Form of metal streamlines for pipes made by used high frequency welded pipe equipment

- Sort:Information

- Auth:

- Source:

- Release time:2023-05-06 11:30

- Pvs:

【概要描述】The metal streamline is the most important display feature of the various forms of the weld. When the used high frequency welded pipe equipment is used to make pipes, the partially melted or semi-melted metal under certain high temperature conditions is formed under the action of pressure. The crystal structure of special shape is also a comprehensive reflection of the magnitude and direction of welding extrusion force, line energy and welding speed, and has fixed metallurgical properties.

Form of metal streamlines for pipes made by used high frequency welded pipe equipment

【概要描述】The metal streamline is the most important display feature of the various forms of the weld. When the used high frequency welded pipe equipment is used to make pipes, the partially melted or semi-melted metal under certain high temperature conditions is formed under the action of pressure. The crystal structure of special shape is also a comprehensive reflection of the magnitude and direction of welding extrusion force, line energy and welding speed, and has fixed metallurgical properties.

- Sort:Information

- Auth:

- Source:

- Release time:2023-05-06 11:30

- Pvs:

The metal streamline is the most important display feature of the various forms of the weld. When the used high frequency welded pipe equipment is used to make pipes, the partially melted or semi-melted metal under certain high temperature conditions is formed under the action of pressure. The crystal structure of special shape is also a comprehensive reflection of the magnitude and direction of welding extrusion force, line energy and welding speed, and has fixed metallurgical properties.

In order to use metal streamlines to correctly control the welding process specification, first of all, it is necessary to fully understand the various performance characteristics of metal streamlines and accurately analyze and judge the causes of various shapes, so as to play their role in the production of high-frequency welded pipes by used high frequency welded pipe equipment. proper role. The commonly used bad forms of metal streamlines are roughly as follows.

