The method of directly forming to square pipe mill to adjust the r angle of the square tube

- Sort:Information

- Auth:

- Source:

- Release time:2021-10-14 12:00

- Pvs:

【概要描述】When the square tube is manufactured by the directly forming to square pipe mill, the r-angle symmetry and the same size of the square tube are important conditions to measure the external beauty of the square tube, and it also affects the subsequent assembly requirements of the finished tube tooling.

The method of directly forming to square pipe mill to adjust the r angle of the square tube

【概要描述】When the square tube is manufactured by the directly forming to square pipe mill, the r-angle symmetry and the same size of the square tube are important conditions to measure the external beauty of the square tube, and it also affects the subsequent assembly requirements of the finished tube tooling.

- Sort:Information

- Auth:

- Source:

- Release time:2021-10-14 12:00

- Pvs:

When the square tube is manufactured by the directly forming to square pipe mill, the r-angle symmetry and the same size of the square tube are important conditions to measure the external beauty of the square tube, and it also affects the subsequent assembly requirements of the finished tube tooling.

To According to international standards, if there is no special requirement, the r angle of the finished pipe should be adjusted according to 1.5t (wall thickness). However, in actual production, the four r angles are often unequal. Some customers will require the r angle to be greater than 1.5 or less than 1.5 wall thickness according to the use of the finished pipe. Therefore, the manufacturer is required to effectively control the r angle according to the process requirements to meet different needs.

When using the directly forming to square pipe mill to manufacture square rectangular pipes, there are three adjustments for the r angle greater than 1.5 or less than 1.5 wall thickness.

Adjustment of r<1.5t

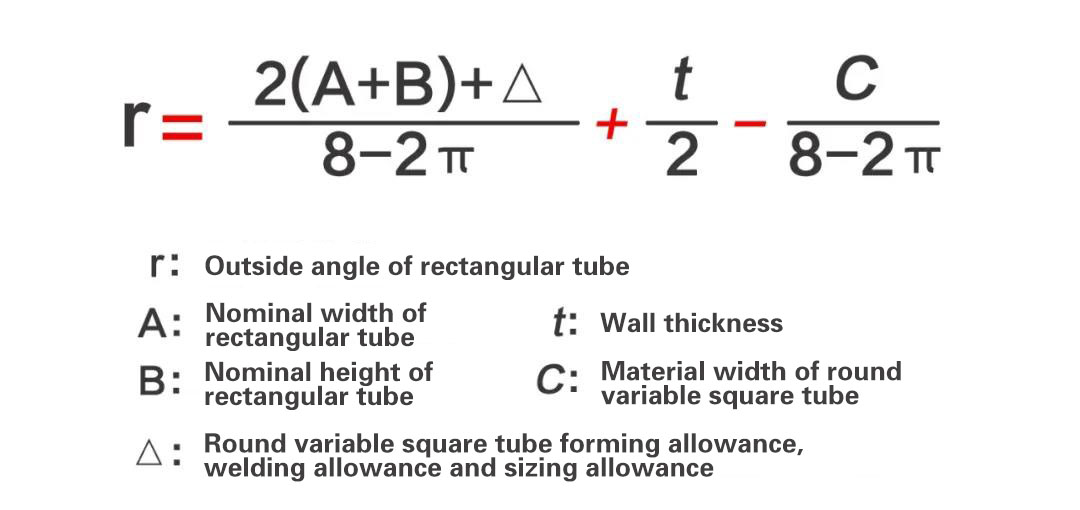

(1) Increase the bandwidth and reduce the r angle. According to the calculation formula of the material width of the circular variable square tube:

In the formula, for a specific welded pipe, A, B, t and △ are fixed values. To make r smaller, the most direct way is to increase C. After the width of the tube blank is widened, the increase will make the round tube larger before the square is rounded, and more material will fill the gap at the corner of the rectangular tube pass. The more the filler, the sharper the corner.

Adjustment of r>1.5t

The adjustment method is opposite to the above-mentioned situation.

r angle symmetry adjustment

Judging from the practice of manufacturing square rectangular tubes with directly forming to square pipe mill, the difficulty of controlling the r angle of the square rectangular tube is not simply whether it is large or small, but whether it is symmetrical. The symmetry of the r angle, in addition to adjustment, is also closely related to the hole design.

