Four categories of welded pipe blanks for used high frequency welded pipe equipment (3)

- Sort:Information

- Auth:

- Source:

- Release time:2023-04-08 11:30

- Pvs:

【概要描述】Welded pipe blank is the raw material of used high frequency welded pipe equipment to make welded pipe. Its mechanical properties and chemical composition have a profound impact on the quality of welded pipe, and its width is the first factor that determines the strength of the weld. We usually say that the width of the welded pipe blank is suitable, which refers to the width of the given thickness; the determination of the width is restricted by many factors.

Four categories of welded pipe blanks for used high frequency welded pipe equipment (3)

【概要描述】Welded pipe blank is the raw material of used high frequency welded pipe equipment to make welded pipe. Its mechanical properties and chemical composition have a profound impact on the quality of welded pipe, and its width is the first factor that determines the strength of the weld. We usually say that the width of the welded pipe blank is suitable, which refers to the width of the given thickness; the determination of the width is restricted by many factors.

- Sort:Information

- Auth:

- Source:

- Release time:2023-04-08 11:30

- Pvs:

Welded pipe blank is the raw material of used high frequency welded pipe equipment to make welded pipe. Its mechanical properties and chemical composition have a profound impact on the quality of welded pipe, and its width is the first factor that determines the strength of the weld. We usually say that the width of the welded pipe blank is suitable, which refers to the width of the given thickness; the determination of the width is restricted by many factors.

This article discusses various calculation methods of tube blank width, and points out the commonalities and differences of various calculation methods and their applicable conditions. At the same time, the defects of the welded pipe blanks are divided into two categories: dominant and recessive, and the adverse effects of the defects of the welded pipe blanks on the production of welded pipes are analyzed.

Classification of welded pipe blanks:

The welded pipe blanks of used high frequency welded pipe equipment can be divided into four categories according to the steel type, the temperature when rolling the pipe blank, the width of the source of the welded pipe blank and the edge state of the welded pipe blank. The following introduces the welded pipe blanks classified according to the width of the source of the welded pipe blank.

Classification according to the width of the source of the welded pipe blank

The raw materials of the welded pipe blank are divided into three types: narrow band, medium wide band and wide band according to the width, see Table 4

Narrow strip welded pipe blank

There are two types of narrow-band welded pipe blanks: one is to hot-roll the ingot into a specific width (≤400mm) and a specific thickness of hot-rolled non-trimmed welded pipe blanks according to the needs of the welded pipe specifications, which are directly used for the production of welded pipes, such as small diameter water and gas pipes. Welded tube blanks. The other is to select a narrow steel strip with a width of 400mm or less and a thickness of t according to the required width of the rolled welded pipe (φ×t).

Medium and Wide Band Welded Tube Blanks

Welded pipe blanks derived from medium and wide widths basically need to be slit and cut into pipe blanks with a width that meets the requirements of welded pipe production; of course, there are also cold and hot.

The sources of butt welded pipe blanks are classified by width, which is helpful for us to have a deeper understanding of the quality of welded pipes and to ensure the quality of welded pipes from the perspective of raw materials. Generally speaking, narrowband always has more quality defects than medium wideband, and medium wideband has more quality defects than wideband. Judging from the actual use and word-of-mouth demonstration, the comprehensive quality of the wide board is more reassuring.

The basic principle of determining the width of welded pipe blank

The basic idea of determining the width of the welded pipe blank is to manufacture a welded pipe that meets the final requirements. Under the premise of assuming that the thickness remains unchanged, it is necessary to consider the amount of narrowing of the pipe blank during the forming process, the consumption of internal and external burrs during welding, and The consumption reserved for the reduction of the diameter of the welded pipe during the sizing process, etc., in this way, the width of the pipe blank to be given must be larger than the width required for the finished pipe.

Analysis of Tube Blank Width Consumption in Shaping

According to the welding pipe production process and shaping principle, in order to obtain a finished pipe with a neutral layer diameter D, it is necessary to use a welded pipe D' larger than the neutral layer diameter to be shaped for consumption in the shaping process, so that the shaped "consumed" The width of the dropped tube blank is equal to (D'-D)π. and sizing allowance.

