The method of adjusting the concave surface when the galvanized pipe machine manufactures the square tube

- Sort:Information

- Auth:

- Source:

- Release time:2022-10-02 11:30

- Pvs:

【概要描述】When the galvanized pipe machines manufactures rectangular pipes, the pipe surface may be concave or convex. Concave surface classification is similar to convex surface.

The method of adjusting the concave surface when the galvanized pipe machine manufactures the square tube

【概要描述】When the galvanized pipe machines manufactures rectangular pipes, the pipe surface may be concave or convex. Concave surface classification is similar to convex surface.

- Sort:Information

- Auth:

- Source:

- Release time:2022-10-02 11:30

- Pvs:

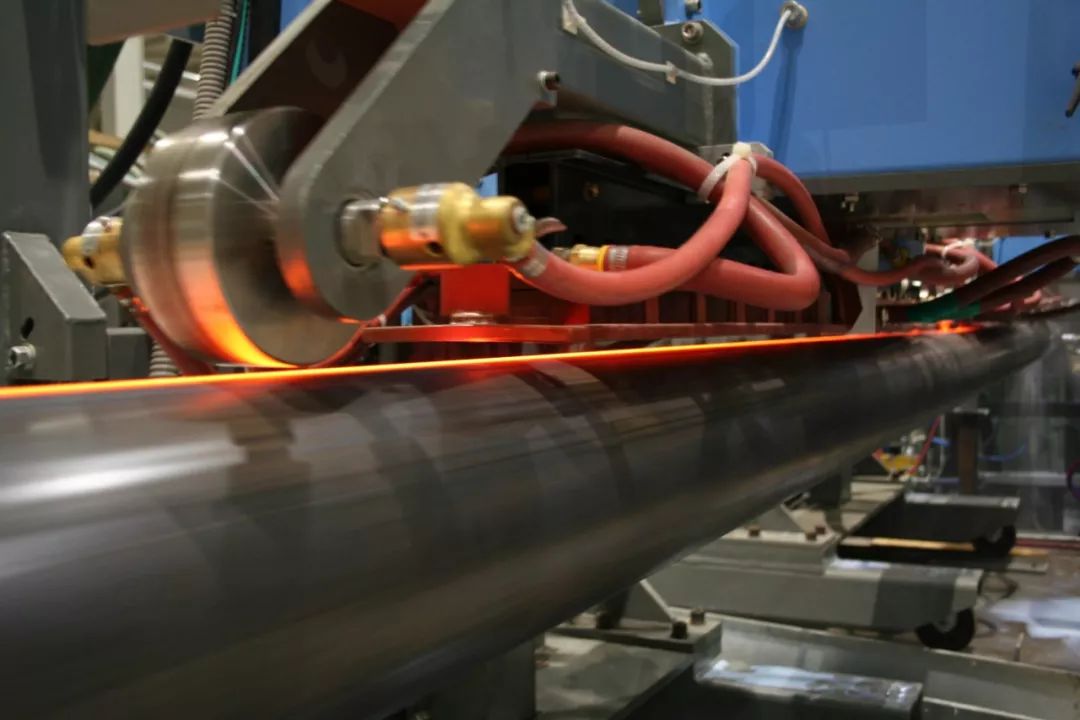

When the galvanized pipe machines manufactures rectangular pipes, the pipe surface may be concave or convex. Concave surface classification is similar to convex surface. The concave surface of rectangular tube is also divided into four-sided concave, three-sided concave, two-sided concave and single-sided concave. Because the position of the concave surface is different, the causes and the measures to eliminate the concave surface are also different.

The mechanism of the concave surface is that when the longer rectangular tube edge enters the smaller end flat pass, the outside of the billet is restricted by the pass rolling force, and the section longer than the pass can only go into the empty tube cavity. Instability, resulting in a depression on the surface of the pipe. It can be seen that the side length of the tube blank, which is much longer than the side of the hole, exceeds the length that the hole can accommodate, which is the root cause of the surface depression of the square tube.

Measures for Adjusting the Concave Surface of Rectangular Pipe Made by Galvanized Pipe Machine

Because the mechanism of the concave surface is exactly the opposite of the main reason for the convex surface, many adjustment measures for the concave surface when processing the galvanized pipe machines to manufacture square rectangular tubes must be carried out around shortening the concave surface. This means that many measures to adjust the convex surface tube can be used to eliminate the tube surface depression as long as the reverse is reversed.

Adjustment of bump (wave) surface

The difficulty of adjusting the concave and convex surface of the rectangular tube is far greater than that of a simple concave or convex surface. Because there are both concave and convex surfaces on the same plane. The method of judging the unevenness of the rectangular tube surface is to use an edge of a straightedge to close the tube surface and look at the light, and judge according to the light transmission position.

The cause of the uneven surface of the rectangular tube:

Through a large number of physical observations, it is found that most of the rectangular tube surfaces with unevenness are composed of straight lines (or arcs with a large radius of curvature) of varying length and length, and concave arcs of varying sizes. There are several aspects to determine the cause of the uneven surface:

(1) Indentation. For example, if the squeezing force is too large or the squeezing roll is too high, the tube blank will inevitably run to the roll gap, forming up and down "sharp peaches". The "pointed peach" forms a small convex arc, and a small concave arc is formed near the inflection point of the "pointed peach". In the subsequent fasting rolling process, the "pointed peach" is flattened by the pass, and the edge small concave arc follows. The "pointed peach" was simultaneously pressed down, and then remained on the surface of the rectangular tube forever.

