How to maintain and maintain the cold forming machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-08-21 11:30

- Pvs:

【概要描述】In the production process of cold roll forming machine, damage problems usually occur early. Everyone must pay attention to the repair and maintenance of cold roll forming machine in order to maintain the stable development trend of the production process. The following is an explanation of the repair and maintenance methods of the cold roll forming machine.

How to maintain and maintain the cold forming machine

【概要描述】In the production process of cold roll forming machine, damage problems usually occur early. Everyone must pay attention to the repair and maintenance of cold roll forming machine in order to maintain the stable development trend of the production process. The following is an explanation of the repair and maintenance methods of the cold roll forming machine.

- Sort:Information

- Auth:

- Source:

- Release time:2022-08-21 11:30

- Pvs:

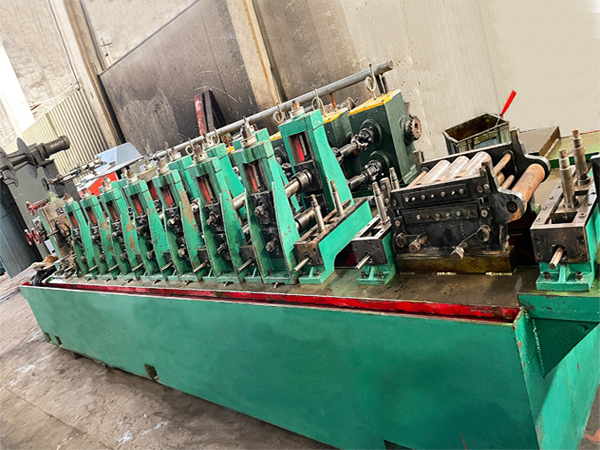

In the production process of cold roll forming machine, damage problems usually occur early. Everyone must pay attention to the repair and maintenance of cold roll forming machine in order to maintain the stable development trend of the production process. The following is an explanation of the repair and maintenance methods of the cold roll forming machine.

1. In the whole process of application, everyone must follow the operating steps in the manual to strictly perform the actual operation, not to mention the overloaded operation and application of the cold roll forming machine, and the operation of the cold roll forming machine Before, it is necessary to check whether each part of the equipment is working properly and whether there are any common faults. Only when the various parts and index values of the cold roll forming machine are all normal, it can be started up. Put into production, otherwise it will lead to the loss of equipment.

2. After inspecting each part of the cold roll forming machine, we start it up again. During the production process of the cold roll forming machine, we must ensure that the temperature of the equipment and the stability of its production and manufacturing conditions, if common failures occur in the equipment It is necessary to immediately terminate its production and check which component of the equipment has a problem to prevent greater losses. The key common faults include the unstable operation of the equipment, the grinding and polishing of the equipment, and whether there is abnormal noise during the whole operation. If a problem occurs, it should be checked immediately.

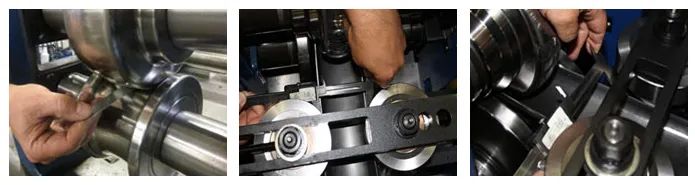

3. After the cold roll forming machine has been used for a period of time, everyone needs to pay attention to the regular lubrication and cleaning of the equipment to ensure that the cold roll forming machine is clean and tidy. The process is relatively light, and the aging parts in the equipment must be replaced immediately to ensure that the equipment can operate normally anytime and anywhere. In addition, if the equipment is not applicable, the cold roll forming machine should be kept well, and it should not be thrown away at will.

The above is the repair and maintenance of the cold roll forming machine, I hope to have some assistance to you. Our company has many brands and resources, and there is always one that suits you. You only need to inform us of your pipe-making needs, and our company will provide you with used welded pipe equipment that truly suits your needs. Welcome new and old customers to consult and order.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province