There are three design methods for the angle r when designing the rectangular tube pass.

(1) Specific r-angle hole type. The characteristic of the obliquely specific r-angle pass is: each roll pass is composed of five arcs, that is, two main deformation arcs and three r arcs are connected by tangent, and the pass is gradually designed to be a specific The r angle.

The only advantage of this pass is the high accuracy of the r-angle, and the four corners are easy to be symmetrical and equal, but this is also its fatal shortcoming-a set of rolls can only produce the only rectangular tube with the r-angle shape. Unless the customer has special regulations and requirements for the r angle, such a design is generally not made.

(2) Sharp-angle hole type. The characteristic is that the hole-shaped arc intersects the arc. The advantage of this type of pass is strong adaptability. The same pass can meet the requirements of different customers for different fillets. By controlling the width of the tube blank and proper on-site adjustment, it can completely ensure that the four corners of the rectangular tube are within a certain accuracy range. Symmetry is equal. However, this requires relatively high requirements for the commissioning personnel. If the adjustment is improper, even a hole with a specific r-angle may produce a rectangular tube with asymmetrical four corners.

(3) No angle hole type. The characteristic is that the hole pattern lines do not intersect, and the r-angle does not exist. For example, the hole pattern for the universal arch deformed rectangular tube and the hole pattern that uses the Turkish head method to participate in the deformation. This type of hole pattern is actually the inheritance and development of the sharp-angled hole pattern.

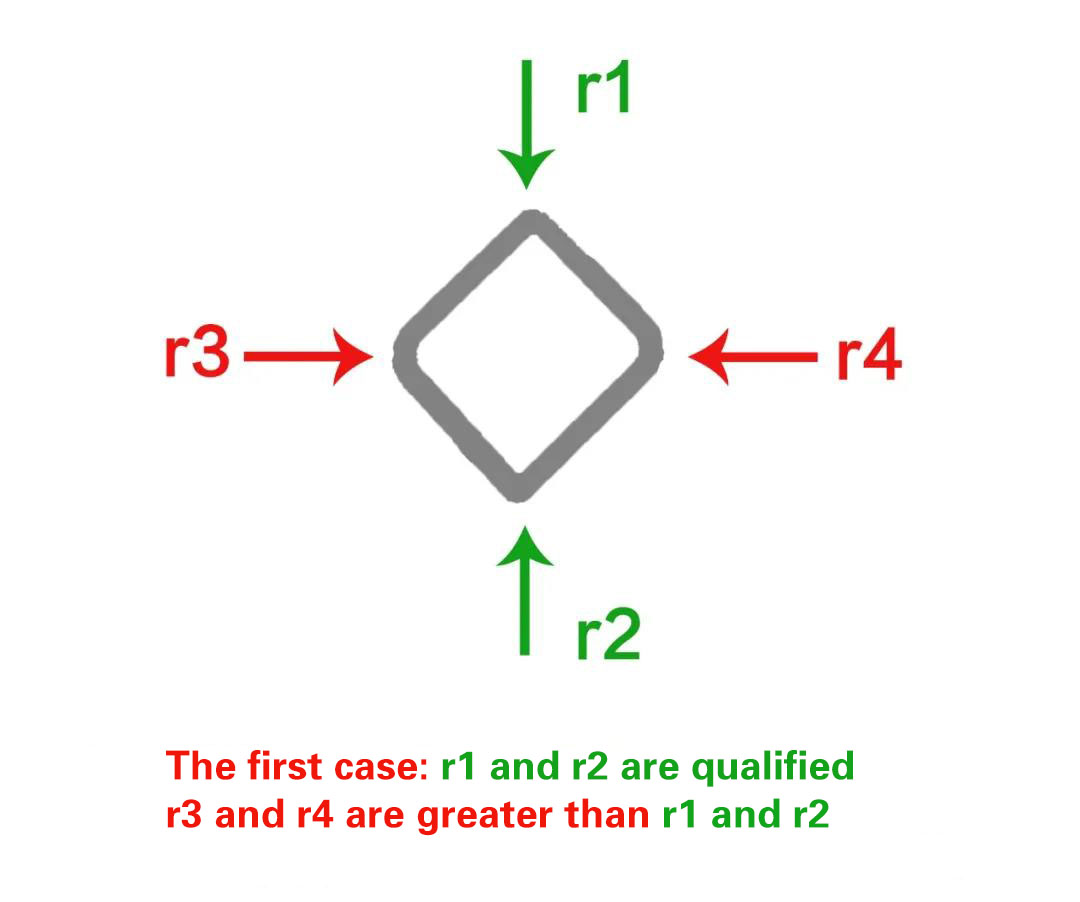

There are four basic forms and adjustments for the unqualified r angle when making square rectangular tubes with directly forming to square pipe mill:

(1) The adjustment of the lateral r angle of the rectangular tube that does not meet the standard.

