High frequency welded pipe equipment to achieve seamless welded pipe

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-23 11:30

- Pvs:

【概要描述】The high frequency welded pipe equipment HFW welded steel pipe has been continuously developed with the competition with seamless steel pipe. For welded steel pipes to gradually replace seamless steel pipes, the key is to have high product quality and low production costs. Nowadays, with the advancement of steel smelting technology, hot-rolled steel strip technology and pipe-making technology, as well as the extension of process technology to specialization, differentiation and conservation, all these have created the improvement of the quality of HFW welded pipes and the reduction of costs. condition.

High frequency welded pipe equipment to achieve seamless welded pipe

【概要描述】The high frequency welded pipe equipment HFW welded steel pipe has been continuously developed with the competition with seamless steel pipe. For welded steel pipes to gradually replace seamless steel pipes, the key is to have high product quality and low production costs. Nowadays, with the advancement of steel smelting technology, hot-rolled steel strip technology and pipe-making technology, as well as the extension of process technology to specialization, differentiation and conservation, all these have created the improvement of the quality of HFW welded pipes and the reduction of costs. condition.

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-23 11:30

- Pvs:

The high frequency welded pipe equipment HFW welded steel pipe has been continuously developed with the competition with seamless steel pipe. For welded steel pipes to gradually replace seamless steel pipes, the key is to have high product quality and low production costs. Nowadays, with the advancement of steel smelting technology, hot-rolled steel strip technology and pipe-making technology, as well as the extension of process technology to specialization, differentiation and conservation, all these have created the improvement of the quality of HFW welded pipes and the reduction of costs. condition.

In order to make HFW welded pipe take advantage of uniform wall thickness, regular geometric size and low production cost, it can also overcome the inconsistency of mechanical properties and groove corrosion caused by the existence of welds, and enter the high level occupied by traditional seamless pipes. Oil and gas pipelines and oil well pipes and other fields. With the continuous progress and development of pipe making technology, the idea of seamless welded pipe was put forward. Compared with advanced foreign countries, the market share of HFW welded pipes produced by high frequency welded pipe equipment in my country is still very low, and seamless welded pipes will have a long way to go. The seamlessization of welded pipes mainly includes two connotations. One is geometric seamlessness, which uses mechanical methods and multiple hot scraping to remove burrs on the inner and outer welds of welded pipes; the other is physical seamlessness, which uses heat treatment and other processes to make the welds. , The metallographic structure and mechanical properties of the heat-affected zone (HAZ) tend to be consistent with the base material.

1.Realize the seamless production of HFW welded pipes with high frequency welded pipe equipment

1.1 HFW welding mechanism and weld characteristics

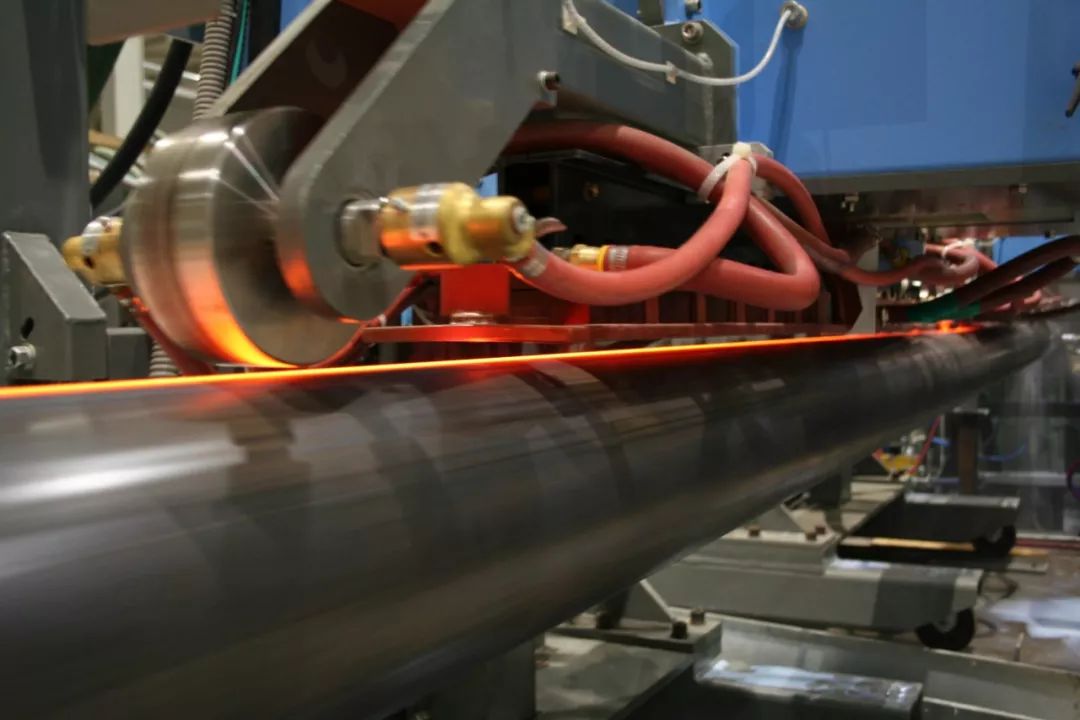

In the high-frequency welding process, the metal on both sides of the steel strip is melted through the skin effect, proximity effect, and heat conduction, and then welded into steel pipes by extrusion. During this process, characteristic areas such as melting zone and partial melting zone, superheated structure zone, normalizing zone, incomplete normalizing zone and tempering zone appeared from the edge of the steel strip. Among them, the temperature of the superheated structure during welding is at Above 1100°C, austenite grains begin to grow rapidly. Under the condition of proper chemical composition and cooling rate, some hard and brittle phases will appear, mainly martensite structure, which will reduce the comprehensive mechanical properties of this area.

In related standards such as API and ASTM, it is clearly required that the weld be heat treated or that there should be no untempered martensite in the weld. It is to heat the weld seam of HFW welded pipe to eliminate martensite to achieve the purpose of eliminating stress, uniform and refined structure, and improving the comprehensive mechanical properties of the welding heat-affected zone.

1.2 Realization of seamless welded pipe

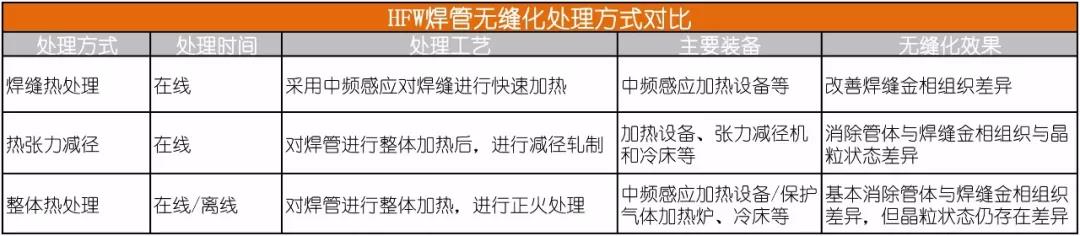

With the progress and development of HFW welded pipe manufacturing technology, currently the following three methods are mainly used for seamless treatment of welded pipes:

The first is the online heat treatment of welds;

The second is the overall heating and tension reducing rolling of the welded pipe;

The third is the overall heat treatment of the welded pipe.

See the table below for specific comparisons.

From a technical point of view, these three seamless methods are relatively mature. However, considering the equipment investment, operating cost and final product performance of high frequency welded pipe equipment, the first two methods are widely used, namely, weld heat treatment and thermal tension reduction technology.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province