How to correctly choose the induction coil of high frequency welded pipe equipment

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-14 11:30

- Pvs:

【概要描述】Correct selection of induction coils is important for maximum welding efficiency The process parameters of high frequency welded pipe equipment production include welding speed (unit speed), welding temperature (high-frequency power), welding current (high-frequency frequency), extrusion force (die design and material), opening V angle, inductor (material of the coil, winding direction, position) and size and position of the resistor (bar magnet).

How to correctly choose the induction coil of high frequency welded pipe equipment

【概要描述】Correct selection of induction coils is important for maximum welding efficiency

The process parameters of high frequency welded pipe equipment production include welding speed (unit speed), welding temperature (high-frequency power), welding current (high-frequency frequency), extrusion force (die design and material), opening V angle, inductor (material of the coil, winding direction, position) and size and position of the resistor (bar magnet).

- Sort:Information

- Auth:

- Source:

- Release time:2022-07-14 11:30

- Pvs:

Correct selection of induction coils is important for maximum welding efficiency

The process parameters of high frequency welded pipe equipment production include welding speed (unit speed), welding temperature (high-frequency power), welding current (high-frequency frequency), extrusion force (die design and material), opening V angle, inductor (material of the coil, winding direction, position) and size and position of the resistor (bar magnet).

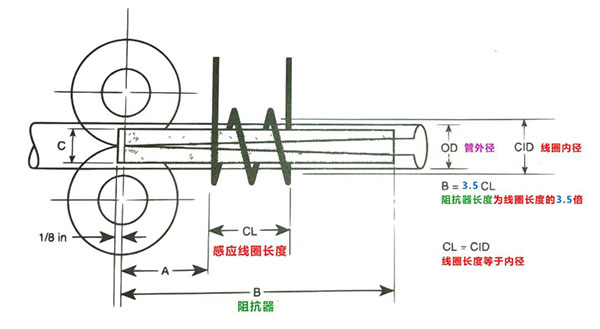

The distance A between the coil and the squeeze roll depends on the design of the rolling mill and the diameter of the squeeze roll. The smaller the A, the better, and it is best not to exceed the diameter of the tube, as shown in the figure above.

The inner diameter of the coil and its length should be equal and about 20% larger than the pipe diameter

High frequency (steady and continuous) power, welding speed, welding extrusion force and opening V angle are the most important process parameters, which must be reasonably matched, otherwise the welding quality will be affected.

If the speed is too high or too low, it will cause low temperature weld impermeability and high temperature overburning, and the weld will crack after flattening.

When the extrusion force of the high frequency welded pipe equipment is insufficient, the edge metals to be welded cannot be completely pressed together, the residual impurities in the weld are not easily discharged, and the strength is reduced. When the extrusion force is too large, the metal flow angle increases, the residue is easily discharged, the heat affected zone is narrowed, and the welding quality is improved. However, if the pressure is too high, it will cause large sparks and spatters, causing the molten oxide and part of the metal-plastic layer to be squeezed out, and the weld will become thinner after being scratched, thereby reducing the strength of the weld. Appropriate extrusion force is an important prerequisite for ensuring welding quality.

The opening angle is too large, which reduces the high frequency proximity effect, increases the power loss, and reduces the soldering temperature. If the welding speed is constant, there will be no penetration; if the opening angle is too small, the welding current will be unstable and a small spatter will occur at the pinch point.

The induction coil is an important part of the production of high frequency welded pipe equipment, and the gap between it and the pipe blank and the width of the opening have a great impact on the welding quality.

The gap between the induction coil and the tube blank is too large, resulting in a sharp drop in the inductance efficiency;

If the gap between the induction coil and the tube blank is too small, it is easy to generate electric discharge between the coil and the tube blank, and it is also easy to be damaged by the moving tube blank.

If the width of the induction coil is too large, the welding temperature of the butt edge of the tube blank will be reduced. If the welding speed is fast, false welding and cracking are likely to occur after straightening.

Our company has many brands and wide resources, there is always one suitable for you. You only need to inform us of your pipe manufacturing needs, and our company will provide you with used welded pipe equipment that really suits your needs. Welcome new and old customers to come to consult and order.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province