The solution to the broken line of the thin-walled pipe surface of the used welded pipe equipment

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-12 11:30

- Pvs:

【概要描述】The fold line of the pipe surface when the used welded pipe equipment is making pipes refers to the thin and shallow dents on the surface of the formed pipe blank and in the circumferential direction, and the thicker and deeper ones are called "bamboo joints", which mostly occur in thin-walled and ultra-thin-walled pipes. On; the fold line can sometimes be seen but not touched, and some can be seen and touched, with a slight touch. A common feature is the presence of a surrounding tube blank.

The solution to the broken line of the thin-walled pipe surface of the used welded pipe equipment

【概要描述】The fold line of the pipe surface when the used welded pipe equipment is making pipes refers to the thin and shallow dents on the surface of the formed pipe blank and in the circumferential direction, and the thicker and deeper ones are called "bamboo joints", which mostly occur in thin-walled and ultra-thin-walled pipes. On; the fold line can sometimes be seen but not touched, and some can be seen and touched, with a slight touch. A common feature is the presence of a surrounding tube blank.

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-12 11:30

- Pvs:

The fold line of the pipe surface when the used welded pipe equipment is making pipes refers to the thin and shallow dents on the surface of the formed pipe blank and in the circumferential direction, and the thicker and deeper ones are called "bamboo joints", which mostly occur in thin-walled and ultra-thin-walled pipes. On the fold line can sometimes be seen but not touched, and some can be seen and touched, with a slight touch. A common feature is the presence of a surrounding tube blank.

The fundamental reason is that the tube blank is soft and wrinkled. The following measures can be taken to adjust in the used welded pipe equipment:

(1) Abandon the material storage, let the unit drag the tube blank away, and then stop the machine to pick up the tape. Although the efficiency is lower, the quality can be guaranteed.

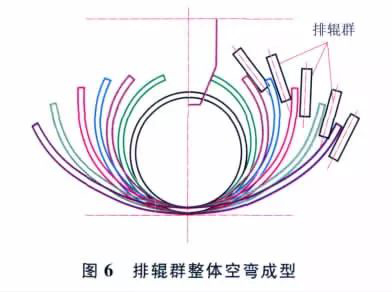

(2) Strengthen the segmented rolling of flat rolls to eliminate broken lines. That is to say, firstly, the edge of the billet is rolled with a large rolling force with the W-shaped roller and the second rough forming roller, so that the edge has no fold line feeling; then the third to fifth rough forming flat rolls are appropriately enlarged. Rolling force to eliminate bottom folds in the tube blank.

(3) Pay special attention to the balance of force on both sides of the upper flat roll, and appropriately increase the rolling force.

(4) Wrap the finished tube with a thin cloth, hold it by hand to make a spiral movement, and confirm the effect of eliminating the broken line; then add a certain rolling force in a targeted manner.

There are 4 processes in the solution to the broken line of the thin-walled pipe surface of the used welded pipe equipment. Our company has many brands and wide resources, there is always one suitable for you. You just need to tell us your pipe manufacturing needs, and our company will provide you with used welded pipe equipment that really suits your needs.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province