The reason why the square and rectangular tubes produced by the directly forming to square pipe mill are all convex on all sides

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-24 11:30

- Pvs:

【概要描述】When the directly forming to square pipe mill is used to make square rectangular tubes, the tube surface will be convex, which will cause the tolerance size, tube type square, etc. to lose the angle measurement standard and size adjustment standard, and it is impossible to judge the true condition of the welded pipe.

The reason why the square and rectangular tubes produced by the directly forming to square pipe mill are all convex on all sides

【概要描述】When the directly forming to square pipe mill is used to make square rectangular tubes, the tube surface will be convex, which will cause the tolerance size, tube type square, etc. to lose the angle measurement standard and size adjustment standard, and it is impossible to judge the true condition of the welded pipe.

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-24 11:30

- Pvs:

When the directly forming to square pipe mill is used to make square rectangular tubes, the tube surface will be convex, which will cause the tolerance size, tube type square, etc. to lose the angle measurement standard and size adjustment standard, and it is impossible to judge the true condition of the welded pipe.

Eliminating the convex surface of the tube is the prerequisite for controlling the basic dimensions of the square tube manufactured by the directly forming to square pipe mill. The convex surface of the rectangular tube has four situations: single-sided convex, two-sided convex, three-sided convex and four-sided full convex. Different convex formation mechanisms are different, and adjustment methods are also different.

Convex on all sides

The reason for the four-sided convex is:

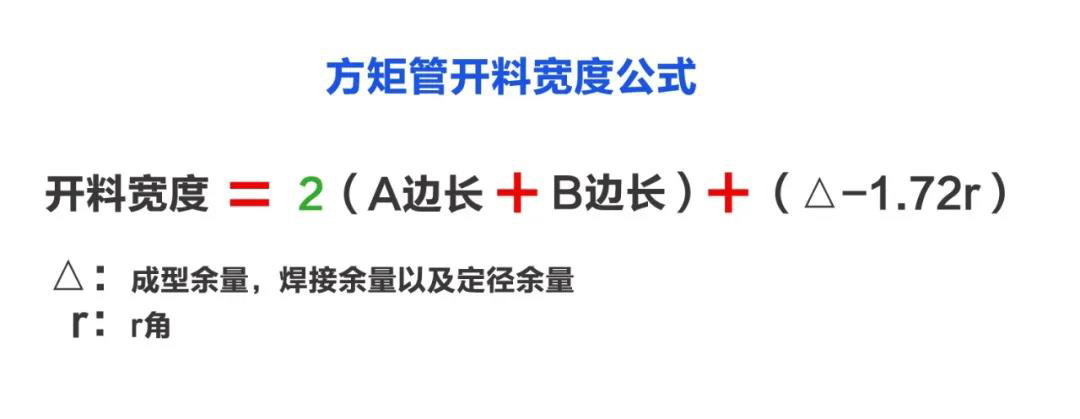

(1) The width of the cutting material is not large enough, so that the material cannot be filled with the hole. The formula for the cutting width of the rectangular tube is as follows:

(2) The pipe entering the sizing section is not big enough. In the case of sufficient cutting, if the forming allowance and welding allowance of the front section are excessively consumed, the sizing allowance after entering the sizing will become smaller.

(3) Improper allocation of sizing margin. The first few passes are pressed too much, causing most of the sizing allowance to be consumed by the first few passes, so that there is no material available for subsequent modification. It should be noted that this situation is easy to cause misjudgment, thinking that the problem lies in the insufficient cutting width, but the actual sizing margin allocation.

(4) The pipe is hard. The rectangular tube surface is flat in the final pass, and after leaving the constraints of the pass, the tube surface springs back into a convex surface under the action of the rebound inertia.

(5) The tube wall is thin. In the production of rectangular tubes with the same nominal size but different wall thicknesses, thin-walled tubes are more prone to convexity than thick-walled tubes, which is related to the insignificant neutral layer effect of thin-walled tubes.

(6) The hole pattern is severely worn. From the perspective of the working state and force of the hole pattern, the first part of the round variable square hole pattern that contacts the tube is the midpoint of the arc of each section of the hole pattern. Easy to bulge.

When the directly forming to square pipe mill produces square rectangular pipes, the convex surface problem of the square rectangular pipe will occur. Different convex surfaces are formed for different reasons. If you want to adjust, you must know the reasons for the formation of full convexity on all sides.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province