The key technology of precision welded pipe production by used welded pipe machine—Welded pipe forming process

- Sort:Information

- Auth:

- Source:

- Release time:2022-10-27 11:30

- Pvs:

【概要描述】Used welded pipe machine often consider many key technologies when producing precision welded pipes, such as ① quality requirements for raw materials, ② welded pipe forming process, ③ formation and removal of weld burrs, ④ weld heat treatment, ⑤ non-destructive testing, ⑥ correct Equipment requirements for welded pipe unit. For this reason, we will introduce the quality requirements of raw materials to be considered in the production of precision welded pipes.

The key technology of precision welded pipe production by used welded pipe machine—Welded pipe forming process

【概要描述】Used welded pipe machine often consider many key technologies when producing precision welded pipes, such as ① quality requirements for raw materials, ② welded pipe forming process, ③ formation and removal of weld burrs, ④ weld heat treatment, ⑤ non-destructive testing, ⑥ correct Equipment requirements for welded pipe unit. For this reason, we will introduce the quality requirements of raw materials to be considered in the production of precision welded pipes.

- Sort:Information

- Auth:

- Source:

- Release time:2022-10-27 11:30

- Pvs:

Used welded pipe machine often consider many key technologies when producing precision welded pipes, such as ① quality requirements for raw materials, ② welded pipe forming process, ③ formation and removal of weld burrs, ④ weld heat treatment, ⑤ non-destructive testing, ⑥ correct Equipment requirements for welded pipe unit. For this reason, we will introduce the quality requirements of raw materials to be considered in the production of precision welded pipes.

Precision welded pipes are more accurate in geometric dimensions than general welded pipes, and the welds and inner and outer surfaces are of good quality, and the wall thickness is uniform. It can be used in equipment components directly or with a small amount of processing. It is widely used in chemical, textile machinery, aviation, instrumentation, automotive and other sectors. .

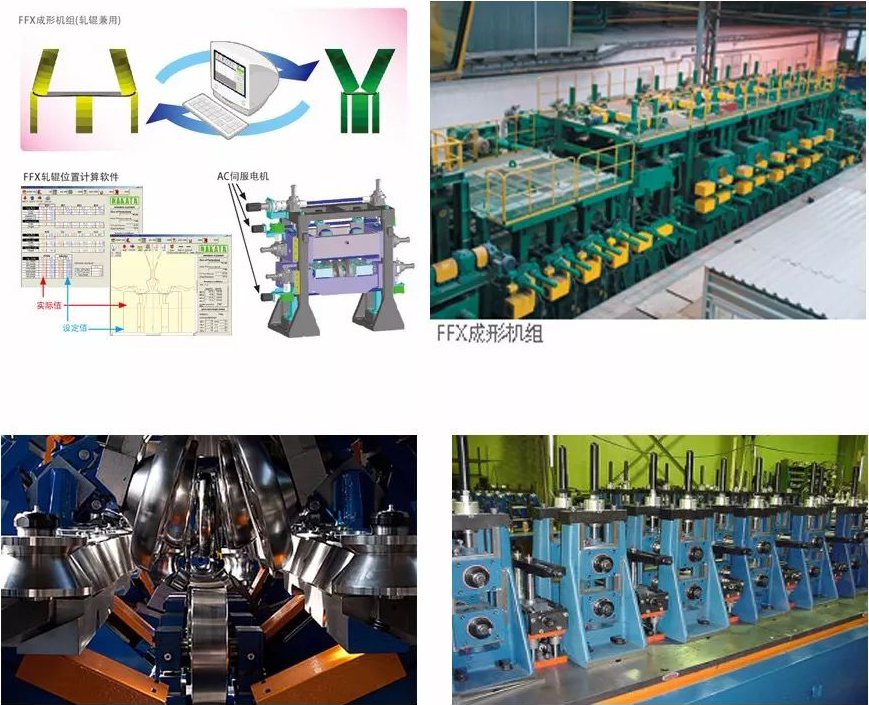

When making welded pipes in used welded pipe machine, they will go through a procedure welded pipe forming process, that is, the welded pipe unit forming and sizing part pass design and adjustment methods will directly affect the quality of welding. The traditional forming process is a roll forming process, with single radius and double radius; W reverse bending method to form the hole pattern system, plus two rolls, three rolls, four rolls or five rolls squeeze rolls, two rolls or four rolls sizing To ensure the forming quality. This traditional roll forming process is mostly used in used welded pipe machine with a diameter less than Φ114mm. It has a good guarantee for the shape of the welded joint and good surface quality after forming, and it is suitable for used welded pipe machine with a wider range of specifications. Various forming process technologies have different advantages and disadvantages and are suitable for different conditions. According to the product outline and product use, careful consideration should be given to the selection of different forming process technologies in the selection of equipment.

In order to reduce the elastic deformation, the processing and deformation passes of precision welded pipes made by used welded pipe machine are correspondingly increased by 2 to 3 passes compared with ordinary welded pipes. In the deformation arrangement, the initial deformation angle should be reduced to ensure stable biting, the middle bending angle should be appropriately increased, and the rear deformation should be appropriately reduced. Increasing the number of deformation passes not only reduces the deformation force, but also releases the strip. The chance of surface stress makes the gradient of surface stress increase slowly, which can avoid cracks. In the adjustment process, first of all, ensure that the various passes of the vertical centerline are unified, and use the center as the base axis to find the positioning size and the middle sleeve. At the position of the horizontal line, the uphill line (downhill line) should be formed according to the process arrangement. Straight line, no curve jumps. Before the belt is worn, the hole shape of each rack should be adjusted, and the size of each pass should be measured to ensure that the product enters each rack stably. The force must be balanced during the adjustment, and the force cannot be deformed on a frame to ensure stable and uniform changes in the lifting angle.

In the production of precision welded pipes by used welded pipe machine, controlling and adjusting the forming and sizing stand equipment accumulated errors and roll bouncing of the welded pipe unit is the key to the production of precision welded pipes by older welded pipe units.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province