Influence of welding process on welding quality of cold roll forming machine

- Sort:Information

- Auth:

- Source:

- Release time:2023-03-18 11:30

- Pvs:

【概要描述】Whether the welding quality of the cold roll forming machine meets the standard depends on the welding process. The welding process generally affects the quality of the welded pipe. The following describes the influence of the welding process on the welding quality of the cold bending forming machine.

Influence of welding process on welding quality of cold roll forming machine

【概要描述】Whether the welding quality of the cold roll forming machine meets the standard depends on the welding process. The welding process generally affects the quality of the welded pipe. The following describes the influence of the welding process on the welding quality of the cold bending forming machine.

- Sort:Information

- Auth:

- Source:

- Release time:2023-03-18 11:30

- Pvs:

Whether the welding quality of the cold roll forming machine meets the standard depends on the welding process. The welding process generally affects the quality of the welded pipe. The following describes the influence of the welding process on the welding quality of the cold bending forming machine.

The influence of the welding process on the welding quality of the cold roll forming machine can be divided into: ①V-shaped angle; ②Welding temperature; ③Welding extrusion force (extrusion amount); ④Welding speed; ⑤Steel strip edge condition.

(1) Influence of V-shaped angle on welding quality

1. Convergence point and welding point

①The meeting point should be as close to the welding point as possible, that is, the position of the V-shaped angle should be as close as possible to the center line of the squeeze roller (the joint position of the squeeze roller)

② Since there is no current passing through the area between the junction and the centerline of the squeeze roll, the edge of the steel strip in this area is not further heated, in order to keep the temperature of the weld zone high enough during the application of the squeezing force to form a good the weld, the confluence point should be as close as possible to the centerline of the squeeze roll

2. V-shaped corner opening angle

Keeping the meeting point as close as possible to the centerline of the squeeze rolls also means that the opening angle should be as large as possible.

①Reducing the opening angle can enhance the proximity effect of the current and improve the welding efficiency, but if the opening angle is too small, the distance from the confluence point to the center line of the extrusion roller will be lengthened, so that the strip edge is not extruded at the highest temperature. , which reduces the welding quality. In addition, when the opening angle is too small, after the liquid lintel is formed, under the action of the magnetic force line, it moves to the welding point and gathers into a larger lintel, which forms deep pits and pinholes that are difficult to press after blasting.

② When the opening angle is too large, the melting section becomes shorter and the flashing is stable, but the proximity effect of the current is weakened, the welding efficiency is obviously reduced, and the power consumption is increased. Creates wavy folds.

③ Therefore, the opening angle of the cold roll forming machine is generally controlled at 3°~6° in practical production.

3. V-shaped corner length

①In actual production, the distance between the induction coil and the center line of the squeeze roller should be shortened as much as possible. That is, the length of the V-shaped angle. If the distance is too long, the effective heating time will increase, and the heat affected zone will be widened, thereby reducing the strength of the weld and the stability of the weld.

② However, in the production of thick-walled welded pipes, the position of the induction coil should be appropriately moved to the direction of the forming unit, the length of the V-shaped angle should be increased, the heating time will be longer, and the opening angle of the V-shaped angle should be appropriately reduced to enhance the current proximity effect. Improve the heating efficiency, reduce the temperature difference between the inner and outer walls of the tube blank, effectively control the dripping phenomenon, and at the same time appropriately increase the extrusion force to effectively prevent reflow inclusions to ensure welding quality.

(2) Influence of welding temperature on welding quality

①Because the welding temperature is difficult to measure, the welding power is usually used to control the welding temperature.

② When the welding heat is insufficient, the edge of the heated steel strip cannot reach the welding temperature, and the solid structure is still maintained, forming an incomplete cold welding.

③ When the input heat is too large, the edge of the heated steel strip exceeds the welding temperature, which is prone to overheating or even overburning, causing the weld breakdown to cause the fusion metal to splash and form small holes.

④If the temperature is too high, it is easy to cause backflow slag inclusion, which affects the quality of flaw detection.

(3) Influence of welding extrusion force (extrusion amount) on welding quality

①After the two edges of the joint of the tube blank are heated to the welding temperature, under the extrusion of the extrusion roller, the metal grains are combined to form a welding seam.

②If the extrusion force is small, the number of bonds between grains will be small, the strength of the weld will be reduced, and cracking will easily occur after being stressed.

③If the extrusion force is too large, all the metal that reaches the welding temperature will be extruded, which will not only reduce the strength of the weld, but also produce welding defects such as excessive internal and external burrs and lap welding.

