Improving lubricating effect of flying saw on used welded pipe equipment

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-16 11:30

- Pvs:

【概要描述】Through the technical improvement of the used welded pipe equipment, the lubrication of the gear and rack of the flying saw has been effectively improved, and the specific performance is as follows:

Improving lubricating effect of flying saw on used welded pipe equipment

【概要描述】Through the technical improvement of the used welded pipe equipment, the lubrication of the gear and rack of the flying saw has been effectively improved, and the specific performance is as follows:

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-16 11:30

- Pvs:

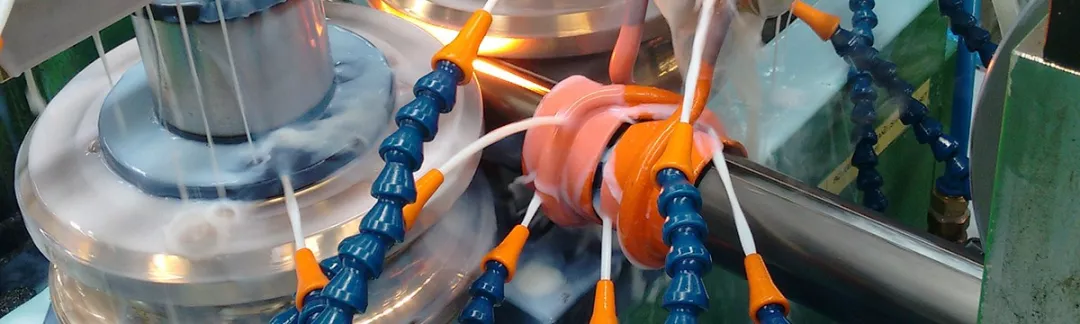

Through the technical improvement of the used welded pipe equipment, the lubrication of the gear and rack of the flying saw has been effectively improved, and the specific performance is as follows:

(1) The lubricating oil plays a cooling role of heat absorption, heat transfer and heat dissipation, which can effectively cool the gear and rack and avoid high temperature;

(2) When the lubricating oil flows between the friction surfaces, the solid particles on the surface of the gear and rack can be washed away to keep the friction surface smooth;

(3) The lubricant forms a seal with the contact surface, preventing the entry of water and solid dust, and ensuring the cleanliness of the contact surface;

(4) The oil layer can convert the mechanical energy generated by shock and vibration into hydraulic energy, which can buffer and shockproof and reduce noise;

(5) The applied load can evenly act on the friction surface through the oil film. Even when dry friction occurs locally, the remaining oil film can still bear the rest of the load, which can greatly reduce the load acting on the friction point;

(6) The oil layer can protect the metal surfaces of gears and racks to a certain extent and prevent corrosion.

Through the technical improvement of the used welded pipe equipment, the gears and racks of the flying saw saw are effectively lubricated, which reduces the wear of the equipment, prolongs the service life of the equipment, reduces the friction factor between the two, and reduces the Frictional resistance, surface wear and energy loss make the reciprocating motion of the saw car run more smoothly, thereby improving production efficiency.

Through the technical improvement of the used welded pipe equipment, the lubrication of the gears and racks of the flying saw has been effectively improved, and the gears and racks have not been replaced every year. The saw car was hoisted up, and after checking the gear and rack with the inspection disc, it was found that the wear amount was still within the allowable range of gear accuracy, and it could continue to be used. It can be proved that the technical improvement proposed by the author is reasonable through the use of flying saws in production practice, and it can provide sufficient lubrication for gears and racks.

This technical improvement of the used welded pipe equipment strengthens the lubrication of the gears and racks of the flying saw, which not only reduces the wear of the equipment and prolongs the service life of the equipment, but also reduces the manual workload and reduces the production cost. Improve production efficiency and avoid oil pollution to the environment.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province