Discussion on the service life of welded pipe rolls of metal roll forming machine

- Sort:Information

- Auth:

- Source:

- Release time:2023-03-16 11:30

- Pvs:

【概要描述】In the production of metal roll forming machine, rolls are important key tools. Roll consumption is also an important economic indicator for controlling production costs. In addition, whether the roll can work normally will directly affect the output and quality of welded pipe production, so welded pipe manufacturers attach great importance to and strive to improve the life of the roll.

Discussion on the service life of welded pipe rolls of metal roll forming machine

【概要描述】In the production of metal roll forming machine, rolls are important key tools. Roll consumption is also an important economic indicator for controlling production costs. In addition, whether the roll can work normally will directly affect the output and quality of welded pipe production, so welded pipe manufacturers attach great importance to and strive to improve the life of the roll.

- Sort:Information

- Auth:

- Source:

- Release time:2023-03-16 11:30

- Pvs:

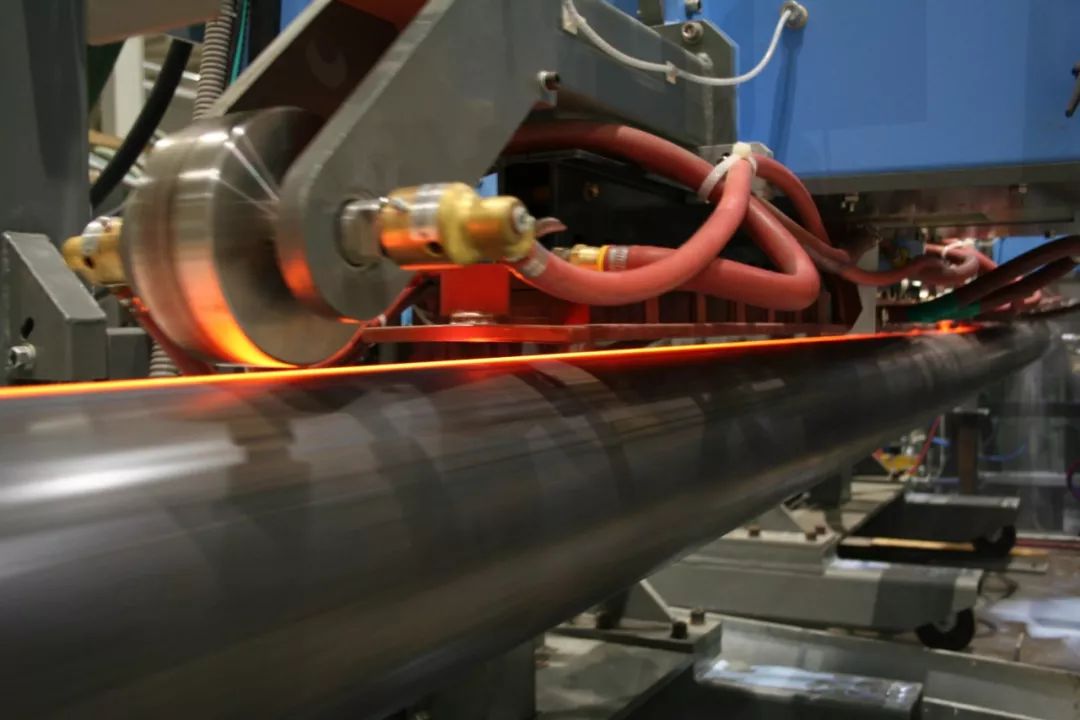

In the production of metal roll forming machine, rolls are important key tools. Roll consumption is also an important economic indicator for controlling production costs. In addition, whether the roll can work normally will directly affect the output and quality of welded pipe production, so welded pipe manufacturers attach great importance to and strive to improve the life of the roll.

Selection of High Frequency Welded Pipe Roll Material

The material of the roll directly affects the life of the roll. The material selection of the roll should be comprehensively considered from the following aspects:

① There should be high and uniform hardness and wear resistance, and the extrusion roller should also have good heat resistance.

② There should be sufficient strength (including fatigue strength) and appropriate toughness.

③ It must have good cutting performance, heat treatment performance and cold working performance.

④ The price of materials should be cheap and easy to obtain

⑤ Different materials should be selected for rolls in different working environments.

Damaged forms of rolls

There are many different forms of damage to the rolls of metal roll forming machine.

Some damage will occur suddenly, while others may occur gradually. The damage forms of the rolls are as follows.

Defects related to roll manufacturing

①Defects of raw materials: sometimes there are interlayers, or longitudinal and transverse cracks inside the material. And the inhomogeneity of the material organization or composition will also cause the poor performance of the roll, causing premature damage to some places.

