Factors and various influences to ensure the quality of used high frequency welded pipe machine welded pipe products(1)

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-19 11:30

- Pvs:

【概要描述】In the process of producing welded pipes with used high frequency welded pipe machine, how to ensure that the product quality meets the requirements of technical standards and the needs of customers, it is necessary to analyze the factors affecting product quality in the production process of steel pipes.

Factors and various influences to ensure the quality of used high frequency welded pipe machine welded pipe products(1)

【概要描述】In the process of producing welded pipes with used high frequency welded pipe machine, how to ensure that the product quality meets the requirements of technical standards and the needs of customers, it is necessary to analyze the factors affecting product quality in the production process of steel pipes.

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-19 11:30

- Pvs:

In the process of producing welded pipes with used high frequency welded pipe machine, how to ensure that the product quality meets the requirements of technical standards and the needs of customers, it is necessary to analyze the factors affecting product quality in the production process of steel pipes.

Through the statistics of unqualified products of a Φ76mm high-frequency welded steel pipe unit in a certain month, it is believed that the factors affecting the quality of steel pipe products in the production process include raw materials, welding process, roll adjustment, roll material, equipment failure, production environment and other reasons . seven aspects. Among them, raw materials account for 32.44%, welding process accounts for 24.85%, roll adjustment accounts for 22.72%, and the three together account for 80.01%, which are the main links. The four factors, such as roll material, equipment failure, production environment and other reasons, account for 19.99% of the impact on the quality of steel pipe products, which are relatively minor links. Therefore, in the process of steel pipe production, the three links of raw materials, welding process and roll adjustment should be controlled.

The influence of raw materials on the welding quality of steel pipes

The main factors affecting the quality of raw materials are the unstable mechanical properties of the steel strip, the surface defects of the steel strip and the large deviation of geometric dimensions. Therefore, key control should be carried out from these three aspects.

Influence of mechanical properties of steel strips on the quality of steel pipes

The commonly used steel grades for welded steel pipes are carbon structural steel, the main grades are Q195, Q215, Q235, SPCC, SS400, SPHC and so on. The yield point and tensile strength of the steel strip are too high, which will make the forming of the steel strip difficult, especially when the pipe wall is thick, the resilience of the material is large, and the steel pipe has a large deformation stress when welding the used high frequency welded pipe machine. the weld is prone to cracks. When the tensile strength of the steel strip exceeds 635 MPa and the elongation is less than 10 %, the welding seam of the steel strip is prone to cracking during the welding process. When the tensile strength is lower than 300MPa, the surface of the steel strip is easy to wrinkle due to the soft material during the forming process. It can be seen that the mechanical properties of the material have a great influence on the quality of the steel pipe, and the quality of the steel pipe should be effectively controlled from the aspect of material strength.

Influence of Surface Defects of Steel Strip on the Quality of Steel Pipe

Common surface defects of steel strips include camber, wavy, slitting edge, etc. camber and wavy generally appear in the rolling process of cold-rolled steel strip, which is caused by improper control of reduction. In the process of steel pipe forming, the camber bend and wave shape will cause the strip to deviate or turn over, which is easy to cause lap welding of the steel pipe weld and affect the quality of the steel pipe. The gnawing edge of the steel strip (that is, the phenomenon that the edge of the steel strip is jagged and uneven) generally occurs on the slitting belt, which is caused by the blunt or unsharp edge of the slitting machine disc. Due to the gnawing of the steel strip, there is always a local lack of meat, which makes the steel strip prone to cracks and cracks during welding and affects the stability of the weld quality.

Influence of the geometrical dimensions of the steel strip on the quality of the steel pipe

When the width of the steel strip is less than the allowable deviation, the extrusion force when welding the steel pipe is reduced, so that the welding seam of the steel tube is not firmly welded, and cracks or open pipes appear; when the width of the steel strip is greater than the allowable deviation, the welding of the steel pipe will The extrusion force increases, and welding defects such as sharp nose, lap welding or burr appear at the welding seam of the steel pipe. Therefore, the fluctuation of the width of the steel strip not only affects the accuracy of the outer diameter of the steel pipe, but also seriously affects the surface quality of the steel pipe. For the steel pipe that requires the wall thickness difference of the same section not to exceed the specified value, that is, the steel pipe that requires a high degree of uniformity of wall thickness, the fluctuation of the thickness of the steel strip will transfer the excess of the allowable value of the thickness difference of the same coil of steel strip to the wall thickness difference of the finished steel pipe. , so that the thickness of a large number of steel pipes exceeds the allowable deviation and is discarded. The thickness fluctuation not only affects the thickness accuracy of the finished steel pipe, but at the same time, due to the different thickness of the steel strip, the extrusion force and welding temperature of the steel pipe are unstable during welding, resulting in unstable weld quality during welding of the steel pipe. In addition, due to the existence of interlayer, impurities, trachoma and other material defects in the steel, it is also an important factor affecting the quality of the steel pipe. Therefore, before the steel strip is welded, the surface quality and geometric dimensions of each roll of steel strip should be checked. If the quality of the steel strip does not meet the standard requirements, do not carry out production, so as to avoid unnecessary losses.

