Prerequisites for Straightening Welded Pipes by high frequency welded pipe equipment

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-04 11:30

- Pvs:

【概要描述】If the welded pipe is not straight, first check the high frequency welded pipe equipment to see if the problem lies in the sizing. Because it is a very important point to affect the straightness of the welded pipe.

Prerequisites for Straightening Welded Pipes by high frequency welded pipe equipment

【概要描述】If the welded pipe is not straight, first check the high frequency welded pipe equipment to see if the problem lies in the sizing. Because it is a very important point to affect the straightness of the welded pipe.

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-04 11:30

- Pvs:

If the welded pipe is not straight, first check the high frequency welded pipe equipment to see if the problem lies in the sizing. Because it is a very important point to affect the straightness of the welded pipe.

Prerequisites for straightening: From the production practice of high frequency welded pipe equipment, sometimes the straightening head can not be straightened at all, and sometimes it is straightened after a little adjustment, indicating that there are prerequisites for smooth straightening.

Straightening prerequisites:

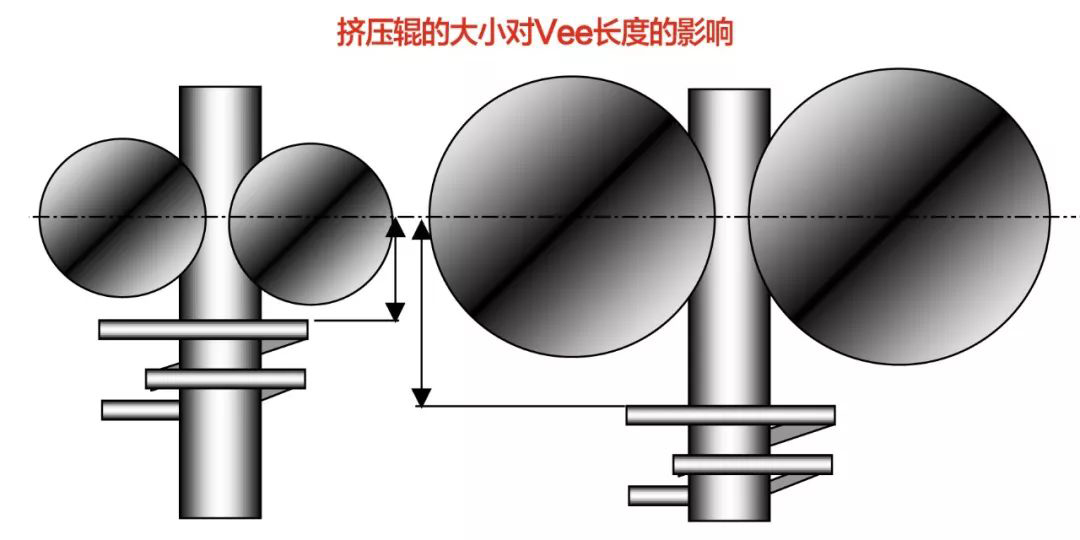

(1) The sizing machine must be used. The sizing machine actually provides two fixed fulcrums (for the two and four-roll straightening heads) for straightening, which cooperate with the movable fulcrum of the straightening head to form two The same direction force application point and an opposite force application point act together on the tube body to complete the straightening. So either two rolls. Either four-roll or eight-roll must be done with the help of a sizing machine.

Another implication of adjusting with the sizing machine is that the magnitude and direction of the straightening force (forming rolling force) provided by the sizing machine must be stable. This is also the reason why once the sizing machine is unstable, the straightness of the welded pipe will bend and sway.

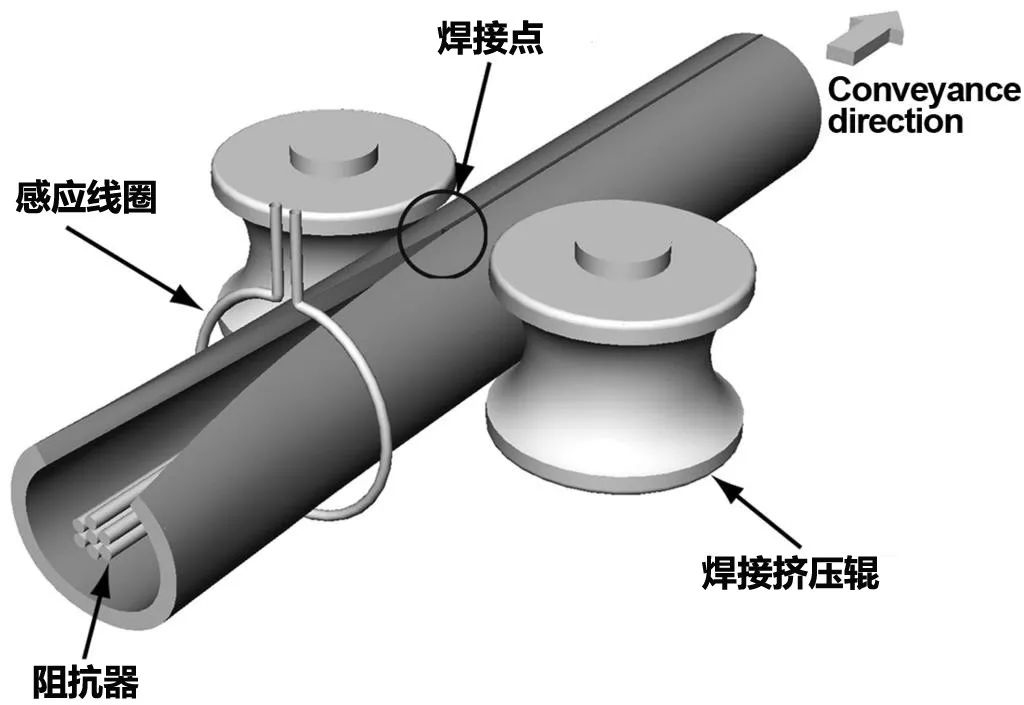

(2)The stress size and direction distribution on the welded pipe in the sizing machine must be stable. The reason why the welded pipe can be straightened is the result of a short-term dynamic balance between the magnitude and direction of the straightening force exerted by the straightening head and the internal stress of the welded pipe in the sizing machine. Flow change, welding heat (high frequency power) change, roll bearing damage and other., will make the originally straight welded pipe bend immediately. It is necessary to change the magnitude and direction of the force applied to the welded pipe through the straightening head to regain the balance. Restore straightness.

(3) The position of the weld seam should be kept stable in the sizing machine. According to the welding principle and welding process, there is a welding heat affected zone at both ends of the weld. Since this area absorbs a lot of heat energy during the welding process of the pipe, the heat affected zone will inevitably accumulate a large amount of shrinkage stress (compressive stress) during the rapid cooling process with the welded pipe (after the extrusion point). The directional stress forces the pipe to be sized to bend to the side of the weld; if the weld deflects, the straightening force, which is just right in force and direction, is applied to the point where the force is not needed (maybe not so much, or it may not be this In this way, the previous stress balance is broken, and the welded pipe changes from straight to curved; before the straightening head does not find a new balance point (manual intervention), the welded pipe has been in a bending state. If the position of the weld is always unstable, the straightening head needs to constantly find a new balance point, and the welded pipe is constantly changing between bend and straight. Therefore, in order to have a good straightness of the welded pipe, the position of the weld must be "fixed" first.

Therefore, if the welded pipe is not straight, it is necessary to check whether there is a problem with the sizing of the high frequency welded pipe equipment, and then do the straightening work from the sizing to straighten the welded pipe to solve the problem of straightening the welded pipe.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province