High frequency welding of steel roll forming machine

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-25 11:30

- Pvs:

【概要描述】The welding of stainless steel pipe made by steel roll forming machine is very different from that of carbon steel pipe in terms of process. The most notable is the oxides produced by the molten stainless steel during welding. The oxide melting point of carbon steel is lower than that of the base metal, and it melts before the base metal and is more easily extruded by the extrusion roller to form burrs. The metal composition of the solution pool is very clean, and the base metal is very bonded during the forging and welding process. close. The control of stainless steel oxides is extremely difficult, which easily leads to welding defects.

High frequency welding of steel roll forming machine

【概要描述】The welding of stainless steel pipe made by steel roll forming machine is very different from that of carbon steel pipe in terms of process. The most notable is the oxides produced by the molten stainless steel during welding. The oxide melting point of carbon steel is lower than that of the base metal, and it melts before the base metal and is more easily extruded by the extrusion roller to form burrs. The metal composition of the solution pool is very clean, and the base metal is very bonded during the forging and welding process. close. The control of stainless steel oxides is extremely difficult, which easily leads to welding defects.

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-25 11:30

- Pvs:

The welding of stainless steel pipe made by steel roll forming machine is very different from that of carbon steel pipe in terms of process. The most notable is the oxides produced by the molten stainless steel during welding. The oxide melting point of carbon steel is lower than that of the base metal, and it melts before the base metal and is more easily extruded by the extrusion roller to form burrs. The metal composition of the solution pool is very clean, and the base metal is very bonded during the forging and welding process. close. The control of stainless steel oxides is extremely difficult, which easily leads to welding defects.

In stainless steel, whether austenitic or ferritic, the presence of chromium elements causes oxidation of alloying (chromium oxide, etc.) elements to be produced during the welding process. These chromium oxides are very "refractory", that is, they have a very high melting point. In fact, the melting point is higher than the stainless steel base metal itself. Because of this, the stainless steel base metal becomes soft and homogeneous before the alloy oxides at the welds are melted, making it more difficult to extrude the oxides. If these oxides are not extruded, they can lead to brittle fracture of the weld, and subsequent processing such as forming, and can lead to corrosion of the weld.

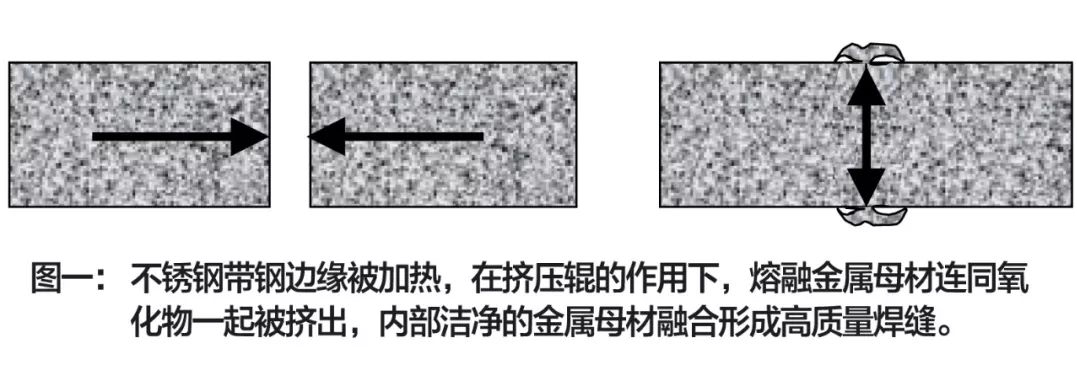

In view of this, the stainless steel tube made by the steel roll forming machine must have a suitable amount of molten base metal to be melted during welding, and the oxide is squeezed out during the extrusion of the welding point. If the process is done correctly, all the oxide will be squeezed out by the squeeze rollers, forming a uniform burr (Figure 1). If too much base metal melts, the V-angle may become unstable and cause weld defects.

Because the welding parameters are small. Therefore, when welding stainless steel, attention must be paid to the forming precision of the unit.

Material ingredient

Because carbon can combine with chromium to form very hard chromium carbides in the weld zone, keeping the carbon content low will reduce the incidence of brazing and cracking. By specifying materials such as 304L, producers will reduce welding problems and achieve higher weld quality.

Note: 304 and 304L mainly have a little difference in carbon content. The carbon content of 304 is qualified below 0.08, while the carbon content of 304L is qualified below 0.03.

