Key points and reasons for solving welding quality of used welded pipe machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-14 11:30

- Pvs:

【概要描述】There are many factors that affect the welding quality of used welded pipe machine, and these factors interact and restrict each other in the same system.

Key points and reasons for solving welding quality of used welded pipe machine

【概要描述】There are many factors that affect the welding quality of used welded pipe machine, and these factors interact and restrict each other in the same system.

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-14 11:30

- Pvs:

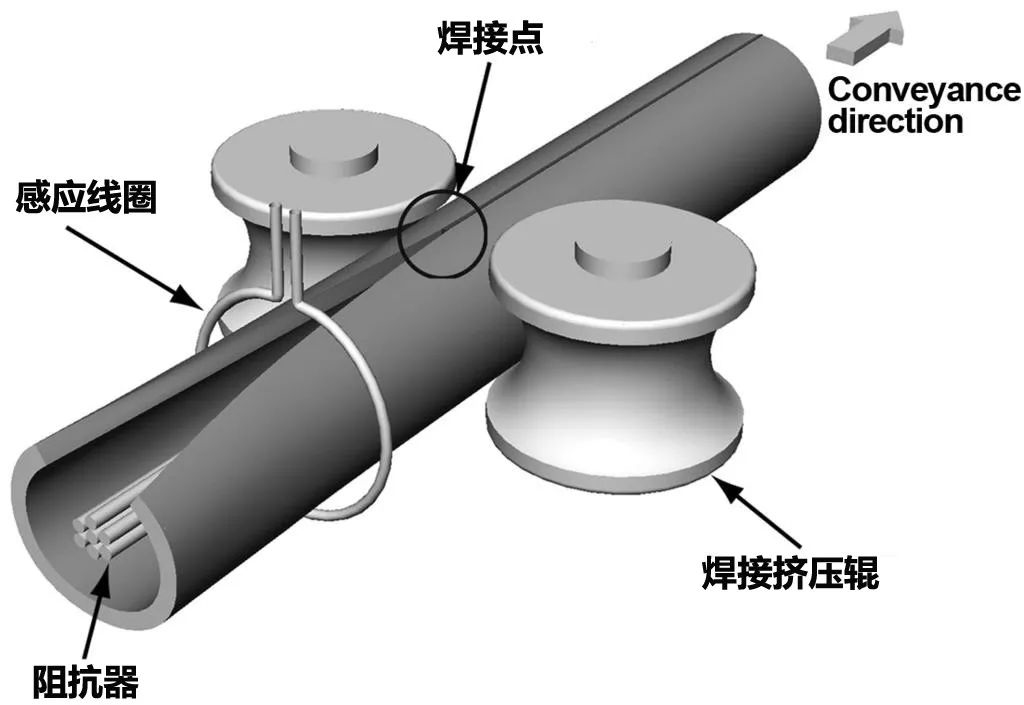

There are many factors that affect the welding quality of used welded pipe machine, and these factors interact and restrict each other in the same system.

When one factor changes, other factors will also change as it changes. Therefore, in high-frequency adjustment, it is not enough to pay attention to the local adjustment of the frequency, power, current or extrusion amount of the used welded pipe machine. This adjustment must be based on the specific conditions of the entire forming system. All aspects related to frequency welding are considered comprehensively, and all influencing factors are eliminated one by one to adjust.

Below we break down the main factors in the high-frequency welding process. According to eight aspects, we will introduce in detail the common problems and their causes/solutions of high-frequency welding of used round tube forming machines.

①Weak welding, desoldering, cold folding;

Reason: The output power and squeezing force are too small.

Solution: 1. adjust the power of the high-frequency welder; 2. change the groove shape of the thick tube blank; 3. adjust the extrusion force

②There are ripples on both sides of the weld;

Reason: the rendezvous angle is too large

Solution: 1. adjust the position of the guide roller; 2. adjust the solid bending section; 3. increase the welding speed

③There are deep pits and pinholes in the weld;

Reason: Overburn

Solution: 1. Adjust the position of the guide roller and increase the closing angle; 2. Adjust the power; 3. Increase the welding speed

④Weld burrs are too high;

Reason: The heat-affected zone is too wide

Solution: 1. increase the welding speed; 2. adjust the power;

⑤Slag inclusion;

Reason: the input power is too large and the welding speed is too slow

Solution: 1. Adjust the power; 2. Increase the welding speed

⑥External cracks in the weld;

Reason: The quality of the base metal is not good; it is subjected to too much squeezing force

Solution: 1. to ensure the quality of raw materials; 2. to adjust the extrusion force

⑦Wrong welding, lap welding;

Reason: Poor molding accuracy

Solution: Adjust the forming die roll of the unit

The key process of the used welded pipe machine in the production of welded pipes during high-frequency welding. Due to the systematic influencing factors and the mutual constraints of these factors, we still need to explore the experience in the first line of production.Each unit has its own design and manufacturing differences, and each operator has different habits.

We provide these materials to everyone in order to allow us to better understand the basic principles of high-frequency welding, so as to better combine our own production practices and summarize the operating procedures suitable for our own units.

At the same time, the welded pipe equipment industry is also developing with each passing day. More equipment manufacturers are investing in R&D and experimentation for automation and standardization. It is expected that welded pipe production equipment can do so in the near future.

According to the specifications and usage of the product, it can be adjusted automatically.

Therefore, to fully understand the common problems of high-frequency welding of used welded pipe machine and their causes/solutions, it is necessary to analyze other aspects of the main points of welding quality of used welded pipe machine in order to summarize the methods. Those in need can continue to pay attention to us.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province