②Heat treatment defects: The hardened layer of the roll is too thin, too thick and uneven, which will cause uneven wear surface in the future. In addition, poor microstructure and insignificant cracks and stress concentration during heat treatment can also cause roll damage.

③Other: Stress concentration caused by design or machining (residual blade traces, insufficient transition fillet at steps, poor keyway corners or other chamfers, etc.), as well as improper repair welding or surfacing, or improper welding methods, Causes cracks in the heat-affected zone.

Fractures related to unit operation

①Hot cracking and spalling are important factors that limit the service life of the roll. These defects are related to the production process of the unit. After these factors cause damage to the surface of the roll, the roll pass must be trimmed by grinding. If the grinding amount is too large, it will directly affect the service life of the roll.

②Burning cracking of rolls: Burning cracking is generally regarded as the early form of hot cracking and a thermal fatigue phenomenon. Due to the influence of thermal stress, network cracks or cracks are formed on the surface of the roll. These cracks deepened with the extension of rolling time. This phenomenon occurs especially in high-frequency welded squeeze rolls.

③Peeling of the roll: This is a kind of fatigue fracture, which is in the form of large peeling off of the roll body or small shallow peeling locally. The generation of spalling originates from the action of thermal and mechanical forces. Severe cyclic stress, work hardening, etc. also affect the generation of spalling.

The main causes of roll peeling include:

①The load is too heavy;

②The rolling mill vibrates, and the convex surface of the roll is not suitable;

③ Incorrect cooling, the roller is severely scratched;

④ Improper use and operation;

⑤ The fatigue strength of the roll material is low

Overloading is one of the important and common causes of spalling, and overloading is caused by many factors. Bulk spalling is generally the result of the combined effects of large external stress, thermal stress and internal stress.

Wear of rolls

form of roll wear

According to the damage mechanism of wear, wear can be divided into:

①Adhesive wear:

In the production process of high-frequency welded pipe, the pipe blank is deformed and formed successively in the roll pass. The worse the surface roughness of the roll pass, the smaller the actual contact area between the roll pass and the tube blank, and the greater the pressure on the actual contact surface. In this way, the hard and tough hole-shaped metal and the softer blank are plastically deformed, so that the adhesion phenomenon occurs at the direct contact between the two metal surfaces. Adhesive wear occurs because of the continuous formation and destruction of the adhesions (dots).

②Abrasive wear:

In the production of metal roll forming machine, because the tube blank often has hard sand oxides, iron filings (powder) or other hard debris. These harmful substances become the abrasives for the relative movement of the tube blank and the roll pass, which will scratch or deepen the damage to the roll pass. When some of these substances have high hardness on the surface of the roll pass, it can directly play a cutting role, thereby causing abrasive wear on the pass surface.

③ Corrosion and wear:

In the production of high-frequency welded pipes, cooling liquid is usually used to cool the rolls. However, when the coolant composition is improper or contains corrosive chemicals, it can cause corrosive wear on the rolls.

④Surface fatigue wear:

When the tube blank is formed in the roll pass, the contact surface between the two will periodically appear rolling or rolling sliding compound friction. Under the action of such alternating stress, the roll pass can be fatigued and cause the roll fatigue wear. .

Factors Influencing Fatigue Wear on Roll Surface

①The influence of the quality of steel:

Steel sometimes contains oxides, nitrides, silicates, and various other complex components. Such non-metallic inclusions destroy the continuity of the steel matrix and have a serious impact on fatigue wear.

② Influence of carburized layer of carburized steel on surface fatigue wear:

The decarburization of the carburized steel surface makes the stability of austenite poor, the martensite content changes, troostite or sorbite appears locally, and the residual stress distribution of the surface layer changes, thereby reducing the shear strength of the surface layer and making the roll resistant to fatigue wear. Lifespan is reduced. Reasonably increasing the hardness of the carburized steel core can significantly improve the surface fatigue wear resistance.

A thicker carburized layer can improve the fatigue wear resistance, so that fatigue cracks can be generated in the hardened layer. If the carburized layer is too shallow, fatigue cracks will occur in the transition area between the hardened layer and the core, which is easy to form surface layer fragmentation and spalling.

Methods to reduce roll wear

One of the main reasons for roll wear is wear. Adding lubricants to the roll pass surface is the most effective way to reduce roll wear. There are usually three ways to add lubricant to the roll pass:

①Add pure lubricant to the roll

②The lubricant is added to the cooling water of the rolling mill and sprayed onto the surface of the roll pass through the cooling system of the rolling mill

③ Water and lubricant are mixed in a predetermined proportion, and sprayed to the roll pass through a nozzle separate from the second cooling system of the rolling mill

Our company has many brands and wide resources, there is always one suitable for you. You only need to tell us your pipe manufacturing needs, our company will provide you with used welded pipe equipments that really suits your needs, welcome new and old customers to come to consult and order.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province