Solutions to difficulties in thick-walled pipe forming of directly forming to square pipe mill (1)

- Sort:Information

- Auth:

- Source:

- Release time:2023-06-06 11:30

- Pvs:

【概要描述】Solutions to solve the difficulties in forming thick-walled tubes of directly forming to square pipe mill include special forming unit solutions, rough forming pass solutions, fine forming pass solutions and comprehensive solutions. Let me introduce the solution to the difficult forming of thick-walled tube(1).

Solutions to difficulties in thick-walled pipe forming of directly forming to square pipe mill (1)

【概要描述】Solutions to solve the difficulties in forming thick-walled tubes of directly forming to square pipe mill include special forming unit solutions, rough forming pass solutions, fine forming pass solutions and comprehensive solutions. Let me introduce the solution to the difficult forming of thick-walled tube(1).

- Sort:Information

- Auth:

- Source:

- Release time:2023-06-06 11:30

- Pvs:

Solutions to solve the difficulties in forming thick-walled tubes of directly forming to square pipe mill include special forming unit solutions, rough forming pass solutions, fine forming pass solutions and comprehensive solutions. Let me introduce the solution to the difficult forming of thick-walled tube(1).

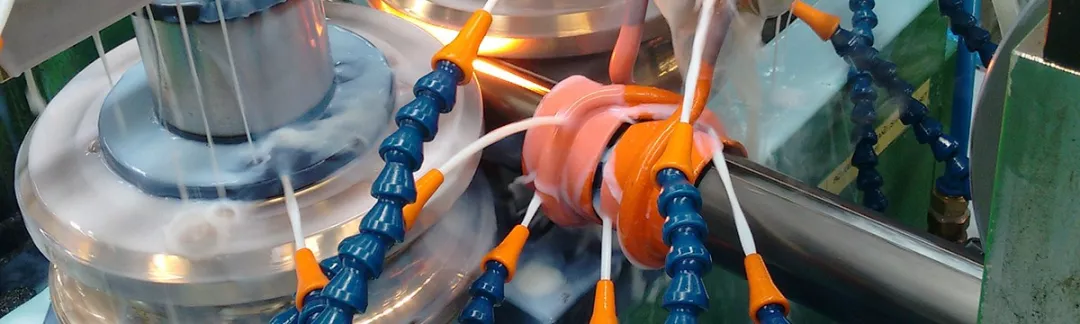

Dedicated forming unit solution

The directly forming to square pipe mill can be divided into large and medium-sized welded pipe mills or special thick-walled pipe mills. Most of them are equipped with edge planers or milling machines. Before the flat tube billet enters the first forming flat roll, the raw material edge is planed and milled in advance. Realize parallel butt joints of welds. This scheme is relatively mature and applied in the welded pipe industry. The disadvantage is that the investment is large, especially for small welded pipe units, which is relatively large.

Rough forming pass solution

The basic idea of applying the edge double-radius W hole type to solve the difficulties of thick-walled pipe forming is to respect the deformation characteristics of thick-walled pipe’s wide deformation blind zone, large springback and large difference between inner and outer circumferences, and implement the implementation of the billet within the range of several times the deformation blind zone. Excessive deformation. In other words, if there is no deformation blind zone and springback, the formed tube will show a ∧-shaped butt state; when the deformed tube blank has a deformation blind zone and springback, it will just reach a parallel butt state. In this way, although the deformation blind zone cannot be eliminated, the edge V-shaped butt joint can be eliminated, and the process goal of the parallel butt joint of the weld seam can be achieved. The double-radius W hole pattern at the edge can eliminate the influence of the V-shaped opening of the thick-walled pipe deformation dead zone and its springback on the welding while the deformation dead zone still exists, realize the parallel butt joint of the welds, and ensure the forming of the thick-walled pipe from the deformation process. quality.

For the directly forming to square pipe mill, four solutions are proposed for the forming difficulties of thick-walled pipes. According to the actual situation, the corresponding solutions are used to solve them. I hope to provide you with effective help.

Part of the content of this site comes from the Internet. This site only provides information storage. The copyright belongs to the original author. It does not bear the relevant legal responsibility and does not represent the views and positions of this site. Please contact and delete it if there is any infringement.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province