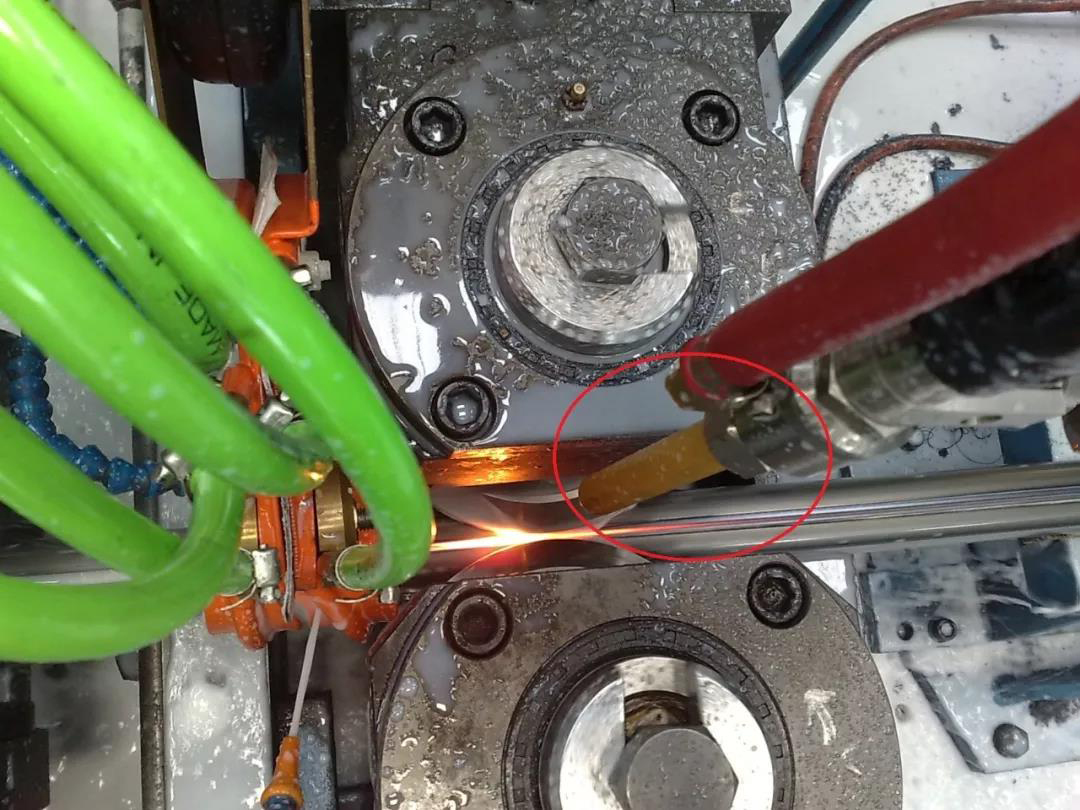

①The rising angle of the streamline is too large

Usually, the larger the rising angle of the metal streamline, the larger the extrusion force during welding. Larger extrusion force can squeeze out more molten metal, so that the metal on the edge of the plate is not welded well, and it is easy to produce "cold welding". This is a common welding defect, which generally occurs in the following two situations in production:

(1) The unwelded edge of the plate can occur on the inside of the weld or on the outside. When the inner side is not welded, the fracture is generally smooth and tidy, mostly gray, accounting for a large proportion of the weld area, and the rising angle of the streamline can sometimes reach 80°~90°; when the outer side is not welded. When the current density is too small, it is easy to cause low temperature welding, and the weld fusion is not good. In most cases, the rising angle of the streamline is smaller and the display is not very clear. In severe cases, the streamline cannot be seen clearly.

(2) The unwelded edge of the plate may also occur in the middle of the weld. This kind of defect is actually a kind of "virtual welding", the fusion line in the middle of the weld is generally slight, and sometimes it is even difficult to distinguish, and only the "waist drum" of thermal influence can be observed. The microstructure of the unwelded part is mostly "oxide inclusions" or "grey spots", with fine ferrite + pearlite on both sides. Welds with such defects are very easy to crack when subjected to a 90° flattening test.

In addition to being closely related to the welding line energy and extrusion force, the above-mentioned plate edge unwelded defects are also related to the parallelism of the plate edge during forming. The normal plate edge can ensure parallel welding, the weld gap tends to be consistent, and the penetration depth is also good; when heating and uniform extrusion along the wall thickness direction, the weld seam welding can achieve the best state, and the streamline distribution can also be formed symmetrically ; The closer the centerline of the streamline and the centerline of the coil wall thickness are, the more basic the welding quality can be, and the "oxide inclusions" or "grey spots" in the center of the weld can be completely and evenly extruded.

②The rising angle of the streamline is too small

When the line energy and welding speed remain relatively stable, if the extrusion force is too small, it is easy to cause the rising angle of the metal streamline to be small, and the streamline display is often unclear, sometimes even invisible. In this case, the fusion line in the middle of the weld is often accompanied by more "oxide inclusions", which become the crack source of weld cracking, which is a common defect affecting the quality of the welded pipe.

③The rising angle of the streamline is asymmetrical

This weld defect is mainly caused by the following three reasons:

(1) The extrusion force is unbalanced. When adjusting the squeezing rollers, the distribution of the squeezing force of the top roller or the rollers on both sides is asymmetrical, which is easy to cause different changes in the shape of the streamline. Some rising angles are too small, the streamlines are subtle or unclear; It is too large, the streamline is very thick, the display is abnormal, and it presents various forms. If the edge of the plate is not parallel, it is easy to produce misalignment on the weld, resulting in unidirectional loss of weld metal and stress concentration, and the probability of defects in the weld will also increase. Special attention must be paid when adjusting the roll.

(2) The parallelism of the board edge is not good. The edges of the board are not parallel, and "∨" and "∧" shapes are easy to appear. Since high-frequency welding is the result of the proximity effect and the skin effect of the board edges, if the board edges are not parallel, the high-frequency current distribution will be uneven, the local temperature difference will be significant, and the board edges will not be in synchronous contact to achieve tight welding.

