Control the best efficiency of the operation and welding process of high frequency welded pipe equipment (2)

- Sort:Information

- Auth:

- Source:

- Release time:2022-11-24 11:30

- Pvs:

【概要描述】In the high-frequency welding of high frequency welded pipe equipment , the welding power is generally above 100KW, and 80% of the power is consumed in the heating of the coil, the resistance, and the heating of the pressure roller and the tube blank.

Control the best efficiency of the operation and welding process of high frequency welded pipe equipment (2)

【概要描述】In the high-frequency welding of high frequency welded pipe equipment , the welding power is generally above 100KW, and 80% of the power is consumed in the heating of the coil, the resistance, and the heating of the pressure roller and the tube blank.

- Sort:Information

- Auth:

- Source:

- Release time:2022-11-24 11:30

- Pvs:

In the high-frequency welding of high frequency welded pipe equipment , the welding power is generally above 100KW, and 80% of the power is consumed in the heating of the coil, the resistance, and the heating of the pressure roller and the tube blank.

Therefore, the key to minimizing power loss is to set up reasonable coils, resistors and reasonable configuration of rolling mills. In most cases, after optimizing the welding process, power loss can be reduced by 50%, and welding quality can be improved, downtime can be reduced, and output can be increased.

How to control the best efficiency of the operating and welding process of high frequency welded pipe equipment can be divided into 8 types, and we will introduce 2 of them below: ④Edge state. ⑤V-shaped area shape.

④Edge state

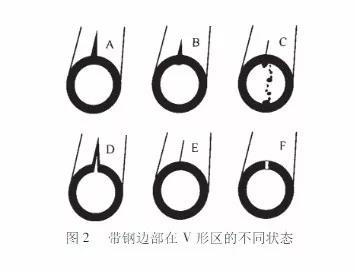

There are burrs or irregular shapes at the edge of the steel strip in the V-shaped zone, which will increase the welding heat loss, increase the amount of extruded metal, and produce irregular weld beads, which will easily lead to welding defects. In Figure 2, A~C is the bad edge state: the inner surface of the strip meets first in the V-shaped area, and a large amount of current flows through the inner surface, causing the metal in the inner surface of the weld zone to be overheated and melted, resulting in a large number of weld beads. In order to weld through the entire wall thickness, more power will be consumed. However, D~F in Figure 2 are in a relatively good welding edge state, that is, the strip steel edges are butted in parallel in the V-shaped area.

⑤V-shaped area shape

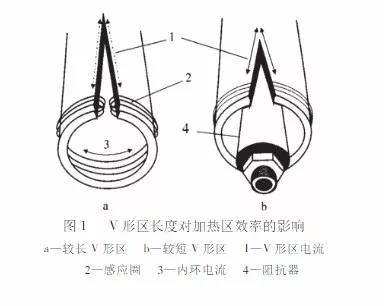

From the standpoint of maximizing efficiency, the V-shaped zone should be as short as possible (to reduce conduction loss). In actual production, a squeeze roller of a certain size is installed in the V-shaped area to keep the induction coil away from the apex of the V-shaped area. In addition, the thickness of the tube wall also affects the length of the V-shaped zone. The high frequency current first heats the confluence point of the two sides of the strip in the V-shaped zone, so that the heating zone appears as a funnel. If the V-shaped zone is too short, the edges of the strip will be unevenly heated, which will result in incomplete welding or overburning and decarburization of the weld zone.

The heating of the V-shaped zone of the strip starts from its induction coil. It is usually inappropriate to use the distance from the end of the induction coil to the confluence point of the steel edge as the measured length of the V-shaped zone. The distance from the middle of the induction coil to the confluence point should be taken as the length of the V-shaped zone (usually 1.5 times the pipe diameter). However, the length of the V-shaped zone of large pipe diameter and thin-walled pipes should be reduced, and the length of the V-shaped zone of welded pipes smaller than φ25.4mm (1") should be increased due to the limitation of the squeeze roller structure size.

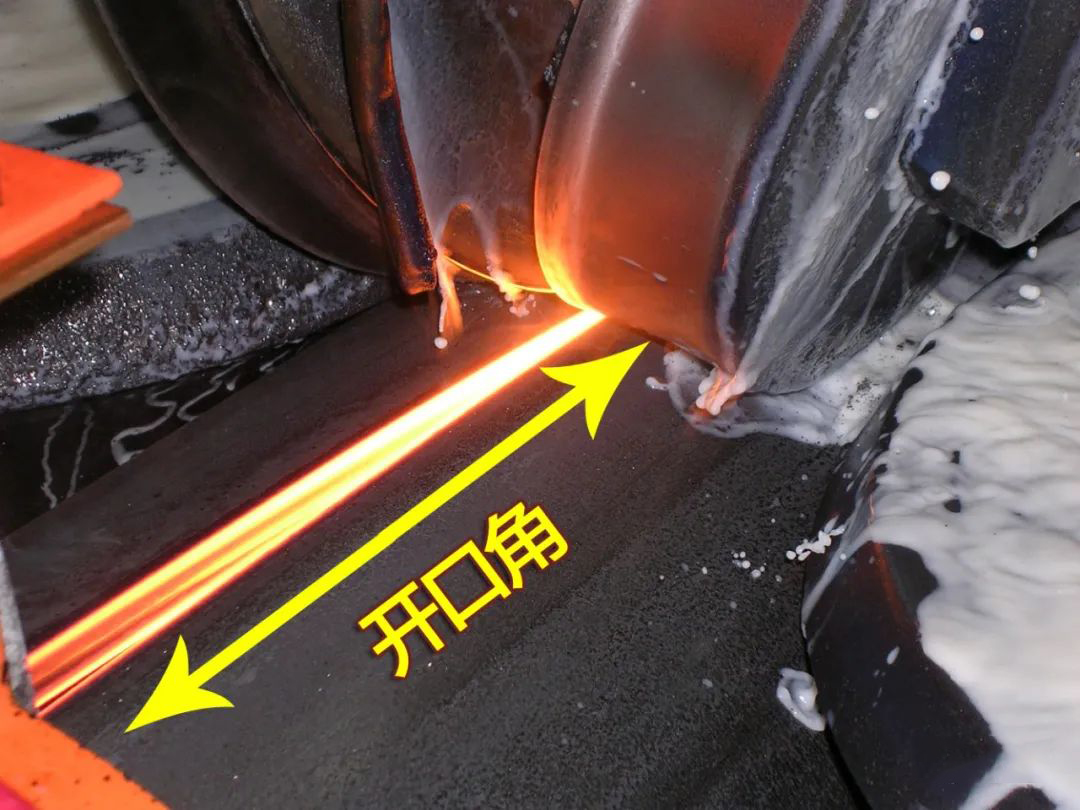

The confluence angle of the two sides of the steel strip in the V-shaped zone also affects the welding efficiency. A smaller confluence angle requires smaller welding power, which not only concentrates the proximity effect, but also helps to reduce the magnetic flux in the resistor and solve the problem of limited space for the resistor at a certain welding speed. However, a too small confluence angle can easily lead to "sparking" and aggravate the instability of the strip in the frame and the wear of the roller shaft. Generally speaking, the best confluence angle for welding carbon steel is 3°~4°, and the ideal confluence angle for welding stainless steel and non-ferrous metals is 5°~8°.

The above is to control the best efficiency of the welding process of the high frequency welded pipe equipment (2). I hope it will be of some help to you. Our company has many brands and resources, and there is always one that suits you. You only need to inform us of your pipe-making needs, and our company will provide you with used welded pipe equipment that really suits your needs. Welcome new and old customers to consult and order.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province