Analysis of Tube Blank Consumption During Extrusion Welding

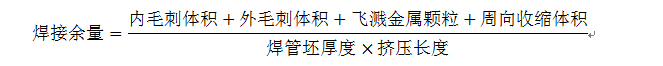

The welded pipe to be sized comes from the extrusion and welding of the pipe to be welded. It is easy to know from the principle of metal extrusion welding (forging welding). In this process, some metal will inevitably be extruded. This part of the metal that is extruded is called welding allowance before it has received extrusion welding, and this part of the allowance is specially prepared for extrusion welding. When the tube blank to be welded is extruded and welded, on the one hand, the circumference of the tube will be shortened under the action of the extrusion force of 20~40MPa; on the other hand, part of the molten metal will be extruded, and this part of the extruded metal will adhere On the inner and outer walls of the weld, they are called inner and outer burrs in the welded pipe process. Obviously, in terms of volume, if the metal particles spattered during the welding process are added, then the volume of the inner burr, outer burr, and the spattered metal particles plus the circumferential shrinkage should theoretically be exactly equal to the welding allowance. Then, the expression formula of the width of the welding allowance is as follows:

In other words, the internal and external burrs and splashed metal particles are the dominant transformation state of the width of the welded tube blank; the invisible consumption of circumferential compression is often overlooked, but this part of the consumption is the most important. It requires great attention from crew designers and adjusters.

Factors Affecting the Width of Welded Tube Blanks

The factors affecting the consumption of the welded pipe process mainly include five aspects: material, model, hole type, process and operation.

Material factor

Material factors mainly include width tolerance and thickness tolerance, strength and hardness, trimming and non-cutting.

The influence of the width tolerance on the width of the tube blank is self-evident. Taking the outer diameter of the welded pipe as an example, when its one-way tolerance exceeds 1mm, according to the calculation formula of the tube blank, it will have an impact of about 0.3mm on the outer diameter of the welded pipe.

The influence of the thickness tolerance on the width of the tube blank is mainly manifested in that the thickness can be "converted" into the width.

Influence of strength and hardness on tube width

According to the mechanical properties of metal materials, it can be said that strength and hardness are twin brothers. When the strength is high, the hardness is usually high. Strength and hardness are important indicators reflecting the ability of materials to resist elastic-plastic deformation, and are reflected in the width of the tube blank. During the process of forming, welding and sizing of the welded tube, the forming force of the tube blank in the roll pass and the longitudinal tensile stress generated by it together. Under the action, the circumference of the tube blank will be more or less reduced. The circumference of the tube blank with high strength is reduced less, and the required process allowance is less; the circumference of the tube blank with low strength is reduced more, and the required process allowance is more. Therefore, for the production of welded pipes of the same specification, the width of the high-strength tube blank should be narrower than that of the low-strength tube blank, and vice versa; especially for those special hose blanks or super-hard tube blanks, when determining This factor must be taken into account when determining the width of the blank, otherwise, it will increase the difficulty of producing this type of pipe, and it will even be impossible to produce a welded pipe with a qualified outer diameter and a qualified surface.

Influence of trimming and non-trimming on the width of tube blank

Nowadays, there are few uncut tube blanks in the production of welded pipes, so I won't go into details.

Welded pipe unit factors

Taking the adjustment accuracy as an example, the adjustment accuracy of small units is usually higher than that of large and medium-sized units. For example, the standard stipulates: for 32 units to produce φ25mm welded pipes, the maximum accuracy of the outer diameter of the pipes is ±0.1mm; for 114 units to produce φ114mm welded pipes, the highest precision It is ±0.57mm. Only the respective allowable blank width tolerance zones are ±0.35mm and ±1.79mm, respectively. Therefore, in general, when the unit is large, the requirements for the width of the tube blank are not so strict; on the contrary, when the unit is small, the requirements for the width of the tube blank must be high.

