Squeeze roll hole pattern and upper pressure of steel slitting machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-05-09 11:30

- Pvs:

【概要描述】The squeeze roll is the most important roll in the production of steel slitting machine, and it is the force exerting force of the squeezing force in the three elements of welding. The hole type can be divided into single-radius, double-radius, ellipse, groove and special-shaped. Among them, the hole type of the single-radius extrusion roll is the most representative.

Squeeze roll hole pattern and upper pressure of steel slitting machine

【概要描述】The squeeze roll is the most important roll in the production of steel slitting machine, and it is the force exerting force of the squeezing force in the three elements of welding. The hole type can be divided into single-radius, double-radius, ellipse, groove and special-shaped. Among them, the hole type of the single-radius extrusion roll is the most representative.

- Sort:Information

- Auth:

- Source:

- Release time:2022-05-09 11:30

- Pvs:

The squeeze roll is the most important roll in the production of steel slitting machine, and it is the force exerting force of the squeezing force in the three elements of welding. The hole type can be divided into single-radius, double-radius, ellipse, groove and special-shaped. Among them, the hole type of the single-radius extrusion roll is the most representative.

Single Radius Squeeze Roll Pass

The single-radius extrusion roller hole pattern, as the name implies, means that the hole pattern is composed of a single radius. According to the different extrusion devices of steel slitting machine, there are single-radius two-roller, three-roller and multi-roller types, while the two-roller single-radius extrusion roller pass is the most widely used, the longest history, and the most experienced in the welded pipe industry. Rich.

The working principle of the two-roll squeeze roller

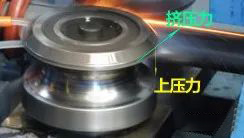

When the forming tube enters the extrusion roller hole, on the one hand, the edge of the tube blank is rapidly heated to 1250~1450°C by high-frequency current, and at the same time, it is subjected to a strong extrusion force F, which makes it in a molten state and is extruded together. The edges of the tube blanks crystallize each other to form welds, internal burrs and external burrs; on the other hand, under the action of strong extrusion force, the edge of the tube blank always has a tendency to run out of the roll gap, and the upper edge of the hole pattern forms a pair of The upper pressure f on the edge of the tube blank. The so-called upper pressure refers to the radial force on the edge of the tube blank, which is derived from the extrusion force and is located at the uppermost edge of the hole pattern of the extrusion roll.

This force is crucial to achieve parallel butt joints at the edges of the tube blank and weld seam quality. If the upper pressure f is large, the control ability of the edge of the tube blank will be strong, which can effectively restrain the edge of the tube blank from running out of the roll gap and ensure the parallel butt joint of the welding seam. Run at the seam, forming a sharp peach shape, which in turn affects the strength of the weld. For a long time, the effect of the pressure on the hole type of the extrusion roller has not really attracted enough attention. It is no exaggeration to say that although the upper pressure is derived from the extrusion force, its effect on the welding quality is very important. Even more than the squeezing force itself.

The relationship between squeezing force and upper pressure

When we use traditional squeezing rollers to apply squeezing force in steel slitting machine, we often encounter such an embarrassing situation: we know that the burr on the outside of the weld is already very large, and the squeezing force cannot be increased, but the strength of the weld is based on the strength of the weld. For this reason, we have to continue to increase the extrusion force. However, after decomposing the extrusion force, it is found that, at this time, what is needed to enhance the strength of the weld is not the extrusion force, but the upper pressure. In other words, the upper pressure of the traditional extrusion roll hole type is seriously lacking, and only a small amount of the extrusion force is converted into the upper pressure.

Measures to Enhance Pressure on Squeeze Roller Hole

The measures to enhance the air pressure on the traditional two-roll squeeze rollers can be started from the following four aspects:

(1) Minimize the chamfer on the upper edge of the upper hole type as much as possible.

(2) Appropriately reduce the gap between the squeeze rollers. Reducing the roll gap directly moves the upper pressure application point to the edge of the tube blank, but this reduction is extremely limited.

(3) Correctly adjust the squeeze roller. The actual roll gap of the squeeze roller has three conditions: the same up and down, the upper part is large and the lower part is small, and the upper part is small and the lower part is large.

(4) Select the appropriate squeeze roller hole radius. The larger the hole type, the weaker the upper pressure, and vice versa, the stronger the upper pressure.

Part of the content of this site comes from the Internet. This site only provides information storage. The copyright belongs to the original author. It does not bear the relevant legal responsibility and does not represent the views and positions of this site. Please contact and delete it if there is any infringement.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province