In fact, such "pointed peaches" can be produced in both sizing vertical rolls and forming horizontal vertical rolls. The difference lies in different degrees.

(2) "Corner". According to the basic theory of round to square, after the tube blank is divided into the first pass of the square tube, the embryonic shape of each corner on the welded pipe has been formed, and the relative spatial position of the corner and the corner have also been fixed. The radius of curvature changes, and the mutual position cannot be changed (except for each section of micro-reduction).

However, when the process of changing the direction of the welded pipe is unstable, the position of the deformed angle on the pipe with respect to the rear face angle will change. Since the four corners move in one direction at the same time, it is commonly called "corner". After the corner occurs, the convex arc of the original corner of the tube is transferred to the pass plane. During the process of rolling and "flattening" the convex arc, the convex arc deforms inertial force, and the points on both sides of the convex arc are stressed at the same time. When the convex arc is pressed down synchronously with the apex of the convex arc, when the convex arc is basically flattened under the direct action of the pass rolling force, the points on both sides of the convex arc must be lower than the apex of the convex arc to form a concave surface, which forms a concave surface relative to the apex of the convex arc. Waves on both sides.

(3) Dislocation of hole pattern. For example, if the flat rolls with closed holes are misaligned, the forming tube blank will be rolled at the roll gap. The indentation will more or less leave a dent on the plane of the finished square tube. When the dent and the plane coexist It becomes a bumpy surface.

(4) The hole type is worn. Take only the serious wear of the closed-hole flat roller as an example, the formed tube blank of the closed-hole roller will be out of round and become a "diamond-shaped" tube. When the four corners of the "diamond" tube (plus the opening) and the corners of the hole pattern cannot be mapped to each other, the result is similar to the "corner", forming a rectangular tube wave surface.

(5) Wall thickness. The tube wall is thin, and it is especially easy to be dented; for an empty tube, once a dent is formed, it cannot be restored to a level. Therefore, in the production of welded pipes, the problem of uneven surface of thick-walled rectangular pipes is relatively rare.

(6) The size of the welded pipe to be reshaped. The shaping margin is large, and each segment is squeezed more in the circumferential direction, which intensifies the depth of the existing concave arc on the pipe surface, and makes the inconspicuous concave arc obvious. On the contrary, the shaping margin is small, and the concave arcs can be freely used in the hole pattern, at least not deepening the concave arcs.

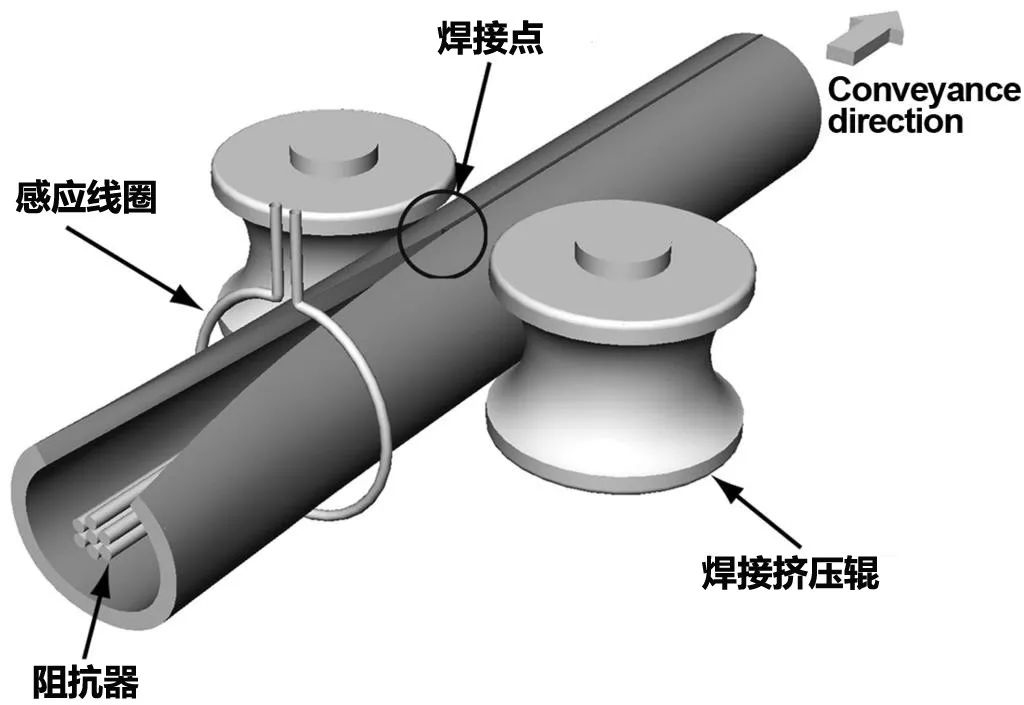

Adjustment of concave and convex surface of rectangular tube. It is necessary to focus on preventing the misalignment of the pass, indentation, "sharp peach" and "swivel-corner", and carefully adjust the galvanized pipe machines mainly including forming, welding and sizing rolls to ensure that the pass is symmetrical; coordinate the longitudinal tension and transverse tension of the whole machine The rolling force ensures the temperature operation of the welded pipe and avoids "weld seam deflection"; timely repairs the severely worn roll pass.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province