Cantilever machine and gantry machine

There are generally two types of restraint methods for the flat roll shaft of the welded pipe unit, the cantilever machine and the gantry type, and there are great differences between the force application method of the unit and the force method of the welded pipe.

The rolling force of the cantilever mill is on the side of the constraint point. After the roller is stressed, the constraint side has a tendency to rotate around the fulcrum. , which in turn affects the accuracy of the welded pipe. This feature requires that the width of the tube blank given is a little narrower than that of the gantry type.

The force of the gantry type unit, the force point is in the middle of the two restraint points, there is no rotation trend, the structure is stable, and it is stronger when it is strong. Therefore, the width of the tube blank used in the gantry type unit can be appropriately wider, and the wider part can be consumed in the closed hole section, the welding section and the sizing section in the form of longitudinal extension and circumferential contraction, which generally does not affect the accuracy of the welded pipe. Excessive influence.

Unit style

The method of cloth rolls, whether it has a vertical roll group, the traditional arch or the universal arch, and whether the two-roll extrusion method or the three-roll or multi-roll extrusion method is used, etc., all have an impact on the determination of the width of the tube blank. Taking the extrusion roller as an example, the nominal extrusion force applied by the vertical two-roll extrusion roller to the tube blank is generally larger than that of the three-roller, but the actual extrusion force received by the welding edge is not necessarily large. The former is easy to shorten the circumference of the tube blank, that is, more welding allowance is required. When calculating the width of the tube blank, it is necessary to be wider.

Hole factor

Hole type R size

If the entire set of roll passes, especially the pass R from the closed pass back, is generally designed to be small, then even after the wider tube blank enters the pass, the smaller pass will force the tube blank to produce a larger circumferential direction. Large compression; Conversely, if the roll pass R is too large, after encountering the entry of the tube blank of the same width, the circumferential compression of the pass on the tube blank will be less, and even the narrower tube blank will not show its narrowness.

Forming method

Different molding methods have different requirements for the width of the tube blank. Comparing circumferential deformation and edge deformation, the former requires a larger forming allowance than the latter. This is because: According to the deformation principle, the edge of the deformed tube blank is approximately equal to the radius R on the full width of the tube blank ¼ arc, and before entering the closed hole shape, the minimum amount of circumferential deformation can only be changed to 2 of the radius of the finished tube. However, the edge radius of the tube blank in the edge deformation method can be deformed to the radius of the finished tube, or even smaller than the radius of the finished tube. In this way, in the subsequent deformation, in order to change the edge of the tube blank by the circumferential deformation method to the radius of the finished tube, it is necessary to apply a larger radial and circumferential rolling to the edge of the tube blank by means of a closed hole shape smaller than the edge of the tube blank. force. The large rolling force reduces the radius of the edge of the tube blank, and the circumference of the tube blank is also greatly compressed (relative to the edge deformation) under the combined action of the guide ring and the pass; and the edge of the tube blank obtained by the edge deformation method It is almost the same as the radius of the closed hole type. The tube blank is only rolled by a small radial and circumferential rolling force in the closed hole type, so the perimeter of the tube blank is shortened very little. requirements are different.

Operational factors

Affected by the debugging skills, experience and sense of responsibility of the welded pipe, the width of the tube blank may be abnormally narrow or abnormally wide during the debugging operation, and even mislead the designer into thinking that the designed tube blank width is inappropriate. A typical case is: if the forming force and extrusion force applied in the forming closed-hole type stage and the welding extrusion stage are too large, the designed forming allowance and welding allowance will be insufficient, and then part of the sizing allowance will be squeezed. , there is an illusion that the sizing allowance is too small and insufficient or that there is no sizing allowance.

It can be seen that there are many factors affecting the given width of the tube blank, which need to be considered comprehensively.

The above is one of the "width of the source of the welded pipe blank" about the used high frequency welded pipe equipment. And the factors that affect the consumption of the welded pipe process mainly include five aspects: material, model, hole type, process and operation.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province