As shown in the first case in the above figure, r2 and r4 are too large for the obliquely exiting square tube. The main adjustment measures are:

Properly loosen the vertical roller, and at the same time properly press down the flat roller (whether or not the last flat roller is also pressed depends on the tolerance). When the tolerance is in place, loosen the first few vertical rollers a little to keep the last flat vertical roller basically stationary . It is also possible to separately press down one or two flat rollers with little change in r angle after passing through the flat roller hole type according to the specific situation. If r2 and r4 are too small, reverse adjustment is performed.

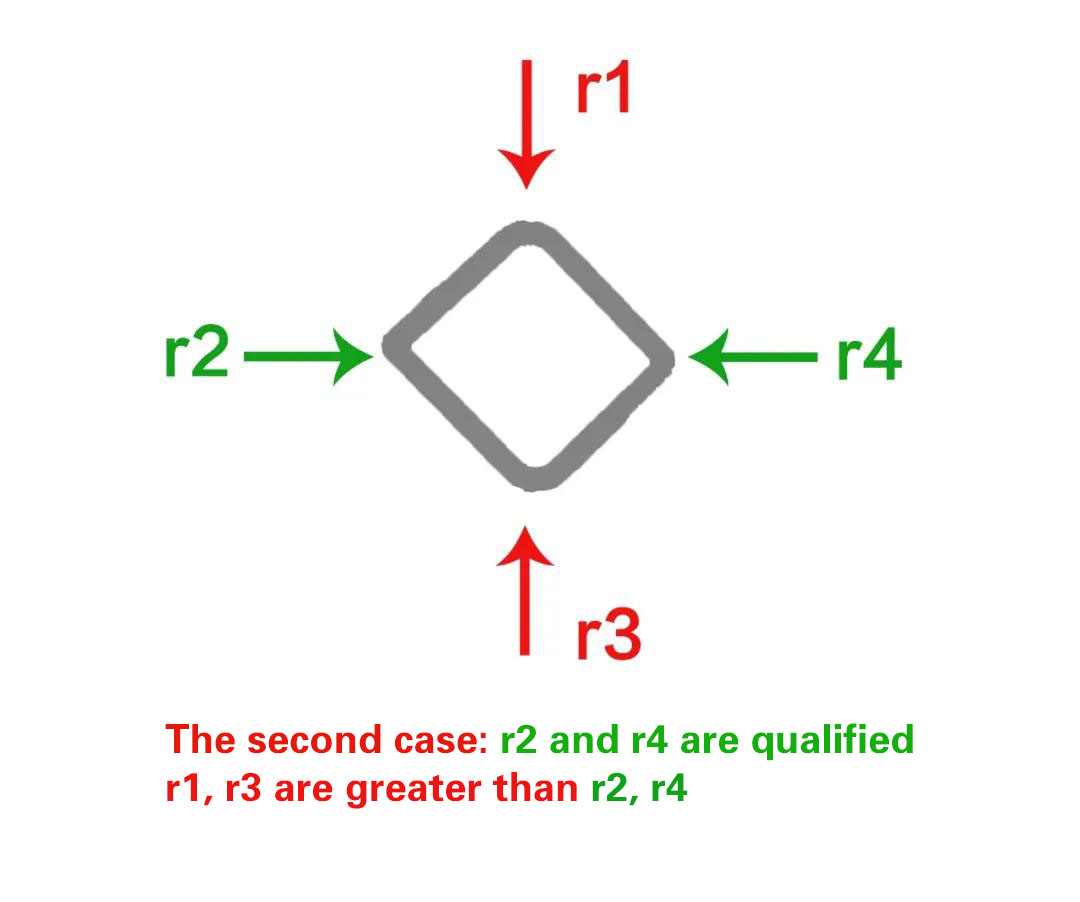

(2) Adjust the vertical angle r of the rectangular tube that does not meet the standard.