When the edge of the board is "∨" shape. The inner edge of the weld should be in contact before the outer edge, so the current density of the inner edge is higher, and the heating temperature is higher than that of the outer edge. Therefore, under the condition of the same extrusion force, the rising angle of the metal streamline of the inner wall that contacts first is larger, while the rising angle of the metal streamline of the outer wall is significantly smaller, and even no streamline is displayed in severe cases.

When the edge of the plate is "∧" shape, the outer wall of the welded pipe is in contact with each other before the inner wall, so the proximity effect of the outer wall is stronger than that of the inner wall, the current density is higher, and the welding temperature is higher. The outer burr is thicker than the inner burr, and the rising angle of the metal streamline is obviously larger than that of the inner wall of the welded pipe.

(3) The parallelism of the board edge is unreasonable. This may bend the edge of the rolled plate, easily causing the edge to be "wavy", increasing the tendency to form "grey spots"; at the same time, there may be "displacement" at the welding seam during forming and continue to the welding point. where the solidifying weld metal will be "biased" or cracked.

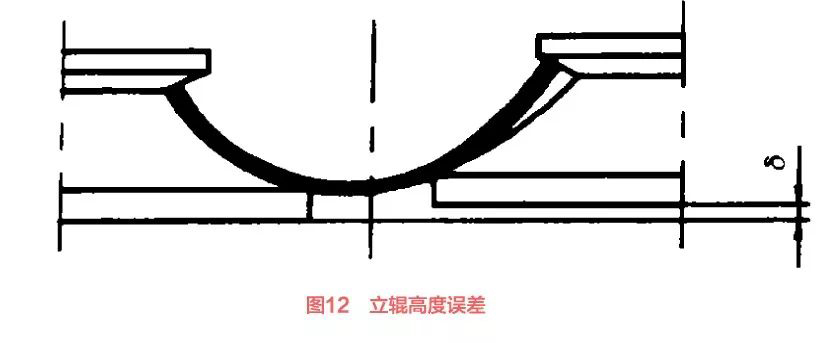

④The center distance is too large

The center distance is the distance between the center line of the metal streamline and the center line of the wall thickness of the coiled plate. In addition to being related to the smoothness of the extrusion force, the parallelism of the plate edge also has a great influence on it.

(1) When the extrusion force is not adjusted properly, the center line of the metal streamline may be down if it is not up, and it is difficult to match the center line of the coil wall thickness. The larger the center distance is, the more uneven the distance between the butt joints is, and the "wrong side" is easy to occur at the weld, the "oxide inclusions" are difficult to extrude, and the welding quality is also worse; when the center distance is close to zero. The welding point can be close to the center of the extrusion roller, the extrusion force distribution is more uniform, and the welding quality can reach the best state.

(2) When the sides of the coil are not parallel, it is easy to cause the center distance to be too large. It is difficult to achieve parallel joints, the thermal effect of local solder joints may be reduced, a low-temperature welding state occurs, oxides in the welds are difficult to remove, and the tendency to form "grey spots" increases. When the center distance reaches 1/2 of the coil wall thickness, The weld metal is easy to be discharged in one direction, and the opposite side is easy to form "grey spots", or local poor welding.

In addition to the above four kinds of bad forms, when the extrusion force is constant, if the welding line energy and welding speed are too large, the metal cooling speed is quite fast, and the structure of the weld and heat-affected zone is mostly coarse iron wire and block. Flake pearlite, the needle-like Widmandelweiss structure remaining in the structure, is difficult to eliminate in the post-weld tempering heat treatment (600-650 ℃), and the fusion line and flow line of the weld often show poor shape. It is easy to produce large stress concentration at the welding seam, which is enough to cause the "bow" bending deformation of the welded pipe, and even lead to the cracking of the welding seam.

Summary: The common bad forms of metal streamlines in high-frequency welded pipes when making pipes with used high frequency welded pipe equipment are roughly as follows: ① The rising angle of the streamlines is too large. ②The rising angle of the streamline is too small. ③ The rising angle of the streamline is asymmetrical. ④The center distance is too large.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province