Forming technology of thin wall welded pipe produced by used Φ76 welded pipe units

- Sort:Information

- Auth:

- Source:

- Release time:2022-11-26 11:30

- Pvs:

【概要描述】Thin-wall welded pipes are mainly used for threading pipes, furniture pipes, transformer pipes, decorative pipes and so on. The used Φ76mm welded pipe units usually adopts the horizontal and vertical alternate arrangement and the hole pattern of the single radius circular deformation method. When producing thin-walled welded pipes and extremely thin-walled pipes, it is easy to produce strip edge waves and bulges, and the welding is very unstable, which is not conducive to Control the quality of thin-walled tube forming and welding.

Forming technology of thin wall welded pipe produced by used Φ76 welded pipe units

【概要描述】Thin-wall welded pipes are mainly used for threading pipes, furniture pipes, transformer pipes, decorative pipes and so on. The used Φ76mm welded pipe units usually adopts the horizontal and vertical alternate arrangement and the hole pattern of the single radius circular deformation method. When producing thin-walled welded pipes and extremely thin-walled pipes, it is easy to produce strip edge waves and bulges, and the welding is very unstable, which is not conducive to Control the quality of thin-walled tube forming and welding.

- Sort:Information

- Auth:

- Source:

- Release time:2022-11-26 11:30

- Pvs:

