Influence of annealing temperature on the performance of used welded pipe equipments

- Sort:Information

- Auth:

- Source:

- Release time:2023-01-03 11:30

- Pvs:

【概要描述】We know that the welding process of used welded pipe equipments will cause work hardening and welding stress during the forming and welding process. If the annealing temperature is low, the stress and hardening cannot be fully eliminated, so the strength of the welded pipe after annealing is high but the plasticity is poor. With the increase of the annealing temperature, the stress and hardening are gradually eliminated, so that the strength of the welded pipe is reduced and the plasticity is improved.

Influence of annealing temperature on the performance of used welded pipe equipments

【概要描述】We know that the welding process of used welded pipe equipments will cause work hardening and welding stress during the forming and welding process. If the annealing temperature is low, the stress and hardening cannot be fully eliminated, so the strength of the welded pipe after annealing is high but the plasticity is poor. With the increase of the annealing temperature, the stress and hardening are gradually eliminated, so that the strength of the welded pipe is reduced and the plasticity is improved.

- Sort:Information

- Auth:

- Source:

- Release time:2023-01-03 11:30

- Pvs:

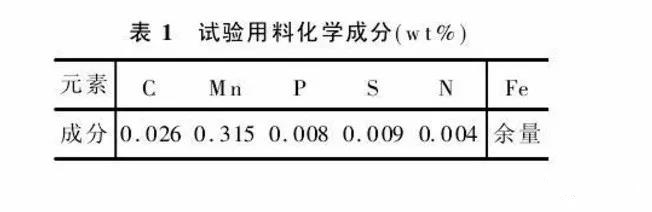

The test material is ST14 cold-rolled strip produced by Baosteel, and the chemical composition is shown in Table 1.

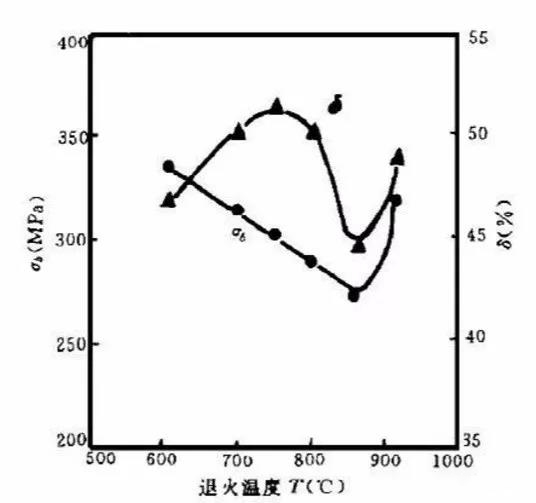

We know that the welding process of used welded pipe equipments will cause work hardening and welding stress during the forming and welding process. If the annealing temperature is low, the stress and hardening cannot be fully eliminated, so the strength of the welded pipe after annealing is high but the plasticity is poor. With the increase of the annealing temperature, the stress and hardening are gradually eliminated, so that the strength of the welded pipe is reduced and the plasticity is improved.

But why does the plasticity start to decrease when the annealing temperature exceeds 800℃? From the iron-carbon phase diagram, we know that in this temperature range, the material is in the two-phase region of ferrite and austenite, and the original structure is partially transformed into austenite, but some ferrite has not been transformed. It can be known from the calculation that about 10% of the cold deformation of the experimental material occurs during the forming of the welded pipe; due to the small degree of cold deformation, the material rarely recrystallizes during annealing. These untransformed ferrites grow up during the annealing process, and the higher the temperature, the coarser the grains, and these coarse ferrite grains remain after annealing and cooling. On the other hand, the austenite formed by heating to a high temperature forms fine ferrite grains after cooling, which in turn causes uneven grain size, thereby reducing both strength and plasticity.

When the annealing temperature is 920℃, the welded pipe has good strength and plasticity at the same time. During the welding process of used welded pipe equipments, not only a small amount of unbalanced weld structure such as martensite is formed in the weld, but also the grains in the heat-affected zone are coarse, which all have an adverse effect on the performance. Only by heating to a temperature above Ac3 to make the structure all austenitic can these effects be eliminated, so that the structure of the weld and the base metal tends to be consistent, that is, a fine structure is obtained, thereby improving the mechanical properties of the welded pipe.

Problems that should be paid attention to in production

If the user requires the welded pipe to have good plasticity, but does not require too high strength, we can use the temperature between 700 ~ 800℃ for continuous annealing. In this case, the temperature range is wide, and it is easy to control the production process. .

If the user requires the welded pipe to have high strength and good plasticity at the same time, then annealing between 700 and 800℃ cannot meet the requirements. Because in the high-frequency welding process, due to the combined effect of skin effect, proximity effect and heat conduction, the peak temperature of welding thermal cycle is distributed in gradient at the opening edge of the tube blank, and melting zone, partial melting zone and overheating structure zone appear. feature area. Therefore, the unbalanced structure and coarse structure around the weld have adverse effects on the performance of the welded pipe; to eliminate these effects, the heat treatment temperature must be increased to above Ac3. But the temperature should not be too high, otherwise the performance will deteriorate.

This requires that the annealing temperature be strictly controlled in the actual production process of used welded pipe equipments, so that the annealing temperature is guaranteed to be around 920℃. On the other hand, fast cooling is required in the initial stage of cooling, which requires the circulating water to have sufficient cooling capacity to ensure a uniform and refined structure after heat treatment, thereby ensuring the quality of the product.

The experiment was carried out in a continuous annealing furnace, and the experimental results are shown in the figure below. It can be seen that when the annealing temperature is low, the strength of the sample is high, but the plasticity is poor. With the increase of annealing temperature, the tensile strength decreased gradually and the elongation increased continuously, which was mainly because the stress and hardening in the welded pipe were gradually eliminated during the annealing process. But after the annealing temperature exceeds 800℃, not only the strength continues to decrease, but also the elongation begins to decrease.

In conclusion

When the used welded pipe equipments are used to make pipes, if the welded pipe is required to have good plasticity and general strength, the temperature between 700 and 800℃ can be used. However, when the welded pipe is required to have high strength and good plasticity at the same time, it is recommended to use a temperature of 920℃ and make the water temperature of the cooling water tank lower to ensure a certain cooling rate.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province