Strip edge

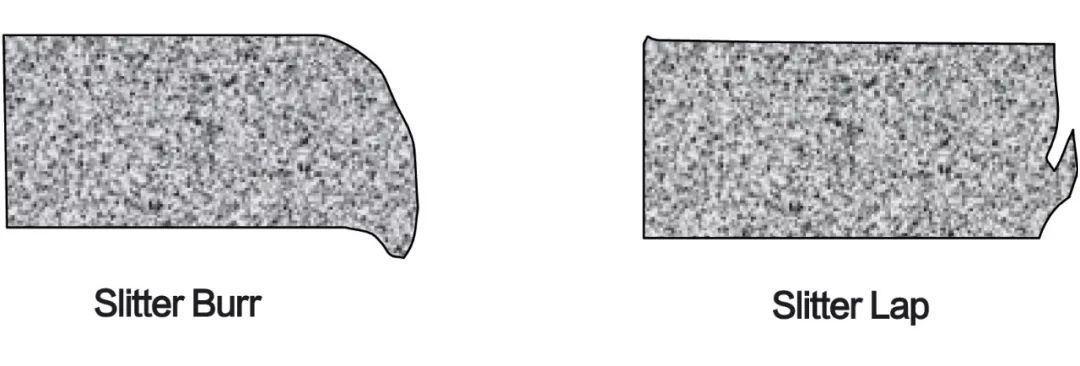

Good strip steel is an important condition for steel roll forming machine to realize stainless steel welding. The edge of the strip after slitting should be smooth and free of burrs (Figure 2). This must be handled with great care in the transportation and storage of raw materials to avoid scratches or uneven edges of the strip. Damaged edges are a common cause of welding defects.

Coil Specifications

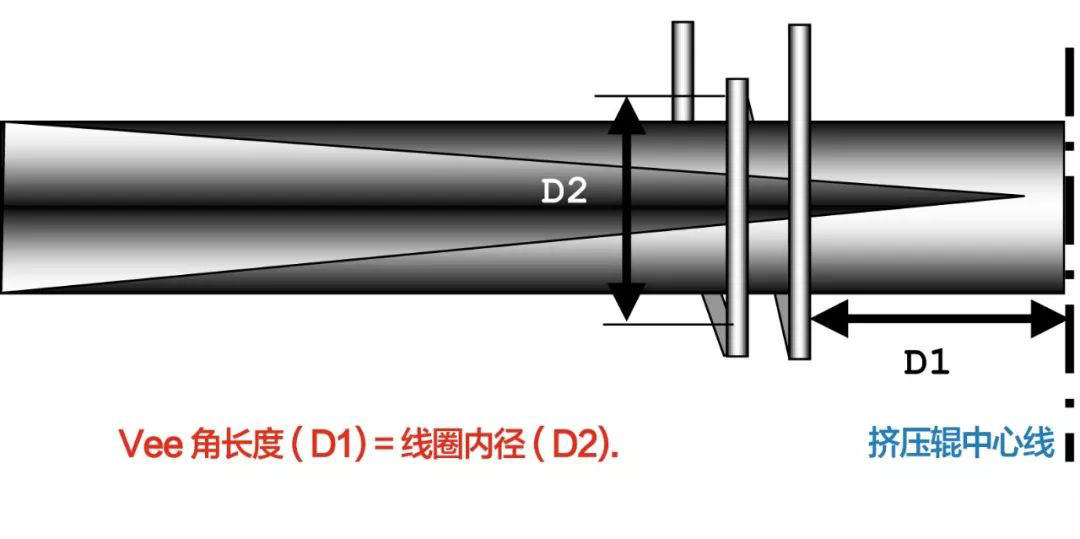

The host manufacturer and the mold manufacturer designer should calculate the detailed extrusion amount information to design the most suitable induction coil specifications.

The induction coil position is the same as the welded carbon steel pipe, and the V angle length should be approximately or equal to the inner diameter of the coil.

