How to adjust the welding process parameters of high frequency welded pipe machine(3)

- Sort:Information

- Auth:

- Source:

- Release time:2022-08-09 11:30

- Pvs:

【概要描述】There are many factors that affect the welding process of high frequency welded pipe machine: squeeze rollers, welded pipe materials, welding power, welding frequency elements and welding speed elements. From these elements, we can analyze the actual impact on welding, and we can conclude The purpose of the welding process is mainly to control two contents: the size of the heat-affected zone (the volume of the heated material in the extrusion zone) and the heating time of the heat-affected zone.

How to adjust the welding process parameters of high frequency welded pipe machine(3)

【概要描述】There are many factors that affect the welding process of high frequency welded pipe machine: squeeze rollers, welded pipe materials, welding power, welding frequency elements and welding speed elements. From these elements, we can analyze the actual impact on welding, and we can conclude The purpose of the welding process is mainly to control two contents: the size of the heat-affected zone (the volume of the heated material in the extrusion zone) and the heating time of the heat-affected zone.

- Sort:Information

- Auth:

- Source:

- Release time:2022-08-09 11:30

- Pvs:

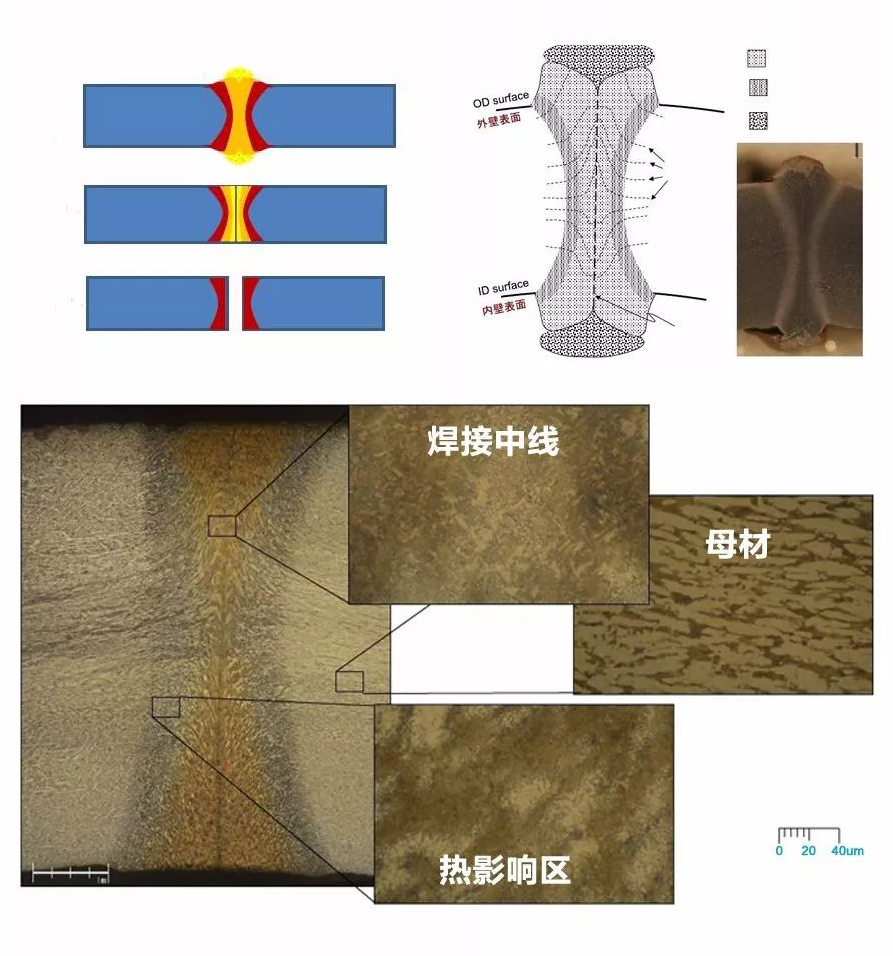

There are many factors that affect the welding process of high frequency welded pipe machine: squeeze rollers, welded pipe materials, welding power, welding frequency elements and welding speed elements. From these elements, we can analyze the actual impact on welding, and we can conclude The purpose of the welding process is mainly to control two contents: the size of the heat-affected zone (the volume of the heated material in the extrusion zone) and the heating time of the heat-affected zone.

① Heat affected zone size

In the process of operating high-frequency welding of high frequency welded pipe machine, the size of the heat-affected zone directly affects the quality of the welded product, which is very important. , the material consumption increases; if the heat affected zone is too small, the weld fusion is insufficient and the welding is unqualified. Only with a suitable heat-affected zone size can a suitable weld be obtained and a qualified product be obtained.

② heating time

In the process of high-frequency welding of high frequency welded pipe machine, the length of heating time is a direct factor affecting the microstructure and characteristics of the material in the heat-affected zone, which is also very important. Influence, suitable grain structure and heat flow line are the key to ensure the performance of the weld seam and the base metal. Guaranteed, so high-frequency welding usually has certain requirements for welding speed, and the speed cannot be too low, which is why. If the heating time is too long, it will not only affect the size of the heat-affected zone but also affect the grain size, resulting in grain growth and affecting the weld performance, which may cause obvious disadvantages in some weld performance experiments. Of course, if the heating time is too short, if the heating is not penetrated, cold welding will occur, which makes it impossible to complete the welding effect. Therefore, the heating time is also the key.

The above two aspects are the most essential content that needs to be considered in the welding process parameters of high frequency welded pipe machine. Through these issues, we summarize the parameters that affect the welding process, and hope that readers will have a deeper understanding of the high-frequency welding process.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province