In the second case of the above figure, the oblique rectangular tube r1 and r3 are too large. The guiding ideology of the disposal method is to relax the flat roll and gather the vertical roll as the basic adjustment method, and directly roll the small roll gap with the edge of the vertical roll pass. Angle r1 and r3. The purpose of relaxing the flat roll is to increase the upper and lower dimensions of the tube blank to facilitate the rolling of the vertical roll pass edge to reduce r1 and r3; the second is to achieve a relative reduction of r1 and r3 by increasing r2 and r4; the third is to reduce r1 for the vertical roll And r3 prepare more materials.

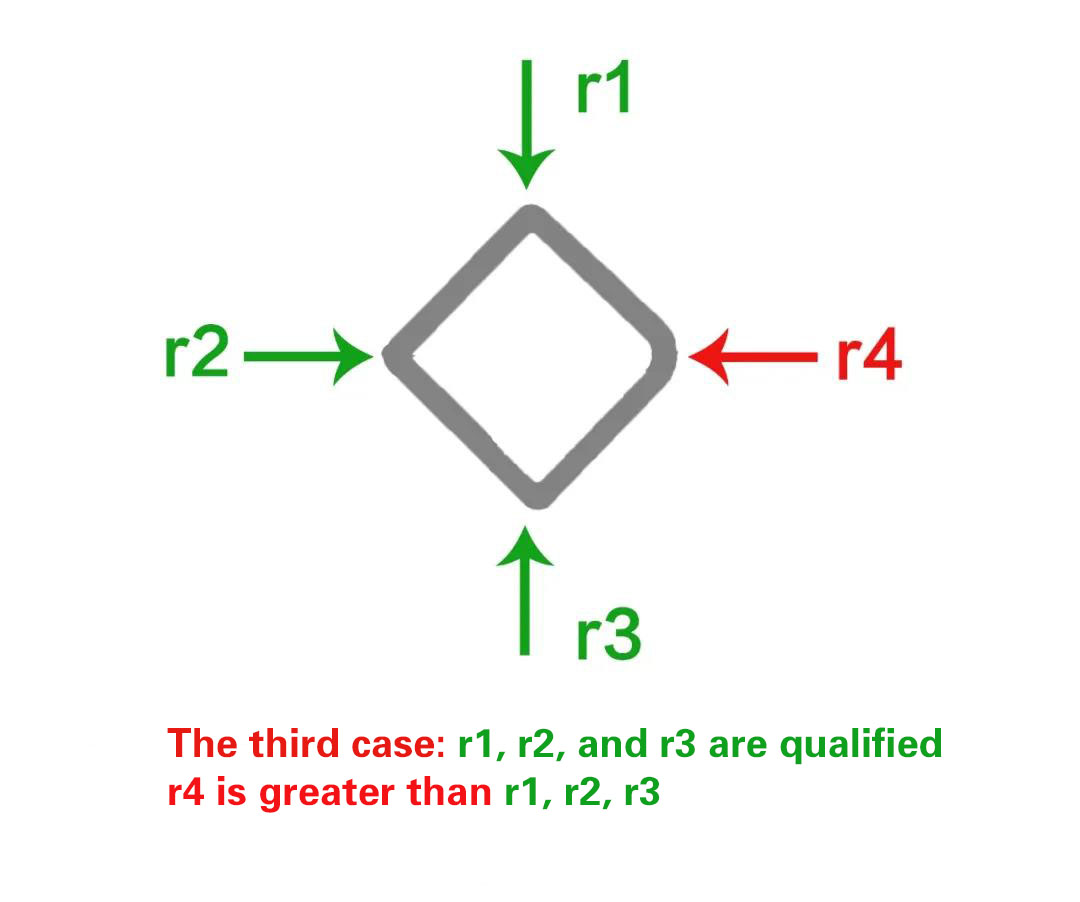

(3) Adjust the angle r on the lateral side of the rectangular tube that does not meet the standard.