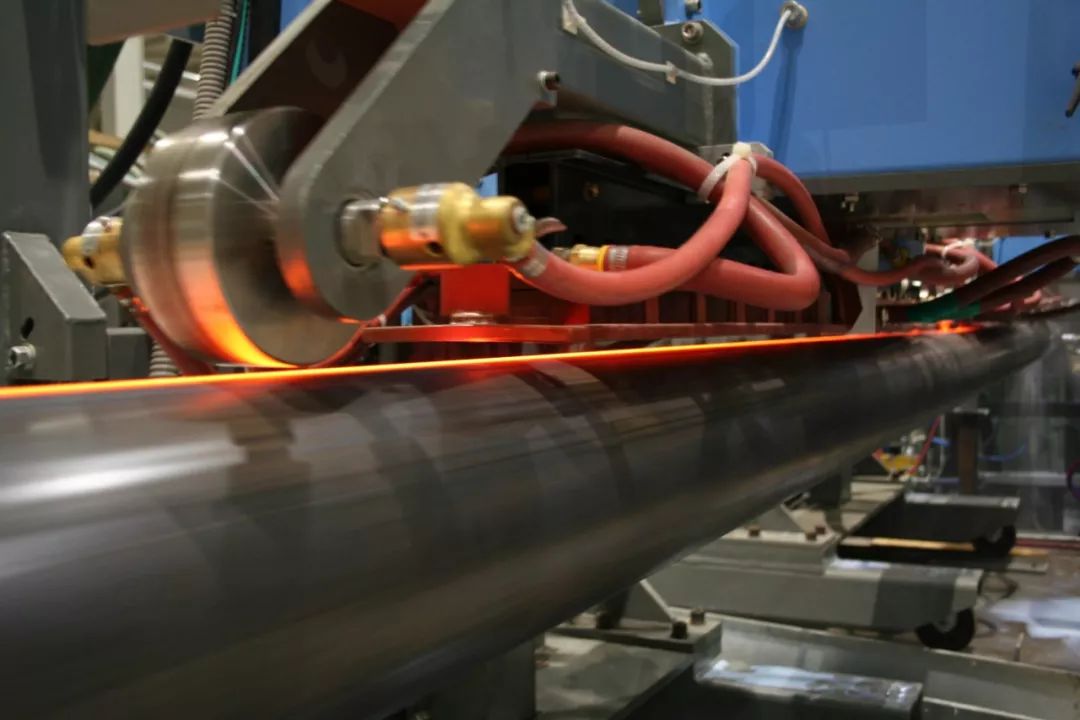

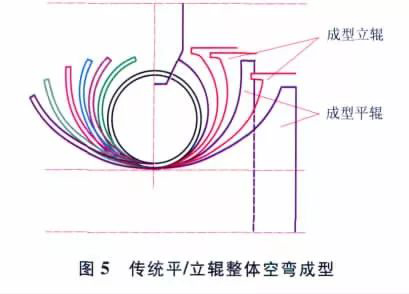

Thin-wall welded pipes are mainly used for threading pipes, furniture pipes, transformer pipes, decorative pipes and so on. The used Φ76mm welded pipe units usually adopts the horizontal and vertical alternate arrangement and the hole pattern of the single radius circular deformation method. When producing thin-walled welded pipes and extremely thin-walled pipes, it is easy to produce strip edge waves and bulges, and the welding is very unstable, which is not conducive to Control the quality of thin-walled tube forming and welding.

Forming of thin-wall welded pipe

The main problem in the forming process of thin strip steel is that when the strip steel enters the closed hole, the edge produces waves and bulges, the surface of the strip steel is ribbed, the forming is not sufficient, and the strip steel is easy to turn over.

The reason for the edge wave is that during the deformation process, the longitudinal tensile deformation of the edge part of the strip is greater than that of the central part. If this longitudinal stretching deformation is within the elastic deformation range, the strip edge will return to its original length without producing a wave shape. If the edge extension exceeds the allowable elastic deformation of the material, when the extended edge of the opening hole enters the closed hole, it cannot be restored to a straight state, and even an intermittent bulge is formed.

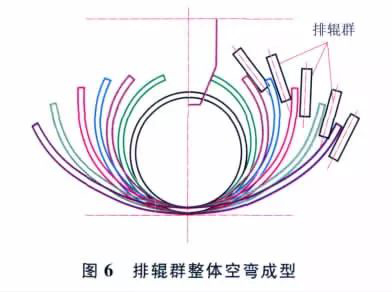

Due to the limitation of the used Φ76mm welded pipe units, it is impossible to eliminate the bulge by arranging rollers, reducing the distance between the racks, and increasing the length of the deformation zone. We have adopted the following methods:

(1)The downhill forming method can reduce the edge extension of the longitudinal deformation due to the reduction of the rising height of the edge; for the extremely thin-walled tube, the roller diameter can be appropriately increased to prevent the edge from bulging.

(2)The first round of forming adopts the method of W forming and the latter several rounds of double-radius forming. The W forming method is to first bend the middle part of the tube blank in the reverse direction, and at the same time make the edge part of the tube blank bend forward, increase the arc length of the edge, so that the edge can be fully deformed, and the maximum lift height of the strip edge can be effectively reduced , To reduce edge extension, and at the same time it is beneficial to control the tube blank turnover. Double-radius molding also plays a role in reducing edge extension and preventing edge bulging.

(3)Because the upper roll of the flat roll before the closed hole is narrow and the tube blank is not fully deformed, it is changed to a vertical roll, which becomes a vertical roll group composed of three passive vertical rolls. The deformation can be slightly larger. One can reduce the edge extension and make the deformation more tolerable; the second can reduce the abrasion of the strip surface.

(4) The configuration of the second, third, and fourth upper roller width should be paid attention to to prevent and eliminate tube ribs.

(5) Requirements for vertical roll adjustment: the centerline of vertical rolls and flat rolls should be straight, and the vertical rolls should not be high or low; the reduction should be uniform, especially the reduction of the vertical roll. If the reduction is too large, it will bulge and reduce the amount. If it is too small, it will increase the pressing amount of the next few passes and cause bulging.

(6) Appropriately increase the pressure of the opening hole during the adjustment of the forming flat roll, increase the extension of the middle of the tube blank, and reduce the uneven deformation of the strip.

The forming technology of used Φ76 welded pipe units to produce thin-walled pipes should also pay attention to the method of eliminating bulging, so as to ensure the production quality of thin-walled welded pipes, and better control of the quality of thin-walled welded pipes.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province