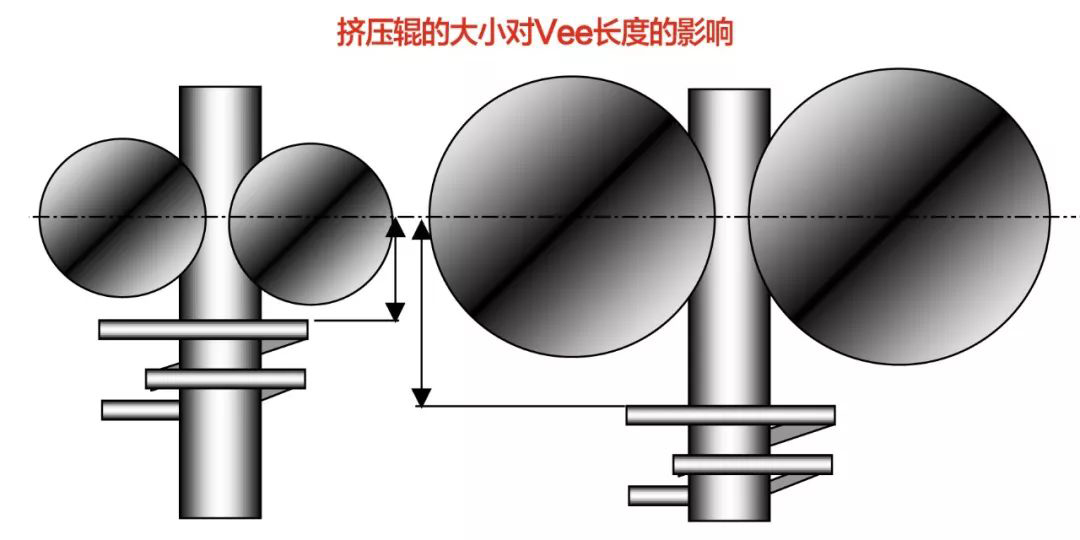

If the squeeze roll is too large, because the distance from the centerline of the squeeze roll to the coil becomes longer due to the increase in the radius of the squeeze roll, more power is required to heat the V-zone to complete the weld.

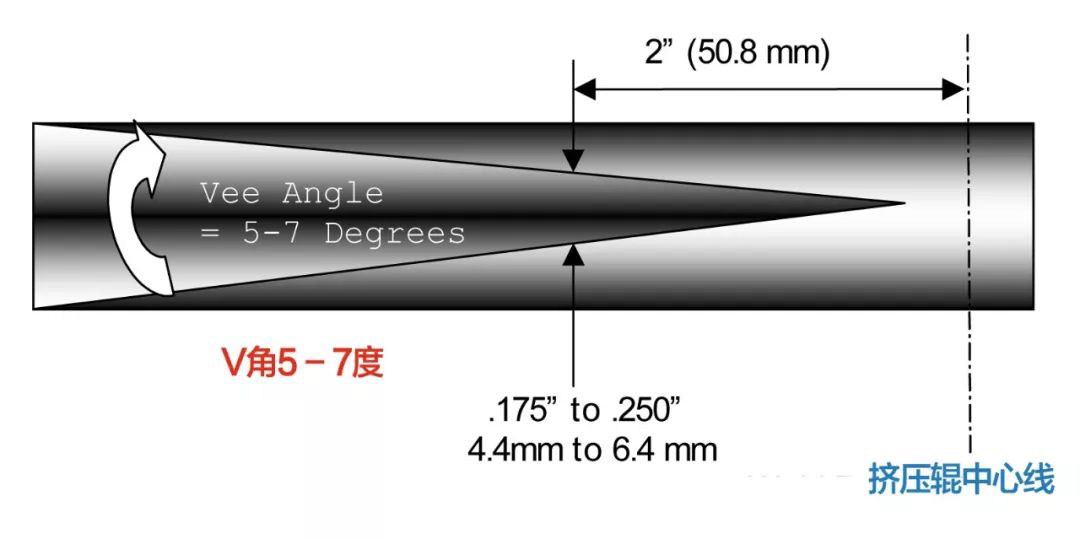

Welding V corner

The recommended VEE angle for stainless steel is between 5 and 7 degrees (Figure 3). The measured length should be 50.8mm from the centerline of the squeeze roll, and the gap between the edges of the V corner should be 4.4mm to 6.4mm.

Cool down

The most important condition for making high quality welds in stainless steel is the elimination of oxygen from the weld area. Water generates oxygen and hydrogen in the weld zone at high temperatures, providing sufficient oxygen for the formation of metal oxides. Therefore, it is vital that the welding area is kept as dry as possible.

