Introduction to the welding process of high frequency welded pipe machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-06 11:30

- Pvs:

【概要描述】We usually want to know the basic information of the high frequency welded pipe machine, which is to know the size and production speed of this unit suitable for the production of pipes through the welding pipe-making process.

Introduction to the welding process of high frequency welded pipe machine

【概要描述】We usually want to know the basic information of the high frequency welded pipe machine, which is to know the size and production speed of this unit suitable for the production of pipes through the welding pipe-making process.

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-06 11:30

- Pvs:

We usually want to know the basic information of the high frequency welded pipe machine, which is to know the size and production speed of this unit suitable for the production of pipes through the welding pipe-making process.

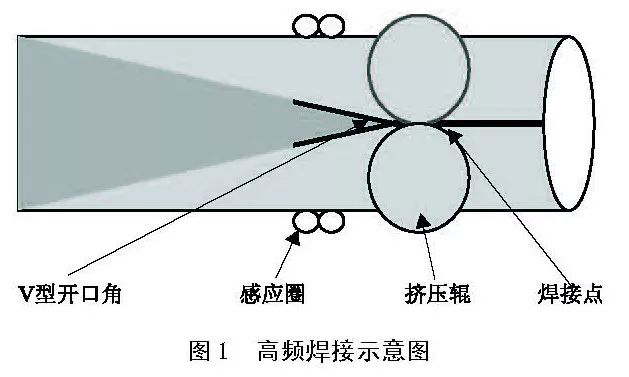

Generally, the high-frequency welded pipe is fed into the forming machine through the steel strip, and the cylindrical tube blank is formed through the induction coil (Figure 1)

The magnetic field near the induction coil generates an induced current that passes through the edge of the steel strip, and the edge of the steel strip is heated due to resistance heat generated by its own resistance. High-frequency welding has no added amount and is actually a forge welding. If the production process of the high frequency welded pipe machine is well controlled, there will be no residual molten metal or oxide on the fusion surface.

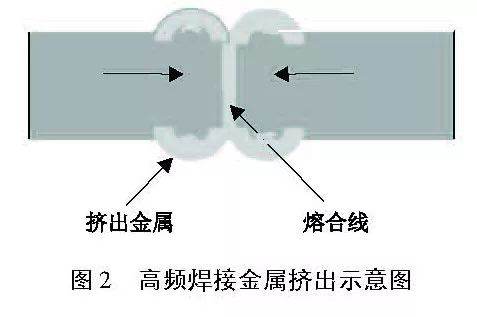

Figure 2 shows the situation where the liquid metal or oxide is squeezed out of the weld when the edge of the steel strip passes through the squeeze rollers.

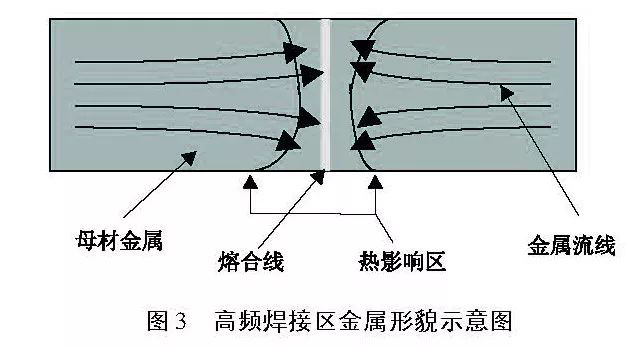

If a weld sample is cut for polishing and corrosion and observed under a metallographic low-magnification microscope, the morphology of the normal high-frequency welding area is shown in Figure 3, and the heat-affected zone is shaped like a waist drum.

This is the heat generated by the high frequency welded pipe machine due to the entry of high-frequency current from the end and edge of the steel strip edge. The heat-affected zone is slightly darker than the base metal because carbon diffuses toward the edge of the heated strip during welding and is absorbed at the edge of the strip as the weld cools. Especially the carbon near the edge is oxidized to CO or CO2, and the remaining iron has no carbon and becomes lighter in color.

The metal flow lines seen on the metallographic specimens are actually the high carbon areas rolled into flat, discontinuous planes when the billet is rolled into strip. The size of the rise angle of the metal streamline is often used to evaluate the degree of upsetting during welding.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province