Suggestions for preventing defects of high frequency welded pipe machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-16 11:30

- Pvs:

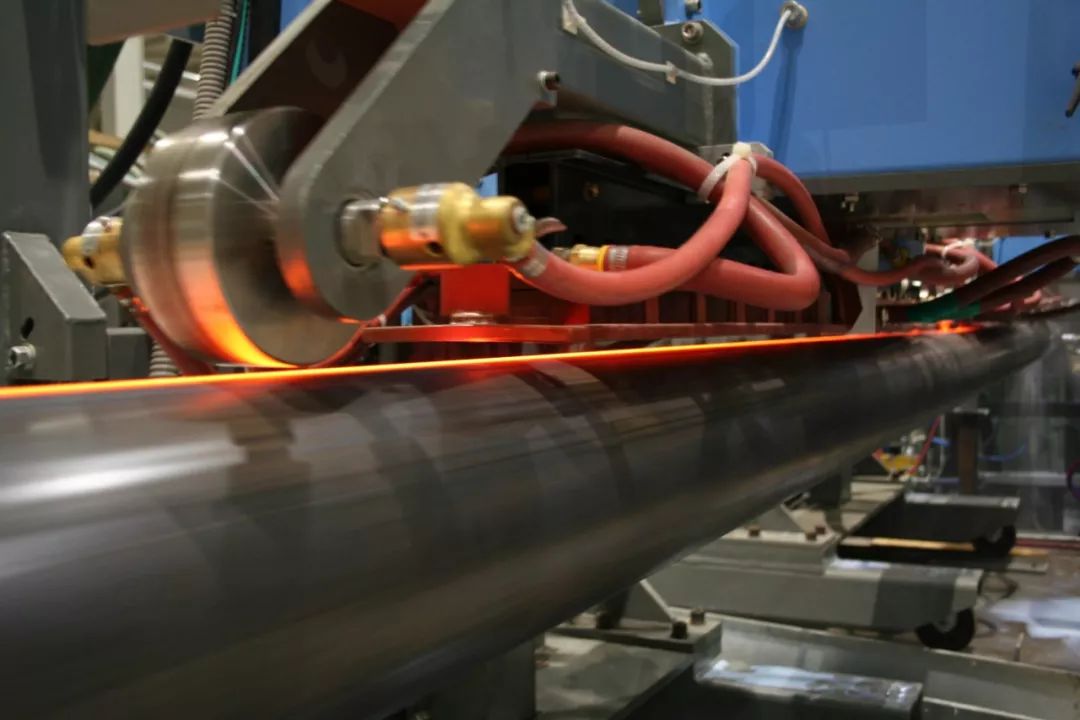

【概要描述】In the actual production of high frequency welded pipe machine, several factors are often combined to produce defects. A narrow V-shaped mouth does not necessarily produce superburned oxides, unless the extrusion amount is slightly less than a normal value. The small amount of extrusion may be caused by the slightly narrow slitting width of the steel strip or the improper installation of the tooling and wear equipment.

Suggestions for preventing defects of high frequency welded pipe machine

【概要描述】In the actual production of high frequency welded pipe machine, several factors are often combined to produce defects. A narrow V-shaped mouth does not necessarily produce superburned oxides, unless the extrusion amount is slightly less than a normal value. The small amount of extrusion may be caused by the slightly narrow slitting width of the steel strip or the improper installation of the tooling and wear equipment.

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-16 11:30

- Pvs:

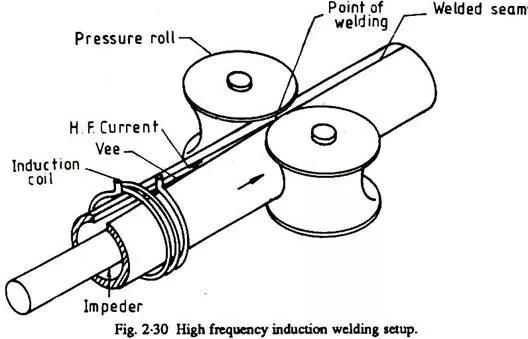

In the actual production of high frequency welded pipe machine, several factors are often combined to produce defects. A narrow V-shaped mouth does not necessarily produce superburned oxides, unless the extrusion amount is slightly less than a normal value. The small amount of extrusion may be caused by the slightly narrow slitting width of the steel strip or the improper installation of the tooling and wear equipment.

There are also reasons for welding defects outside the welding zone. For example, cold welding may be caused by the evacuation of the cooling pump, and the magnetic rod cannot be sufficiently cooled. The magnetic rod becomes hot instantly, which reduces the heat concentrated in the V-shaped mouth and causes cold welding. Increasing the welding input can prevent cold welding defects from occurring until the cooling pump is completely inoperative and the magnet bar completely fails.

The best way to prevent defects is to find out the root causes of defects, and try to collect various operating parameters that may cause defects in high frequency welded pipe machine. Determine the relevant parameters, such as working width, welding speed, screen flow, screen current, extrusion amount and other, observe the actual operation, and record to find abnormal fluctuations and analyze the causes of defects. During production, the set value may be slightly higher than the normal value, but several related variables are slightly exceeded at the same time, and the cumulative result shows that it is enough to produce defects.

In the production process of high frequency welded pipe machine, the common defects and their causes are analyzed, classified and summarized, which is very beneficial to operators with experience in defects, which can not only improve efficiency, but also reduce costs.

Overview

(1) Most of the welding defects are caused by improper installation or commissioning of the unit;

(2) Selecting a reasonable manufacturing scheme, monitoring daily operation records, and regularly training high-frequency welders will help reduce defects;

(3) Improve the quality of edge trimming and edge treatment and the coil energy storage process, which is beneficial to edge loss defects;

(4) Pre-repair can prevent tool wear.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province