Four categories of welded pipe blanks for used high frequency welded pipe equipment (2)

- Sort:Information

- Auth:

- Source:

- Release time:2023-04-05 11:30

- Pvs:

【概要描述】Welded pipe blank is the raw material of used high frequency welded pipe equipment to make welded pipe. Its mechanical properties and chemical composition have a profound impact on the quality of welded pipe, and its width is the first factor that determines the strength of the weld. We usually say that the width of the welded pipe blank is suitable, which refers to the width of the given thickness; the determination of the width is restricted by many factors.

Four categories of welded pipe blanks for used high frequency welded pipe equipment (2)

【概要描述】Welded pipe blank is the raw material of used high frequency welded pipe equipment to make welded pipe. Its mechanical properties and chemical composition have a profound impact on the quality of welded pipe, and its width is the first factor that determines the strength of the weld. We usually say that the width of the welded pipe blank is suitable, which refers to the width of the given thickness; the determination of the width is restricted by many factors.

- Sort:Information

- Auth:

- Source:

- Release time:2023-04-05 11:30

- Pvs:

Welded pipe blank is the raw material of used high frequency welded pipe equipment to make welded pipe. Its mechanical properties and chemical composition have a profound impact on the quality of welded pipe, and its width is the first factor that determines the strength of the weld. We usually say that the width of the welded pipe blank is suitable, which refers to the width of the given thickness; the determination of the width is restricted by many factors.

This article discusses various calculation methods of tube blank width, and points out the commonalities and differences of various calculation methods and their applicable conditions. At the same time, the defects of the welded pipe blanks are divided into two categories: dominant and recessive, and the adverse effects of the defects of the welded pipe blanks on the production of welded pipes are analyzed.

Classification of welded pipe blanks:

The welded pipe blanks of used high frequency welded pipe equipment can be divided into four categories according to the steel type, the temperature when rolling the pipe blank, the width of the source of the welded pipe blank and the edge state of the welded pipe blank.The following introduces the welded pipe blanks classified according to the temperature of the rolled billet.

Classification by temperature of rolled billets

All welded pipe materials need to undergo a certain amount of rolling to become pipe blanks. According to whether the billet before rolling the billet needs to be heated and then thinned, the welded pipe billet can be divided into two categories: cold-rolled welded pipe billet and hot-rolled welded pipe billet.

Cold rolled welded pipe blank

Cold-rolled welded pipe billet refers to the use of hot-rolled strip steel as raw material, and the pickled hot-rolled strip steel is thinned at room temperature to obtain cold-rolled strip steel with a predetermined thickness, and then the strip is trimmed or not trimmed, etc. Process to obtain a welded pipe blank that meets the requirements of the width of the welded pipe material. Cold-rolled welded pipe blanks have annealing and non-annealing (commonly known as hard cold), bright annealing (with protective gas, so that it will not be oxidized) and black annealing (without protective gas, the surface of the annealed steel strip is oxidized to black), refined Straight and unfinished straightening, trimmed and untrimmed. The welded pipes produced by them in used high frequency welded pipe equipment are quite different in terms of surface and performance, such as cold-rolled annealed and cold-rolled non-annealed welded pipes. Under normal circumstances, the former is bent, flared, expanded, etc. There is no problem. The latter elbow will break, the flaring will burst, and the expanding tube will crack, so it is only suitable for direct use.

Hot rolled welded pipe blank

The billet needs to be heated to above the recrystallization temperature (800~1250°C) for rolling, and the obtained strip product is called hot-rolled steel strip; the hot-rolled billet is directly used as the raw material for welded pipes. Hot-rolled tube billets are divided into trimmed and non-trimmed.

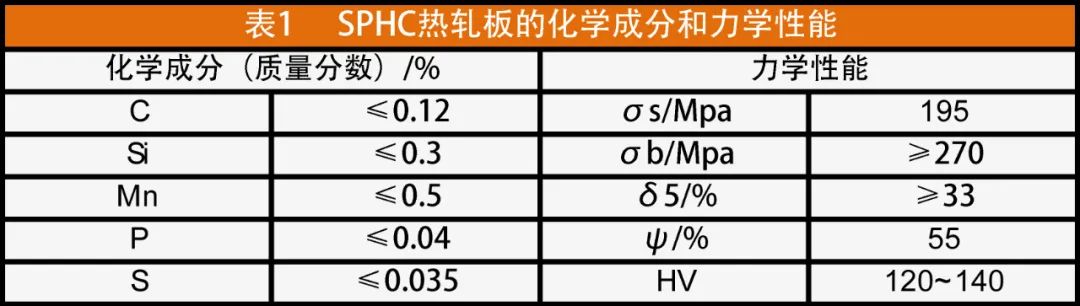

Commonly used Q195~Q235 and SPHC hot-rolled strip steel for fluid conveying pipes, structural pipes, and shelf pipes are used as welded pipe blanks. The chemical composition and mechanical properties of SPHC are shown in the following table.