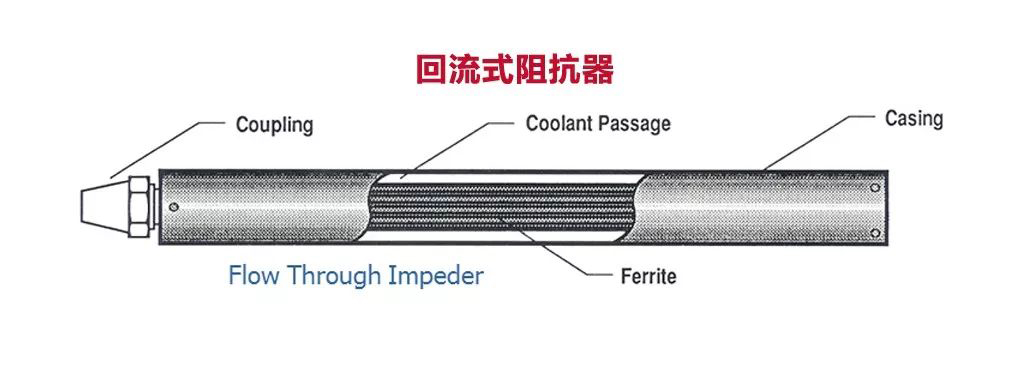

This means that water is used to cool the rolls but not into the weld V-corner, and the water used to cool the choke must pass backwards or use a return choke. The cooling water of the forming roll in the front section cannot flow into the welding area and overflow into the pipe.

Metal particles

Metal particles are generally the name given to the small metal particles produced from the high frequency welding V-zone during the welding process because of the electromagnetic force generated by the work of the current flowing in the coil (Fig. 8). The particles exist in the form of very small, spherical particles in metals and metal oxides. They are very hard and wear resistant and can damage the surface of the tube if they accumulate around the squeeze rollers for a long time.

Metal particles can also be carried backwards or build up on the coils, or even on the edges of V corners, which can cause welding defects.

Internal burr

Internal burrs formed during welding can be scraped or rolled with a carbide scraper. The decorative pipe can retain the internal burr. If there is a requirement for the internal weld, scraping is more appropriate than rolling, because the hardness of the oxide burr formed after welding is softer than the weld structure, and rolling will cause the weld to a certain extent. defect.

When using internal burr scraping tools, welding speed is relatively important. In general, the faster the unit, the better the scraping effect and the longer the tool life. Experience has shown that the speed of the stainless steel internal scraping unit should not be less than 125 ft/min (38.1 m/min)

Welding power

The optimum welding power is the minimum power that meets the quality of the welded pipe weld. Adjustment to the welding power is usually carried out by observing the "fire" taking place at the apex of the welding area. Appears yellow or orange and usually bursts on the lower part of the inner and outer welds of the tube. Stable and mild "fire" is the best indicator of full welding power and unit stability. Uneven "fire" usually indicates poor weld quality. It can be caused by mechanical irregularities in the unit, such as eccentric rolls, or excessive welding power, or both.

Manufacturers of ferritic stainless steel tubes for many automotive applications already use inspection equipment, including two-color pyrometer-based, for automated control of welding power. Once the proper temperature is confirmed, the weld temperature can be detected in real time and the power of the welder can be adjusted according to the change to achieve and maintain a consistent welding temperature.

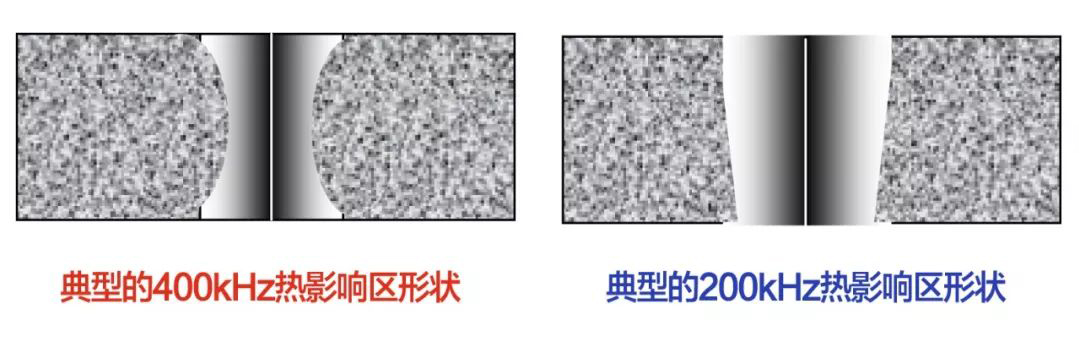

Welding frequency

The frequency is not fixed, only according to different product requirements, for example some steel roll former manufacturers prefer a welding frequency of 200 kHz because it provides a more ductile weld. Other manufacturers choose 400 kHz because of the narrow heat-affected zone that needs to be generated.

It is difficult to say what is the appropriate frequency for welding stainless steel, and which frequency really works best, because the application field of the product, strip width and width control, welding speed, extrusion amount, V angle length, frequency and welding temperature will all affect.

Therefore, the variable frequency high-frequency welding machine can provide a higher fault tolerance rate and enlarge the process window.