④ In production practice, it is difficult to measure the size of the extrusion force. Usually, the size of the extrusion force is used to measure the size of the extrusion force. The extrusion amount is usually calculated from the circumference of the tube blank before welding minus the tube with the outer burr removed after welding. body circumference.

⑤In production, different wall thicknesses use different extrusion amounts. The relationship between wall thickness and extrusion amount is shown in Table 1 below.

In the production practice, the production of ordinary carbon steel is more likely to produce inclusions, and it is often necessary to increase the extrusion amount and control the welding temperature to solve the problem.

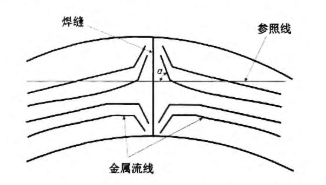

When adjusting the extrusion force, it should be adjusted according to the inspection report of the weld metal flow line. The weld metal flow line is shown in the figure below.

The angle α of the metal streamline should be symmetrical and the size should be appropriate. The detection of the weld metal streamline has important guiding significance for on-site production.

Example: Sampling and analysis of welded pipes with flaw detection defects

The scanning electron microscope photos of the weld inclusions are as follows: the composition analysis is shown in Table 2 below

It can be seen from Table 2 that the weld inclusions are iron oxides.

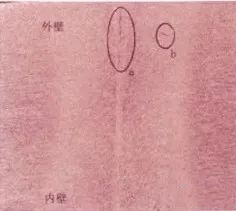

The picture below is a photo of the weld flow line. From the picture, we can also see the cracks left by the weld after the weld inclusions are corroded. The a is the fusion line, and the b is the flow line.

According to the streamline analysis, the difference between the angle between the inner and outer walls is nearly 30°, and the center distance reaches 1.5mm. Obviously, due to the serious imbalance of the extrusion force, the inner wall is too large and the outer wall is too small. The insufficient extrusion force of the outer wall makes some iron oxides The molten material is not completely extruded and stays in the weld, and in severe cases, it will break from the wall thickness direction and cause cracks on the inner or outer wall.

(4) Influence of welding speed on welding quality

①When the welding speed is increased, the formation of oxide inclusions can be reduced, the heat affected zone can be shortened, and the oxide layer can be extruded from the molten groove;

② On the contrary, when the welding speed is very low, the heat-affected zone becomes wider, larger welding burrs will be generated, the oxide layer will be thickened, and the quality of the welding seam will be deteriorated.

③ Generally speaking, the higher the welding speed, the better the welding quality, which can reduce the generation of welding drip. However, for the production of thick-walled pipes, the welding speed should be properly controlled to increase the heating time and ensure the welding heat.

(5) The influence of the edge condition of the steel strip on the welding quality

The edge condition and shape of the strip are also important factors for the quality of high-frequency welding.

If the edge of the steel strip to be welded is uneven or irregular, the welding efficiency will be greatly reduced. Due to uneven or burrs on the edge of the strip, it may cause the welding surface to contact the arc in advance and cause a short circuit. On the one hand, the current density of the first half of the V-shaped angle increases and heats rapidly, and it will be heated and extruded before the weld is formed, consuming a lot of energy; on the other hand, the current density of the second half is greatly reduced. When pressing the roller, the base metal cannot be heated to the welding temperature, which is easy to cause cold welding.

Common defects on the edge of the steel strip include camber, wavy and slitting.

① The camber bending will cause the deviation or reversal of the steel strip, which will cause the welding seam to deviate, and more seriously cause the welding seam to form lap welding, resulting in inconsistency;

②The wave shape will easily cause cracks and cracks during welding;

③ The gnawing edge (that is, the phenomenon that the edge of the steel strip is jagged and uneven) is caused by the dullness of the disc blade of the slitting machine. Cracks or cracks are produced and the quality of the weld is affected.

Therefore, the edges of the tube blank to be welded are as flush as possible, and the I-type welding is maintained, so that the proximity effect and temperature of the inner and outer surfaces tend to be consistent, and the welding quality is improved.

There are many factors that affect the welding quality of cold roll forming machine. According to factors such as material and wall thickness, the welding process parameters are continuously summarized, improved and optimized in production, so as to improve the welding quality.

The quality of products can be guaranteed only when people, machines, materials, methods, and measurements are comprehensively and continuously controlled in the production process of welded pipes.

Part of the content of this site comes from the Internet. This site only provides information storage. The copyright belongs to the original author. It does not bear the relevant legal responsibility and does not represent the views and positions of this site. Please contact and delete it if there is any infringement.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province