High frequency welded pipe machine on the impact of welded tube blank defects on the quality of welded tube (10)

- Sort:Information

- Auth:

- Source:

- Release time:2022-10-13 11:30

- Pvs:

【概要描述】If the high frequency welded pipe machine refers to the chemical composition and mechanical properties of welded tube blanks that require certain inspection methods to be known as invisible defects; then, those defects that can be seen only by vision are called tube blanks. Overt defect.

High frequency welded pipe machine on the impact of welded tube blank defects on the quality of welded tube (10)

【概要描述】If the high frequency welded pipe machine refers to the chemical composition and mechanical properties of welded tube blanks that require certain inspection methods to be known as invisible defects; then, those defects that can be seen only by vision are called tube blanks. Overt defect.

- Sort:Information

- Auth:

- Source:

- Release time:2022-10-13 11:30

- Pvs:

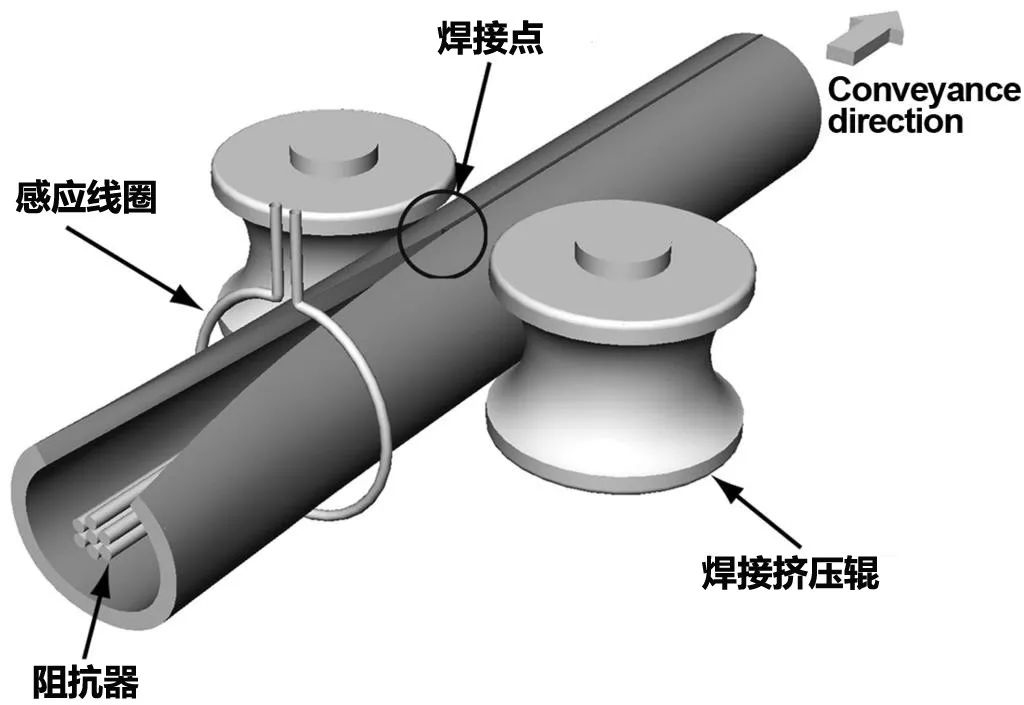

If the high frequency welded pipe machine refers to the chemical composition and mechanical properties of welded tube blanks that require certain inspection methods to be known as invisible defects; then, those defects that can be seen only by vision are called tube blanks. Overt defect.

The dominant defects of the welded tube blank of the high frequency welded pipe machine generally include cracked edges, broken edges, sawtooth, pitting, scratches, roll marks, dark spots, edge burrs, sickle bends, wrinkles, waves, edge warping, and points. Layers, warped skins, pinholes, sticky rolls, soft spots, rust, oxide layers, towers, loose rolls, etc. Let me introduce you to the causes of cracked edges and the impact of cracked edge billets on welded pipes.

Sticky tape

Adhesive tape refers to the bonding phenomenon between layers of cold-rolled annealed tube blanks or between coils. The slight adhesive tape can be pulled smoothly when the welded pipe is uncoiled, but a small tearing sound will be heard; although the moderate local adhesive tape can be pulled apart, it will tear at the bonding point, or even open, and be in the tube blank. Rough and uneven marks are left on both sides; in severe cases, the entire roll of tube billet cannot be unfolded and will be scrapped.

Reasons for sticky tape:

Adhesion mainly occurs on cold-rolled and annealed tube billets.

(1) The coolant used for cold rolling is not cleanly filtered, and a lot of metal powder remains on the surface of the cold rolled plate, and the metal powder melts during the annealing process.

(2) Tension control is still great during tension reduction rolling (no loose coils after rolling, direct annealing), and sticky tape is likely to occur during annealing.

(3) If the annealing process is not strictly implemented, spot-like local sticking will occur at the position facing the burner.

(4) The annealing process is not strictly implemented, and the cooling rate above the recrystallization temperature is too fast, resulting in the cold shrinkage of the outer ring of the steel coil too fast and too violently, resulting in a large compressive stress on the inner ring.

(5) During annealing, the temperature rises too fast above the recrystallization temperature (400~450℃).

(6) The annealing process is difficult to have the best of both worlds for thick and thin materials, wide and narrow materials, and large and small rolls. Small rolls, narrow rolls, and thick materials transfer heat quickly and are easy to heat through, resulting in uneven recrystallization recovery. When thin, wide, and large materials are also heated through, the former may have been burned.

(7) The cleaning coiling tension is too large.

(8) The annealing stack is too high.

The effect of sticky tape billet on the quality of welded pipe:

(1) Welded pipes produced with adhesive tape tube blanks cannot be used for products with higher surface requirements.

(2) For the medium-degree adhesive tape tube blanks, it is necessary to strictly select the tube blanks, but also pay attention to picking out and cutting off those pipes that penetrate through the tube, which is time-consuming and laborious, and also affects the yield rate.

Regarding the defects of the welded pipe blank of the high frequency welded pipe machine (10) the cause of the sticky tape and the influence of the sticky tape on the quality of the welded pipe, I hope it can help you.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province