square pipe mill.

1. Square rectangular tube has a wide range of applications

The square rectangular tube produced by the directly forming to square pipe mill is a very versatile closed-end steel. Compared with the round tube of the same cross-sectional area, it has the advantages of high strength, large bending section modulus, easy assembly, stability, and beauty. It is widely used in construction machinery, vehicles, subway, shipbuilding and other industries. Especially in the construction industry, large-size square and rectangular pipes have become the main load-bearing structural components in steel structures.

Square and rectangular tubes are usually produced by cold-bending forming, that is, continuous roll forming. Because of the high productivity of the cold-formed forming method, uninterrupted production can be realized on the welded pipe production line, with high yield rate and low head loss, and it is widely used in mass production.

Many cold-formed steel production enterprises in China regard square rectangular pipes as their main product types. At present, the annual output of square rectangular pipes accounts for 97% of the total output. Products are used in construction, machinery, highways, bridges, ships, containers and other industries.

2. Forming process of square rectangular tube

The square and rectangular tubes produced by the directly forming to square pipe mill can be divided into direct forming, which is commonly known as "square to square (direct into square)" and "round to square (first round tube and then into square rectangular tube). "Two. With regard to the characteristics of these two processes, General Pian gives a comparison. The production companies also adopt different processes according to equipment conditions.

Comparing round to square and direct square

There are many books about the design methods of welding round tubes and square rectangular tubes. Here we mainly compare the methods commonly used in continuous roll forming.

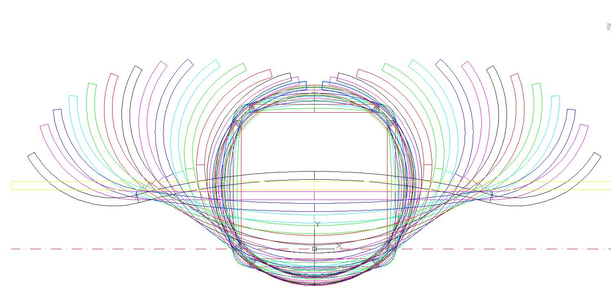

(1) "Round to square" process

After the strip steel is formed and welded into a round tube with the directly forming to square pipe mill, it is then shaped into a rectangular tube by a setting machine. Using the "round-to-square" process, the round pipe forming equipment can be used to first form a welded round pipe, and then change the round pipe into a square rectangular pipe in the sizing part. For the original round tube welding production line, the investment is small and easy to realize. The process is relatively straightforward and easy to control.

To 1. Rolling process drawing of forming a round tube first and then changing a square tube (using the method of unchanging the center of gravity and descending the hill)

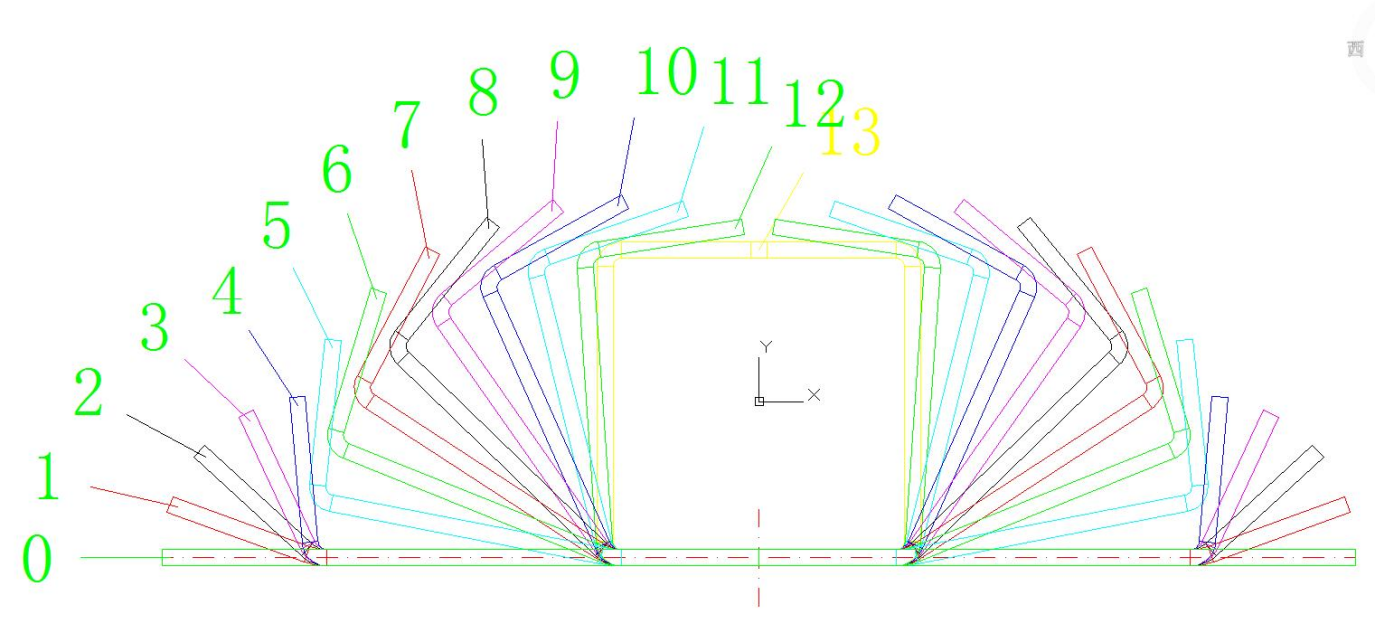

(2) "Directly forming a party" process

The process of directly bending the strip steel into a square and rectangular tube blank, and then welding and shaping.

Process drawing of roll flower directly forming square tube (downhill method is not used)

The above are the two forming processes of the rectangular tube produced by the directly forming to square pipe mill, and I hope to have some assistance to you. Our company has many brands and resources, and there is always one that suits you. You only need to inform us of your pipe-making needs, and our company will provide you with used welded pipe mills that truly suits your needs. Welcome new and old customers to consult and order.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province