Methods to prevent the formation of nodules during the production of welded pipes by used HFW pipe units

- Sort:Information

- Auth:

- Source:

- Release time:2022-03-21 11:30

- Pvs:

【概要描述】During the startup and operation of the used HFW pipe units production line, it is impossible to "open the skylight" at the position of the burr knife or the knife bar in the welded pipe to check the accumulation, but the inner burr can be judged from the inner burr pulled out after the flying saw. The scraping condition of the bayonet to determine whether there is accumulation.

Methods to prevent the formation of nodules during the production of welded pipes by used HFW pipe units

【概要描述】During the startup and operation of the used HFW pipe units production line, it is impossible to "open the skylight" at the position of the burr knife or the knife bar in the welded pipe to check the accumulation, but the inner burr can be judged from the inner burr pulled out after the flying saw. The scraping condition of the bayonet to determine whether there is accumulation.

- Sort:Information

- Auth:

- Source:

- Release time:2022-03-21 11:30

- Pvs:

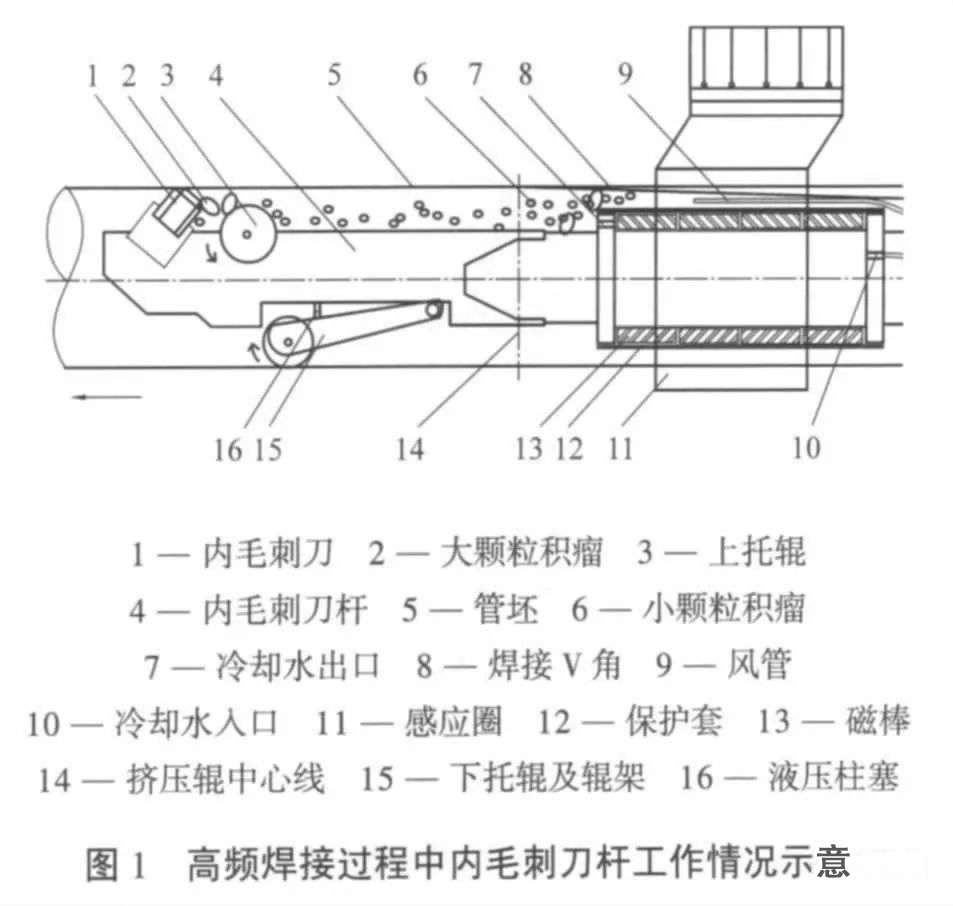

During the startup and operation of the used HFW pipe units production line, it is impossible to "open the skylight" at the position of the burr knife or the knife bar in the welded pipe to check the accumulation, but the inner burr can be judged from the inner burr pulled out after the flying saw. The scraping condition of the bayonet to determine whether there is accumulation.

If there is often a buildup on the inner burr, it means that the high-frequency extrusion welding parameters are not properly set. If the used HFW pipe units is still powered on continuously under this condition, the knife sticking phenomenon is very likely to occur, resulting in large particle accumulation. If the build-up is small and the build-up can smoothly pass through the circular hole of the inner burr knife, it will be clearly visible on the inner burr after cutting by the flying saw; if the build-up is larger and the build-up cannot pass through The circular hole of the inner burr knife accumulates in and near the inner burr knife, which seriously affects the scraping of the inner burr, and even causes the production line to stop passively. Therefore, once there is a buildup on the inner burr after the flying saw is cut, attention should be paid to check whether the high-frequency welding power and the cooling air pressure on the inner burr blade are abnormal.

How to prevent the formation of nodules when the used HFW pipe units produces welded pipes

Methods to prevent small particle accumulation:

The generation of small particle buildup is mainly caused by the inability to remove the particles after the cooling of the splashed spark during the welding process of the used HFW pipe units. Therefore, to prevent the formation of small particles, the main thing is to check whether the air path and water path of the inner burr knife are normal, whether the pressure of the air pressure gauge and water pressure gauge is normal, and check whether the pipeline and pipe head are blocked before starting the machine; At the same time, check whether the upper and lower idlers of the inner burr knife are running normally.

Methods to prevent large particle buildup:

The direct cause of the formation of large particle buildup is that the soldering temperature is too high. The reason why the welding temperature is too high is, on the one hand, due to the unreasonable process parameters, but in most cases, the welding power is increased due to the abnormal butt joint state of the edge of the plate, so that the entire welding seam can reach the welding temperature. Therefore, it should be adjusted by forming to ensure that the butt joint state of the two plates is I-shaped to reduce the probability of large particle accumulation.

There are many factors that cause the accumulation of internal burrs during welding, such as welding parameters, cooling air, cooling water, plate edge quality, upper and lower idlers, straightness of the knife bar, and the quality of the knife. Only by fully understanding the various influencing factors and always paying attention to the external performance of various factors, can the used HFW pipe units and process parameters be adjusted in time, thereby reducing the generation of welding deposits, ensuring the quality of internal burr scraping and Efficient operation of the production line.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province