Common welding defects of high frequency welded pipe equipment (3)

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-13 11:30

- Pvs:

【概要描述】There may be various defects in the high frequency welded pipe equipment, and the names of defects are not completely uniform. Combined with the characteristics of our welded pipe production, the defects that often occur are as follows:①Inclusions; ②Insufficient fusion; ③Stick welding; ④Cast welding;Not all of these defects are present, but they are often found in high-frequency welded pipes.

Common welding defects of high frequency welded pipe equipment (3)

【概要描述】There may be various defects in the high frequency welded pipe equipment, and the names of defects are not completely uniform. Combined with the characteristics of our welded pipe production, the defects that often occur are as follows:①Inclusions; ②Insufficient fusion; ③Stick welding; ④Cast welding;Not all of these defects are present, but they are often found in high-frequency welded pipes.

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-13 11:30

- Pvs:

There may be various defects in the high frequency welded pipe equipment, and the names of defects are not completely uniform. Combined with the characteristics of our welded pipe production, the defects that often occur are as follows:

①Inclusions; ②Insufficient fusion; ③Stick welding; ④Cast welding;

Not all of these defects are present, but they are often found in high-frequency welded pipes.

The schematic diagrams provided below are not actual pictures of each defect, and are mainly used to illustrate the main characteristics of the defect, and do not mistakenly believe that welding defects are only produced under a specific process condition. The defect shown in the text is the fracture morphology of the weld cracked by the flattening test.

Other common welding defects of high frequency welded pipe equipment can be divided into ① casting welding (brittle welding); ② porosity (pinhole); ③ jump welding.

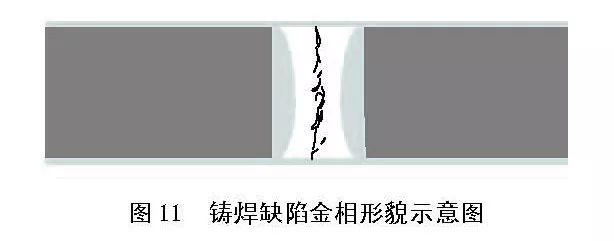

Cast welding (brittle welding)

Casting welding means that the molten metal on the joint surface is not fully discharged, and the as-cast metal on the fusion surface contains metal oxides like peroxidation, and the fracture morphology changes according to the residual as-cast metal content. Now most of them show flat and brittle morphology, and metallographic inspection can see that there is as-cast metal on the joint surface, as shown in Figure 11. The cast welded pipe cracks when it is flattened.

Preventive measures for casting welding:

①Increase welding discharge;

②Increase the width of the steel strip.

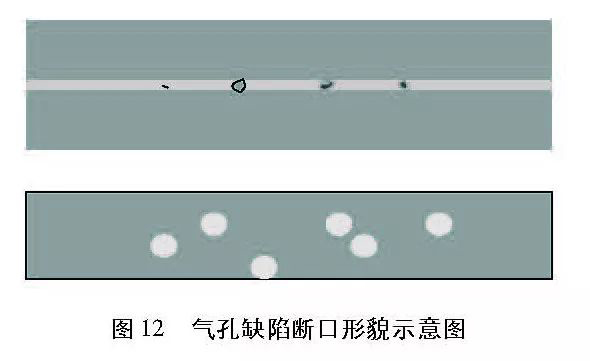

Air holes (pinholes)

The pores on the welding joint surface of the high frequency welded pipe equipment are caused by high temperature welding but insufficient discharge. The fracture morphology is fibrous, and the spherical bright white dots are randomly distributed on the entire fracture. When the white dots appear on the outer wall, the surface phenomenon of the white dots turns black due to oxidation. As shown in Figure 12.

Small pores can be seen before the outer burr is removed, and pores can also be seen on the fusion line after the outer burr is removed.

Preventive measures for stomata:

①Reduce welding input;

②Increase the amount of extrusion.

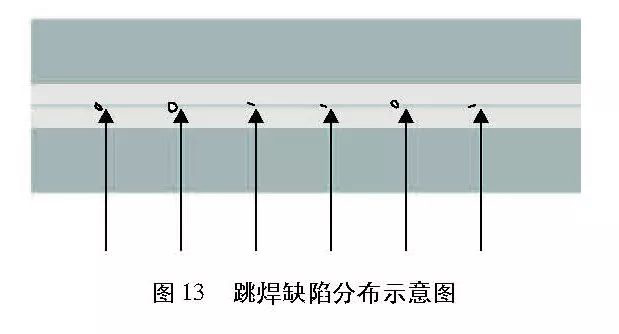

Jump welding

There are various forms of jump welding, as shown in Figure 13.

Usually, such defects are distributed regularly and continuously, and the defects outside the wall thickness are similar to wavy defects, and the spacing is generally equidistant.

Precautions for jump welding:

① Filter equipment to increase welding current;

②Check the input voltage;

③ Check the rollers and shafts.

Part of the content of this site comes from the Internet. This site only provides information storage. The copyright belongs to the original author. It does not bear the relevant legal responsibility and does not represent the views and positions of this site. Please contact and delete it if there is any infringement.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province