Key technology of precision welded pipe production by used welded pipe machine—Equipment requirements for butt welded pipe unit

- Sort:Information

- Auth:

- Source:

- Release time:2022-11-08 11:30

- Pvs:

【概要描述】Used welded pipe machine often consider many key technologies when producing precision welded pipes, such as ① quality requirements for raw materials, ② welded pipe forming process, ③ formation and removal of weld burrs, ④ weld heat treatment, ⑤ non-destructive testing, ⑥ correct Equipment requirements for welded pipe unit. For this reason, we introduce the ② welded pipe forming process to be considered in the production of precision welded pipes.

Key technology of precision welded pipe production by used welded pipe machine—Equipment requirements for butt welded pipe unit

【概要描述】Used welded pipe machine often consider many key technologies when producing precision welded pipes, such as ① quality requirements for raw materials, ② welded pipe forming process, ③ formation and removal of weld burrs, ④ weld heat treatment, ⑤ non-destructive testing, ⑥ correct Equipment requirements for welded pipe unit. For this reason, we introduce the ② welded pipe forming process to be considered in the production of precision welded pipes.

- Sort:Information

- Auth:

- Source:

- Release time:2022-11-08 11:30

- Pvs:

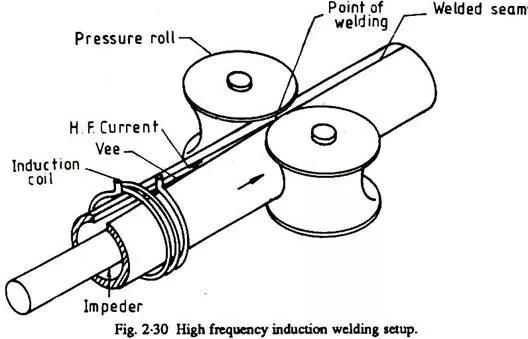

Used welded pipe machine often consider many key technologies when producing precision welded pipes, such as ① quality requirements for raw materials, ② welded pipe forming process, ③ formation and removal of weld burrs, ④ weld heat treatment, ⑤ non-destructive testing, ⑥ correct Equipment requirements for welded pipe unit. For this reason, we introduce the ② welded pipe forming process to be considered in the production of precision welded pipes.

Precision welded pipes are more accurate in geometric dimensions than general welded pipes. The welds and inner and outer surfaces are of good quality, and the wall thickness is uniform. It can be used in equipment components directly or with a small amount of processing. It is widely used in chemical, textile machinery, aviation, instrumentation, automotive and other sectors.

Manufacture of precision welded steel pipes has the characteristics of more precise geometric dimensions than general welded steel pipes, good quality of welds and internal and external surfaces, and uniform wall thickness. Therefore, in the production of precision welded steel pipes, there are the following requirements for the selection of used welded pipe machine and their supporting equipment:

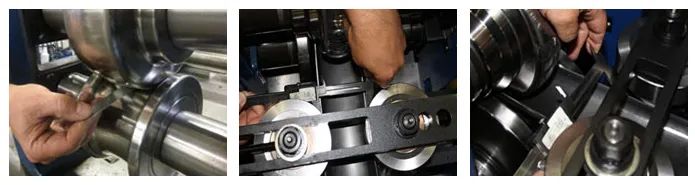

1. High-rigidity and high-strength forming and sizing frame: In order to reduce the strong plastic deformation of the welded pipe unit during maximum load operation, the total accumulated error and elastic deformation of each frame are reduced, so as to improve the dimensional accuracy of precision welded pipes . Therefore, it is necessary to improve the rigidity, strength and machining accuracy of the frame, flat roller shaft, bearing seat, press-up and press-up machinery. When selecting the used welded pipe machine, it is necessary to choose a heavy-duty configuration welded pipe unit and its supporting facilities.

2. Increase the molding machine base 2~3: In order to reduce the elastic deformation, the processing pass should be increased accordingly. Generally, the forming and deformation processing passes of the precision welded pipe unit are increased by 2 to 3 passes than the ordinary welded pipe unit, so the forming machine base needs to be increased by 2 to 3 bases.

3. In order to ensure the uniformity of the rolling centerline (vertical centerline) of each stand, the base shaft should be made in the center, and the positioning dimensions on both sides and the middle sleeve should be accurate. The crew must have precise positioning benchmarks. At the position of the horizontal line, an uphill line (downhill line) or a straight line should be formed in accordance with the process requirements to ensure that no curve fluctuations occur. Therefore, the machine base needs to be equipped with pressing and pressing machinery for easy adjustment.

4. The roll mold has high requirements for strength, toughness, wear resistance, surface finish, dimensional accuracy, hardness, etc. and the hardness must be uniform.

5. Used welded pipe machine should be equipped with lubricant circulation devices to cool and lubricate the rolls to reduce the surface stress on the roll deformed steel strip, prevent surface scratches, and reduce micro-cracks.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province