The difference between cold-rolled welded pipe billet and hot-rolled welded pipe billet

(1) Process difference:

①Different temperatures: cold-rolled welded billets are rolled at room temperature (strictly speaking, below the recrystallization temperature) billets, while hot-rolled billets are rolled at room temperature for heated billets.

② Different width changes: During cold rolling, the thickness of the billet is mainly changed, and the width is slightly narrowed, which is usually ignored; during hot rolling, the thickness becomes thinner and the width becomes wider and changes at the same time.

③The rolling objects are different: the rolling object of the cold-rolled welded pipe billet is the normal temperature steel strip, and the rolling object of the hot-rolled welded pipe billet is the high-temperature steel ingot. It can also be said that the latter is the raw material of the former.

(2) Quality differences. It is mainly manifested in four aspects:

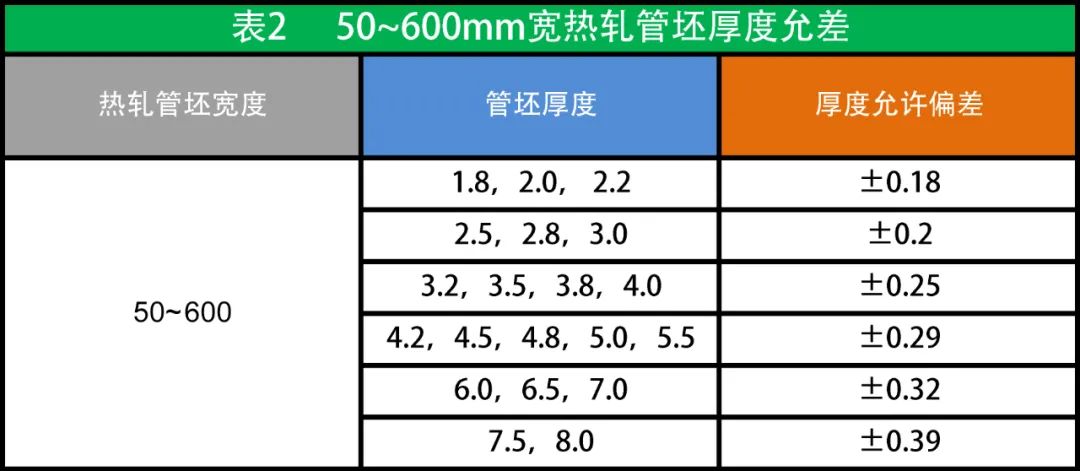

①The thickness of the cold-rolled welded pipe billet is uniform, and the general internal control is 0.01~0.03mm; of course, the international regulations are much broader. see table 2

②Through cold rolling, extremely thin welded pipe blanks that cannot be produced by hot rolling can be obtained, such as 0.1mm; the thickness tolerance of 50~600mm wide hot rolled pipe blanks is shown in Table 3

③The surface quality of the cold-rolled welded pipe blank is superior, the structure is dense, and the board surface is smooth, and there is no oxide layer intrusion, pitting, roughness and other defects that are common in the hot-rolled welded pipe blank.

④The cold-rolled welded pipe blank has good mechanical properties and process properties, such as higher strength, lower yield limit, good deep drawability, etc.

(3) Price difference:

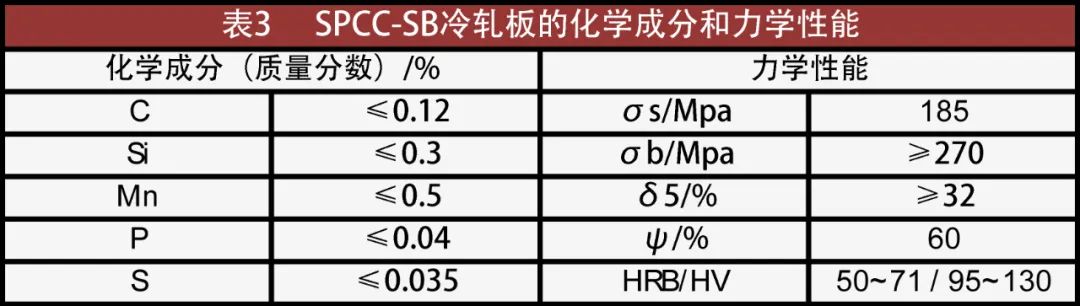

There is a lot of price difference between the cold-rolled welded pipe billet and the hot-rolled welded pipe billet, and cold rolling is more expensive than hot rolling. Among the cold-rolled steel plates used for cold-rolled welded pipe blanks, the more famous grade is SPCC-SB, which is superior to similar products in terms of comprehensive mechanical properties, plate shape and cost performance. The chemical composition of SPCC-SB for mechanical properties is shown in Table 3

The above is one of the "rolled billet temperature" about the welded pipe billet of used high frequency welded pipe equipment. From the temperature of the rolled billet, it can be divided into cold-rolled welded pipe billet and hot-rolled welded pipe billet. The difference between them lies in process difference, quality difference and price difference.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province