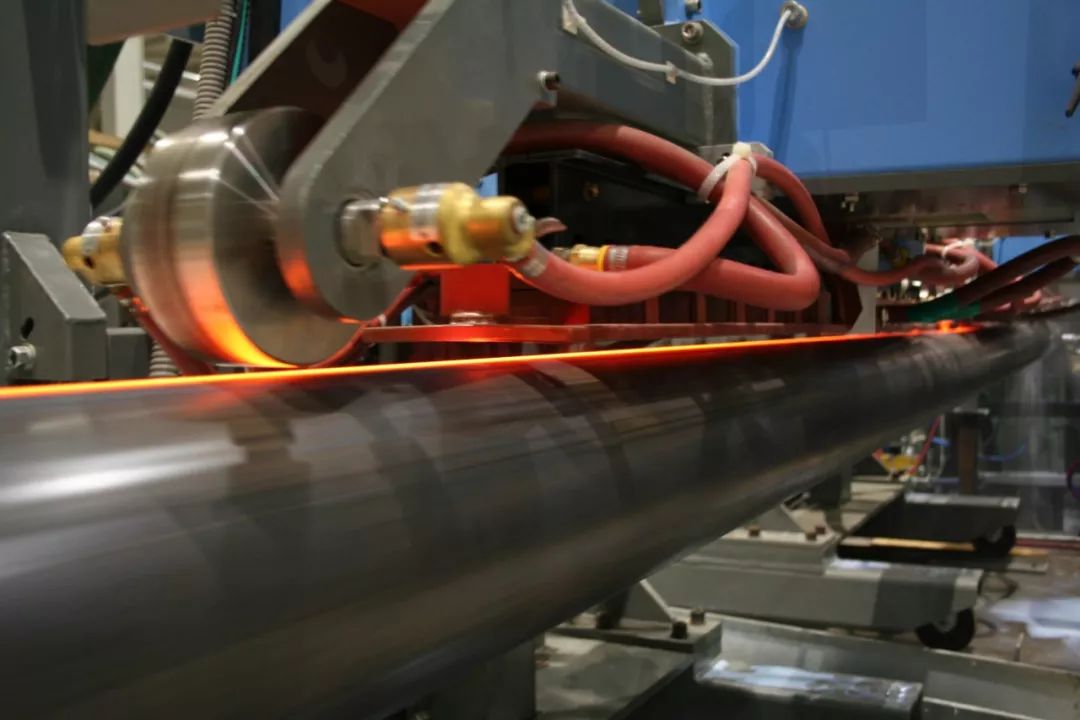

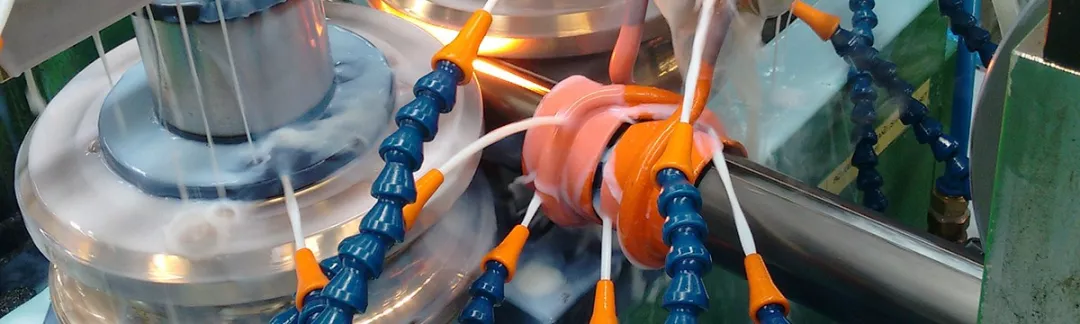

Influence of high frequency welding on the quality of steel pipes

In the process of high-frequency welding of steel pipes in used high frequency welded pipe machine, the control of welding process and process parameters, the placement of induction coils and impedance resistors, etc. have a great influence on the welding quality of steel pipe welds.

Influence of roll adjustment on steel pipe quality

It can be seen from the causal analysis diagram of steel pipe waste that roll adjustment is an operation process of steel pipe. In the production process of used high frequency welded pipe machine, when the rolls are damaged or severely worn, some of the rolls need to be replaced on the unit, or a certain variety has been continuously produced in sufficient quantities, and the entire set of rolls needs to be replaced. At this time, the rolls should be adjusted to obtain good steel pipe quality. If the rolls are not well adjusted, it is easy to cause defects such as twisting, lap welding, edge waves, bulges and indentations or scratches on the surface of the pipe body, large ovality of the steel pipe, etc. Skill.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province