Correlation between the properties of the heat-affected zone of the weld seam of the steel roll forming machine and the main welding process parameters

- Sort:Information

- Auth:

- Source:

- Release time:2023-03-10 11:30

- Pvs:

【概要描述】The properties of the heat-affected zone of the weld seam of the steel roll forming machine are closely related to the quality of the welded pipe. The width, metal streamline angle and metallographic structure of the weld heat-affected zone under different process parameters are studied by examples, and the microscopic approach that is conducive to stability and improving the welding quality of the welded pipe is explored.

Correlation between the properties of the heat-affected zone of the weld seam of the steel roll forming machine and the main welding process parameters

【概要描述】The properties of the heat-affected zone of the weld seam of the steel roll forming machine are closely related to the quality of the welded pipe. The width, metal streamline angle and metallographic structure of the weld heat-affected zone under different process parameters are studied by examples, and the microscopic approach that is conducive to stability and improving the welding quality of the welded pipe is explored.

- Sort:Information

- Auth:

- Source:

- Release time:2023-03-10 11:30

- Pvs:

The properties of the heat-affected zone of the weld seam of the steel roll forming machine are closely related to the quality of the welded pipe. The width, metal streamline angle and metallographic structure of the weld heat-affected zone under different process parameters are studied by examples, and the microscopic approach that is conducive to stability and improving the welding quality of the welded pipe is explored.

1. Correlation between the properties of the weld heat-affected zone and the main welding process parameters

The shape and width of the heat-affected zone of the weld are closely related to the welding speed, temperature, extrusion force and even the thickness of the tube blank. When the welding speed is constant, the width of the heat-affected zone is proportional to the welding temperature (that is, the higher the temperature, the larger the width), and inversely proportional to the extrusion force (the greater the extrusion force, the smaller the width); when the extrusion When the force is constant, the width of the heat-affected zone is proportional to the welding temperature (that is, the higher the temperature, the larger the width), and inversely proportional to the welding speed (that is, the faster the speed, the smaller the width); when the welding temperature is constant, the heat The width of the affected area is inversely proportional to the extrusion force (that is, the greater the extrusion force, the smaller the width), and it is also inversely proportional to the welding speed (that is, the faster the speed, the smaller the width). It can be seen that the welding process of the welded pipe of the steel roll forming machine should be within the safe allowable range, and the potential of the welded pipe equipment should be fully exploited. Under the condition of output, gradually increase the welding speed, apply appropriate extrusion force to form the ideal shape of the heat affected zone, and run stably in this state, the welding quality will be steadily improved.

It is generally believed that the width of the heat affected zone should be 1/4~1/3 of the thickness of the tube blank, the width of the fusion line should be 0.02~0.12mm, and the metal streamline angle should be between 45°~60°. Sample experiments (including frequent flattening and flaring experiments for control re-examination) and analysis of hundreds of metallographic pictures show that the width of the heat-affected zone can be greater than 1/3. , can even be close to 1/2 of the wall thickness; the metal streamline angle can also be slightly less than 45°, and it can be kept above 40°; and the corresponding fusion line width can also be slightly wider, generally less than 0.14mm. Can.

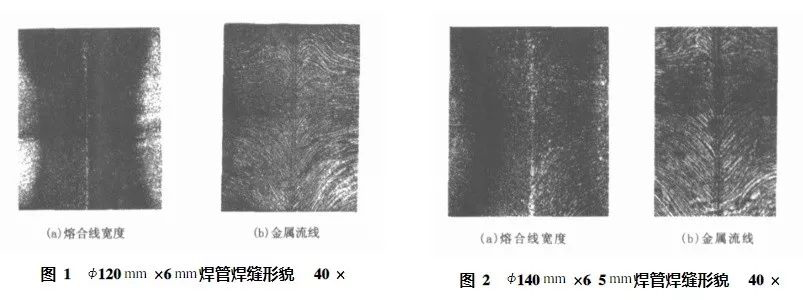

Table 1 lists the width of the heat-affected zone of the weld and the fusion line when the welding quality of the two kinds of welded pipes produced by our company is qualified (such as chemical composition, mechanical properties, and grain size of metallographic structure F+P are qualified). Measured data of width and metal streamline angle (Fig. 1~Fig. 2).

The shape of the welding heat-affected zone of the steel roll forming machine is closely related to the selection of the welding process parameters. For welded pipes with different wall thicknesses, the width of the welding heat-affected zone and the metal streamline are allowed to have a certain difference. When the value of t/D ratio (Note 2) increases, corresponding technical measures should be taken to seek reasonable heat-affected zone properties, which is conducive to stably improving the quality of welded pipes.

Note 2: t/D ratio is the ratio of wall thickness (Thickness) and pipe diameter (Diameter)

Our company has many brands and wide resources, there is always one suitable for you. You only need to tell us your pipe manufacturing needs, our company will provide you with used welded pipe equipments that really suits your needs, welcome new and old customers to come to consult and order.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province