Common welding defects of used high frequency welded pipe equipment (1)

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-25 11:30

- Pvs:

【概要描述】There may be various defects in the used high frequency welded pipe equipment, and the names of defects are not completely uniform. Combined with the characteristics of our welded pipe production, the defects that often occur are as follows:①Inclusions; ②Insufficient fusion; ③Stick welding; ④Cast welding;Not all of these defects are present, but they are often found in high-frequency welded pipes.

Common welding defects of used high frequency welded pipe equipment (1)

【概要描述】There may be various defects in the used high frequency welded pipe equipment, and the names of defects are not completely uniform. Combined with the characteristics of our welded pipe production, the defects that often occur are as follows:①Inclusions; ②Insufficient fusion; ③Stick welding; ④Cast welding;Not all of these defects are present, but they are often found in high-frequency welded pipes.

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-25 11:30

- Pvs:

There may be various defects in the used high frequency welded pipe equipment, and the names of defects are not completely uniform. Combined with the characteristics of our welded pipe production, the defects that often occur are as follows:

①Inclusions; ②Insufficient fusion; ③Stick welding; ④Cast welding;

Not all of these defects are present, but they are often found in high-frequency welded pipes.

The schematic diagrams provided below are not actual pictures of each defect, and are mainly used to illustrate the main characteristics of the defect, and do not mistakenly believe that welding defects are only produced under a specific process condition. The defect shown in the text is the fracture morphology of the weld cracked by the flattening test.

Common inclusion defects in welding of used high frequency welded pipe equipment can be divided into : ① overburned inclusions; ② oxidized inclusions.

Inclusions - Black Overfired Inclusions

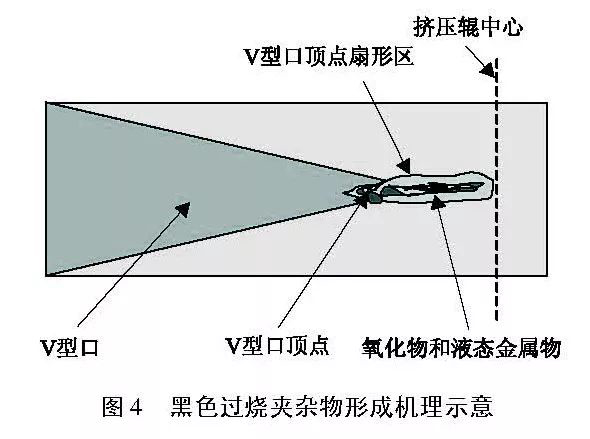

This type of defect is that the metal oxide is not clamped on the molten surface with the extrusion of the molten metal, and is formed on the surface of the molten metal at the V-shaped mouth. At the V-shaped mouth, if the approach speed of the steel strip edge is less than the melting speed, the melting speed is higher than the discharge speed of the molten metal. After the apex of the V-shaped mouth, a narrow sector containing molten metal and metal oxides is formed. The metal oxide cannot be completely discharged after normal extrusion, thus forming an inclusion band, as shown in Figure 4.

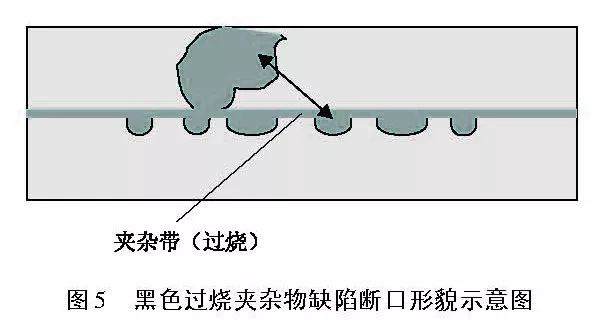

After the weld is flattened, black overburned inclusions are easily seen at the weld fracture. Compared with the fibrous fracture of the welded seam, the black over-burned inclusions have a flat fracture and no metallic luster. Such defects may appear singly or in chains. As shown in Figure 5.

When the angle of the V-shaped mouth is narrowed, for example, the angle is less than 4° or the ratio of silicon to manganese in the steel is less than 8:1, the probability of inclusions increases. However, the ratio of silicon-manganese in steel is difficult to control compared with other influencing factors, which mainly depends on the chemical composition of the base metal.

Preventive measures for black overburning inclusions:

①V-shaped angle is controlled at 4°~6°;

②Reliable tooling equipment installation ensures stable V-shaped length;

③ Relatively low welding temperature obtains better weld quality;

④ Avoid that the ratio of silicon to manganese in the chemical composition of the base metal of the steel strip is less than 8:1.

Inclusions - white peroxide inclusions

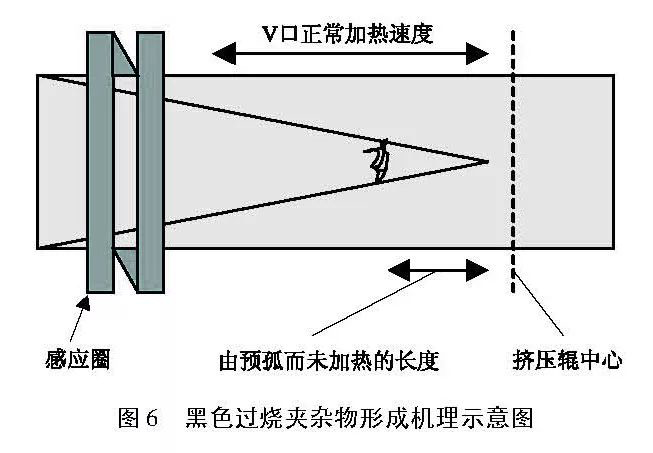

This type of defect is called white peroxide inclusion, which is not accurate. In the case of used high frequency welded pipe equipment, burrs or rust form a bridge before falling to the apex of the V-shaped mouth, resulting in a short circuit and a pre-arc phenomenon caused by current jumping. The short-circuit current instantly changes the current direction, reducing the heat of the V-port, as shown in Figure 6.

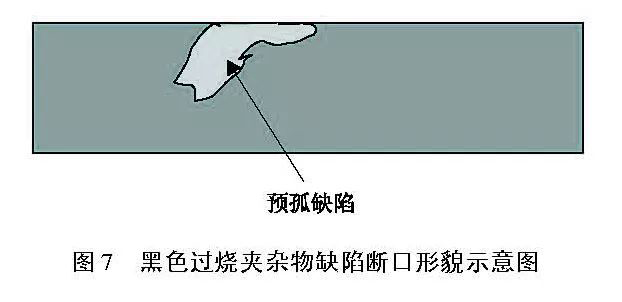

The instantaneous current produces very small defects. Generally, the length of the defect does not exceed the wall thickness. From the weld fracture, a small bright, flat plane can be seen surrounded by fibrous fractures, as shown in Figure 7.

White Peroxide Inclusion Defect Prevention Measures:

①The angle of V-shaped mouth is controlled at 4°~6°;

②Reduce cutting edge burrs;

③ Appropriate edge treatment or reduce the edge damage of the steel strip;

④Keep the cooling water clean and do not flow to the V-shaped port.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province