If r4 is too large (as shown in the figure above), after observing and analyzing the specific situation, you can try to make the following adjustments:

First: properly press down the flat roll on the side of r4, and directly roll the small r4;

Second: You can also move the penultimate first and second vertical rollers a little in the direction of r4. This action actually forces the angle of r4 to drill into the gap of the flat roller on the side of r4, thereby aggravating the rolling of the edge of the side pass to the angle of r4. Braking force, reduce r4.

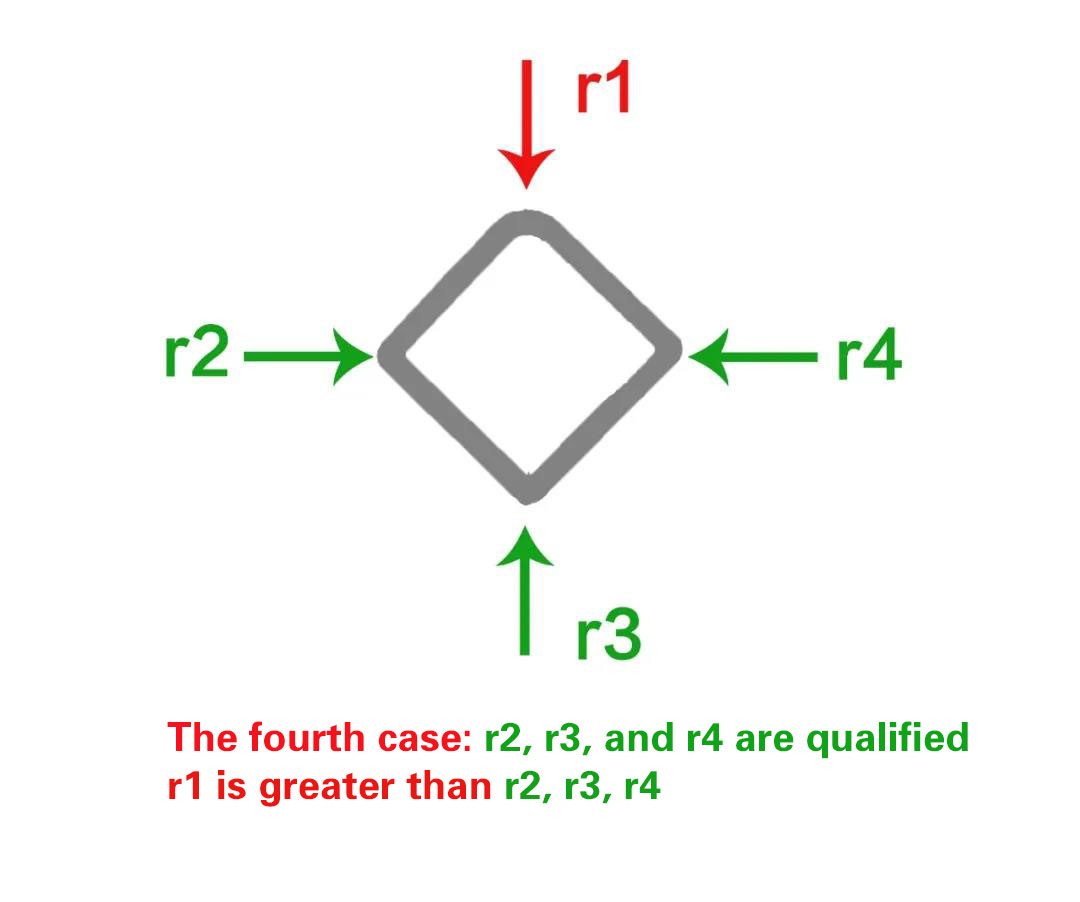

(4) The adjustment of the upper (lower) angle r of the rectangular tube is not up to the standard.

If r1 is too large (as in the fourth case in the above figure), on the basis of fully observing and analyzing the current situation of the sizing roller, the following adjustments can be made:

First: appropriately narrow the upper roll gap of the vertical roll to increase the rolling force at the r1 corner of the rectangular tube at the upper edge of the vertical roll pass, thereby reducing r1;

Second: Appropriately lower the penultimate vertical roll. This action is actually to increase the rolling force at the angle r1 of the rectangular tube at the upper edge of the vertical roll pass and reduce r1.

Third: Raise the upper roller. If the r1 of the nth to the vertical roller is too large, the n-1th flat roller can be properly raised.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province