Factors affecting the effective power output of high frequency welded pipe machines(2)

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-12 11:30

- Pvs:

【概要描述】There are 7 factors that affect the effective power output of the high frequency welded pipe machines. Below we will introduce in detail according to these 7 factors, respectively, ①The V angle of the welded pipe. ②The shape of the two welding surfaces of the welded pipe. ③The distance between the solder joint and the center of the squeeze roller. ④ Welding temperature. ⑤The size, size, location and cooling method of the impedance device (magnet rod array). ⑥The physical characteristics of the steel pipe itself, such as diameter, wall thickness, material, etc. ⑦The design of induction coil.

Factors affecting the effective power output of high frequency welded pipe machines(2)

【概要描述】There are 7 factors that affect the effective power output of the high frequency welded pipe machines. Below we will introduce in detail according to these 7 factors, respectively, ①The V angle of the welded pipe. ②The shape of the two welding surfaces of the welded pipe. ③The distance between the solder joint and the center of the squeeze roller. ④ Welding temperature. ⑤The size, size, location and cooling method of the impedance device (magnet rod array). ⑥The physical characteristics of the steel pipe itself, such as diameter, wall thickness, material, etc. ⑦The design of induction coil.

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-12 11:30

- Pvs:

There are 7 factors that affect the effective power output of the high frequency welded pipe machines. Below we will introduce in detail according to these 7 factors, respectively, ①The V angle of the welded pipe. ②The shape of the two welding surfaces of the welded pipe. ③The distance between the solder joint and the center of the squeeze roller. ④ Welding temperature. ⑤The size, size, location and cooling method of the impedance device (magnet rod array). ⑥The physical characteristics of the steel pipe itself, such as diameter, wall thickness, material, etc. ⑦The design of induction coil.

⑤The size, size, location and cooling method of the impedance device (magnet rod array). The main function of the impedance device is to collect and evenly distribute the current on the inner and outer walls of the tube, and it is generally placed at a distance of 200-300mm from the weld.

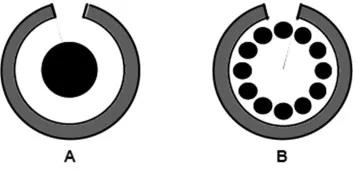

Generally good resistors have a high magnetic saturation function and a high content of ferrite. Its common physical structure is shown in the figure below:

The two magnetic rod construction methods in the above picture are often used by manufacturers. Method B has more obvious effects and higher efficiency because the magnetic field is closer to the tube wall. How does the mysterious resistor in the high frequency welded pipe machines work?

⑥The physical characteristics of the steel pipe itself, such as diameter, wall thickness, material, etc. Generally, the welding frequency of steel pipes with large wall thickness and large diameter is relatively low, on the contrary, the welding frequency is relatively high. This is because a high-frequency current has a permeability. The higher the frequency, the more concentrated the current on the surface of the steel pipe. The lower the frequency, the higher the permeability.

⑦The design of the induction coil plays a vital role in the effective power output of the high-frequency power supply.

The above are the 7 factors that affect the effective power output of the high frequency welded pipe machines. We can eliminate hidden dangers based on the impact of these seven factors on the effective power of the used high frequency pipe welding machines.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province