Inert gas protection

Shielding gas is a must if welding stainless steel is to be successful. Numerous cases illustrate that the use of shielding gases can have significant advantages when products are intended for critical applications, such as automotive tailpipes. The shielding gas of choice is argon or a mixture of argon.

A recent solution is to wrap the welding coils and squeeze rolls in a welding gas-tight box filled with argon gas. Likewise, the internal burr removal device must be sealed to prevent gas leakage from here. The idea is simple, to fundamentally prevent the formation of oxides during welding, resulting in the best weld quality.

Through the use of a sealed welding box, the generation of oxides is completely eliminated from the welding process, and the production environment of the unit must be kept relatively clean. Carbon steel pipes should not coexist with stainless steel pipes. Iron oxide particles in the carbon steel production process will be deposited on stainless steel raw materials or pipe products. In addition, iron oxide particles deposited on the edge of the V corner will also cause welding defects.

Weld Test

The perfect design of welding procedures is very important, because any deviation may lead to the final misunderstanding of raw material selection or welding defects.

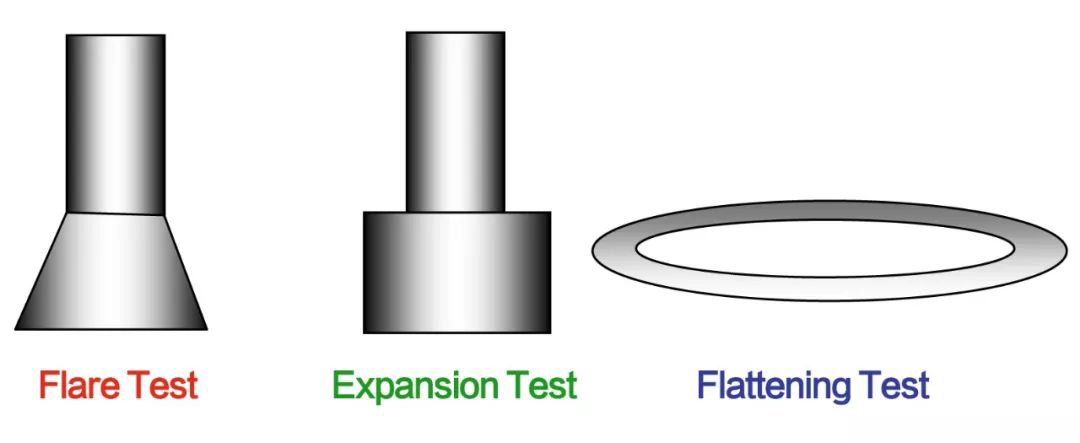

The most common tests are the flaring and flattening experiments.

Test procedures need to be carefully determined to ensure that changes introduced by human or operational influence are minimized.

For example, if the burr in the tube is not scraped or scraped too deep during flaring, the hard oxide or burr entering the heat-affected zone of the weld will cause a chain reaction of internal stress and cause the experiment to fail.

A metallographic section of the weld will show how wide and uniform the weld joint area has been. For austenitic stainless steels, the dendritic structure obtained in the metal of the metal lattice will recrystallize during the annealing process. Before annealing, however, inspection of these structures helps to assess weld uniformity and correct extrusion force.

Production

For the production of stainless steel welded pipes by steel roll forming machines, the loss of raw materials due to the consequences of poor welding is very expensive. Economically speaking, factories should be particularly cautious when welding stainless steel pipes. Standardization of parameter setting tables is absolutely necessary to ensure consistent and repeatable settings. The set-up table should include the dimensions of standard rolls, bearings, induction coils and resistors, VEE length, speed, power, welding temperature, type of shielding gas (if required), gas pressure and flow and other.

Raw materials to be procured shall have detailed order-to-written specifications: including melting, casting and rolling methods, chemical composition, gauge and metering tolerances, slot width and width tolerances, bending (camber) limitations, shipping, Loading and storage guides, and more.

Each operator or inspector should have a clear job description definition as well as the tasks to be performed, the qualifications of the personnel, and require special training or education.

In conclusion

Compared with ordinary carbon steel pipes, the high-frequency welding of stainless steel pipes in the steel roll forming machine has more difficulties in the process. The adaptability of the internal burr device, the selection of the resistor, the detection of raw materials, etc., a series of details need to be considered and arranged.

Part of the content of this site comes from the Internet. This site only provides information storage. The copyright belongs to the original author. It does not bear the relevant legal responsibility and does not represent the views and positions of this site. Please contact and delete it if there is any infringement.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province