The relationship between welding speed and weld quality in welded pipe machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-05-04 11:30

- Pvs:

【概要描述】In the welded pipe machine, the relationship between welding speed and weld quality should be understood dialectically, and should not be neglected. It is mainly reflected in the heating stage and the crystallization stage.

The relationship between welding speed and weld quality in welded pipe machine

【概要描述】In the welded pipe machine, the relationship between welding speed and weld quality should be understood dialectically, and should not be neglected. It is mainly reflected in the heating stage and the crystallization stage.

- Sort:Information

- Auth:

- Source:

- Release time:2022-05-04 11:30

- Pvs:

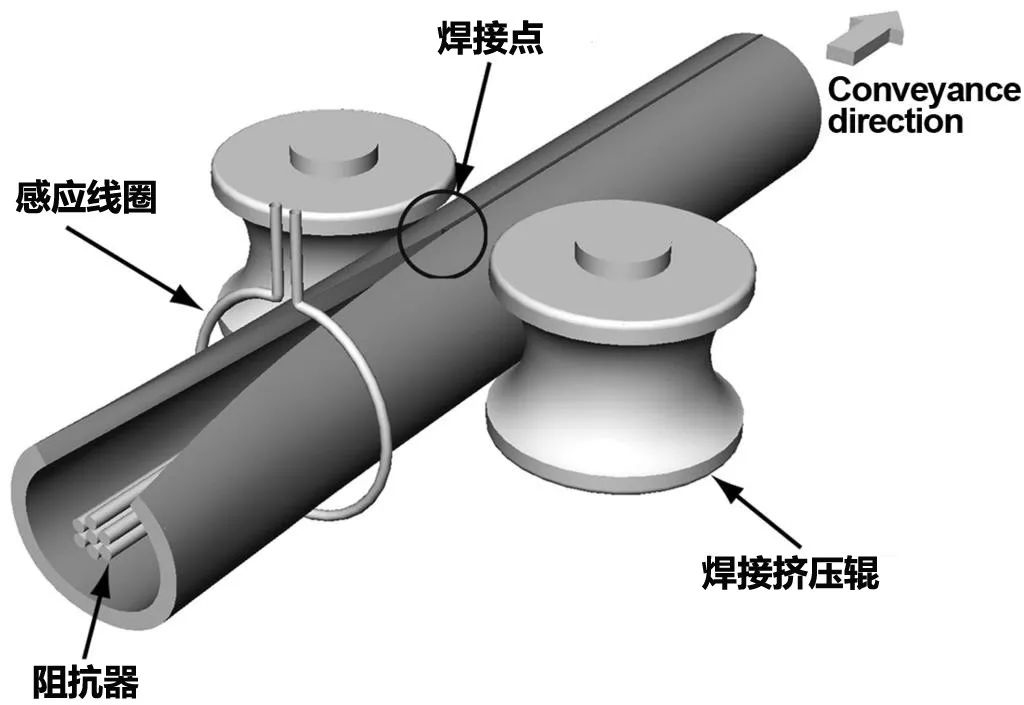

In the welded pipe machine, the relationship between welding speed and weld quality should be understood dialectically, and should not be neglected. It is mainly reflected in the heating stage and the crystallization stage.

Heating stage

Under the working condition of the welded pipe machine, the edge of the tube blank is heated from room temperature to the welding temperature. During this period, the edge of the tube blank has no protection and is completely exposed to the air, which is inevitably related to the oxygen in the air, Nitrogen reacts violently, which significantly increases nitrogen and oxides in the weld. According to the measurement, the nitrogen content in the weld is increased by 20 to 45 times, and the oxygen content is increased by 7 to 35 times. Beneficial alloying elements such as manganese and carbon are burned and evaporated in large quantities, resulting in a decrease in the mechanical properties of the weld. It can be seen that, in this sense, the slower the welding speed, the worse the quality of the weld.

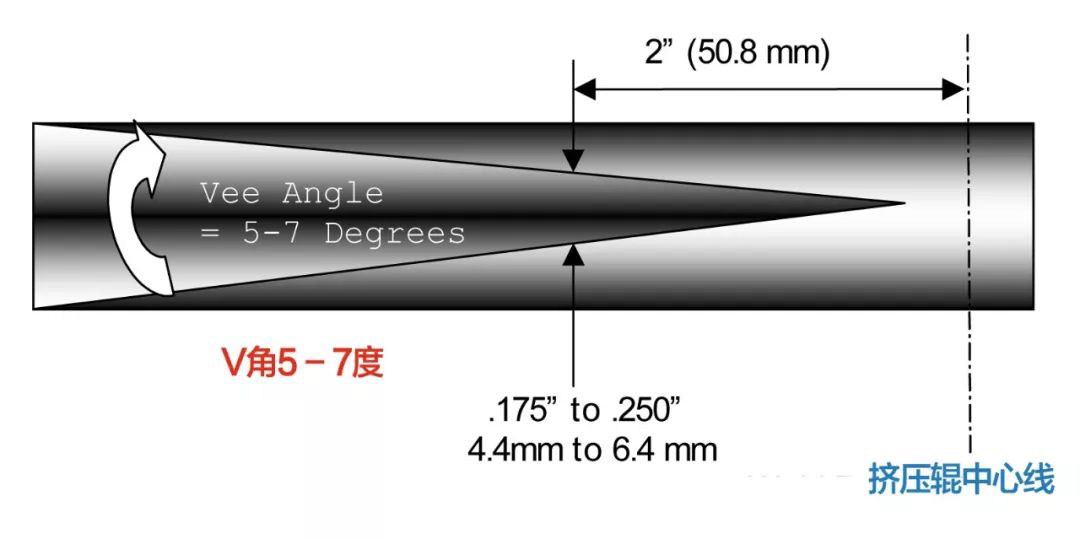

Not only that, the longer the edge of the heated tube blank is exposed to the air, that is, the welding speed is slow, which will cause the formation of non-metallic oxides in the deeper layers. It is completely extruded from the weld, and after crystallization, it remains in the weld in the form of non-metallic inclusions, forming an obvious fragile interface, thereby destroying the continuity of the weld structure and reducing the strength of the weld. The welding speed is fast, the oxidation time is short, and the non-metallic oxides produced are less and only limited to the surface layer. Oxide residue, high weld strength.

Crystallization stage

According to the principle of metallography, in order to obtain high-strength welds, the grains of the weld structure must be refined as much as possible; and the basic way of refinement is to form enough crystal nuclei in a short time, so that they are not significantly When they grow up, they come into contact with each other to end the crystallization process. This requires the welded pipe machine to increase the welding speed and let the weld quickly leave the heating zone, so that the weld can be rapidly crystallized under a large degree of subcooling; when the degree of subcooling increases, the nucleation rate can be increased. Greatly increased, the growth rate increased less, so as to achieve the purpose of refining the grain of the weld.

Therefore, no matter from the heating stage of the welding process or from the cooling after welding, on the premise of satisfying the basic welding conditions, the faster the welding speed, the better the weld quality.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province