Influence of the defects of the welded pipe blank of the high frequency welded pipe machine on the quality of the welded pipe (9)

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-10 11:30

- Pvs:

【概要描述】When using the high frequency welded pipe equipment to manufacture steel pipes, the steel pipe will have common problems of indentation and pits. There are two types of indentation.

Influence of the defects of the welded pipe blank of the high frequency welded pipe machine on the quality of the welded pipe (9)

【概要描述】When using the high frequency welded pipe equipment to manufacture steel pipes, the steel pipe will have common problems of indentation and pits. There are two types of indentation.

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-10 11:30

- Pvs:

When using the high frequency welded pipe equipment to manufacture steel pipes, the steel pipe will have common problems of indentation and pits. There are two types of indentation. One is linear indentation, which is caused by improper roll position adjustment; the other is crescent-shaped indentation, which is caused by protrusions produced after the roll is worn out. The pits of the steel pipe are generally caused by the bumps on the roll and the adhered oxide scale on the roll.

1. Linear indentation

(1) Continuous linear indentation

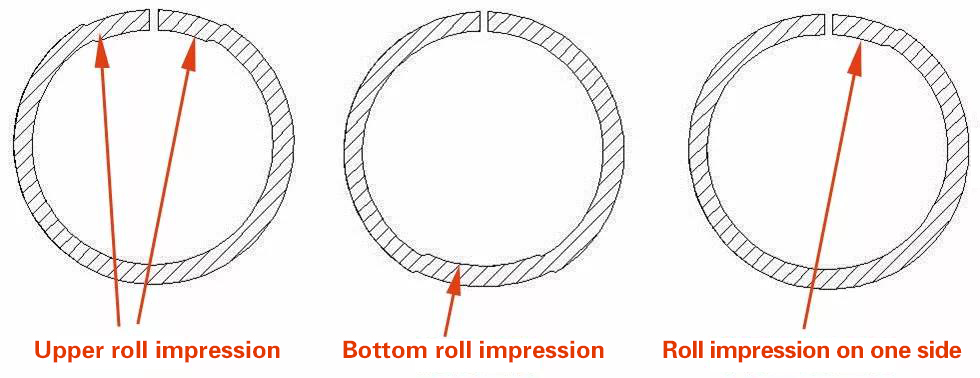

The high frequency welded pipe equipment is caused by the poor roll position between the rollers. It often occurs between the roll gaps. The indentation between the upper roller and the side roller is the most common indentation. In addition, the side roller and the bottom roller may also be Produce indentation. (See below)

Figure 14*1 shows the indentation produced by the welding squeeze upper roller

Reason: Generally, it is caused by improper matching of the side roller and the upper roller.

Adjustment method: You can increase the squeeze upper roller position or reduce the distance between the roller positions on both sides.

Figure 14*2 is the indentation produced by the welding squeeze lower roll

Reason: Generally, it is caused by improper matching of the roller position of the side roller and the lower roller.

Adjustment method: You can reduce the roller position of the lower squeeze roller or reduce the distance between the roller positions on both sides.

Figure 14*3 shows the indentation produced by single-side squeezing the upper roller

Causes and adjustment methods:

A. The height of one of the squeezing upper rollers is too low, adjust the height of the single squeezing upper roller.

B. The squeeze side rollers are asymmetrical. Due to the different forces, the side rollers on the side where the indentation is produced can be tightened, or the side rollers on the side where the indentation is not produced can be relaxed.

C. caused by different heights of side rollers.

D.Improper squeeze upper rollers cause the two squeeze upper rollers to be unequal to the weld seam. Adjust the squeeze upper roller frame horizontally.

(2) Discontinuous linear indentation

Common reasons:

A. Generally, the roller bearing is damaged.

B. On the split roll, the indentation caused by the part of the roll part deviating from the original position due to the partial fracture of the roll screw.

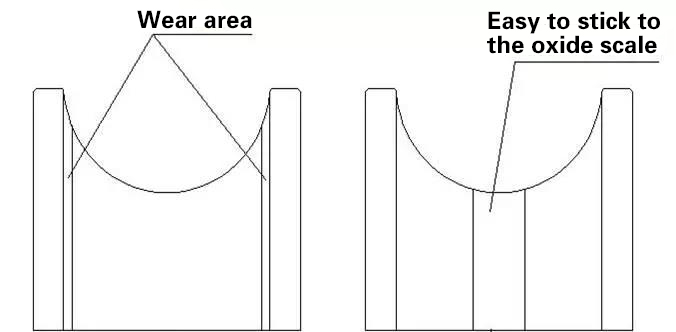

2. Crescent indentation

Generally, the surface of the roll is worn and there are uneven contact surfaces, which cause crescent-shaped indentation on the steel pipe. The crescent-shaped indentation generally appears at the position with the largest radius of the roll. The reason is that the linear speed of the roll is the largest and the friction is the largest (as follows picture). The crescent-shaped indentation produced by the high frequency welded pipe equipment grinder can be removed by grinding with an online grinding wheel.

3. The pit

Reason 1: There are bulges on the rolls, which cause pits on the steel pipe. The cause is the same as the crescent-shaped indentation.

Reason 2: The indentation produced by the sizing upper roller. Due to the large amount of scale produced at the welding seam after intermediate frequency heat treatment, it sticks to the surface of the sizing roll after passing through the sizing roll. In the case of improper emulsion spraying position or small emulsion water flow, the scale is not washed away After long-term operation, the oxide scale will accumulate more and more, which will eventually cause pits near the weld of the welded pipe.

Part of the content of this site comes from the Internet. This site only provides information storage. The copyright belongs to the original author. It does not bear the relevant legal responsibility and does not represent the views and positions of this site. Please contact and delete it if there is any infringement.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province