Common problems in welding of high frequency welded pipe equipment (3) —— according to the shape reason and adjustment method of the wrong side

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-04 11:30

- Pvs:

【概要描述】The high frequency welded pipe equipment is the core equipment of the entire HFW production line, and it is also the equipment with the highest technical requirements. If it is adjusted improperly, it will directly affect the quality of the welded pipe. This article takes five-roll extrusion welding as an example to introduce the used high frequency tube mills in detail. Common problems of high-frequency welding of machines (3)——According to the shape reason and adjustment method of the wrong edge.

Common problems in welding of high frequency welded pipe equipment (3) —— according to the shape reason and adjustment method of the wrong side

【概要描述】The high frequency welded pipe equipment is the core equipment of the entire HFW production line, and it is also the equipment with the highest technical requirements. If it is adjusted improperly, it will directly affect the quality of the welded pipe. This article takes five-roll extrusion welding as an example to introduce the used high frequency tube mills in detail. Common problems of high-frequency welding of machines (3)——According to the shape reason and adjustment method of the wrong edge.

- Sort:Information

- Auth:

- Source:

- Release time:2022-09-04 11:30

- Pvs:

The high frequency welded pipe equipment is the core equipment of the entire HFW production line, and it is also the equipment with the highest technical requirements. If it is adjusted improperly, it will directly affect the quality of the welded pipe. This article takes five-roll extrusion welding as an example to introduce the high frequency welded pipe equipment in detail. Common problems of high-frequency welding of machines (3)——According to the shape reason and adjustment method of the wrong edge.

The shape and adjustment of the wrong side

When the high frequency welded pipe equipment runs high-frequency welding, the wrong edge of the plate edge (also called lap welding) often occurs. In addition, the wrong edge of the plate edge is an important reason that affects the welding quality. If the adjustment is improper, the wrong edge will appear, which reduces the effective wall thickness of the welding seam, and it is easy to cause stress concentration here.

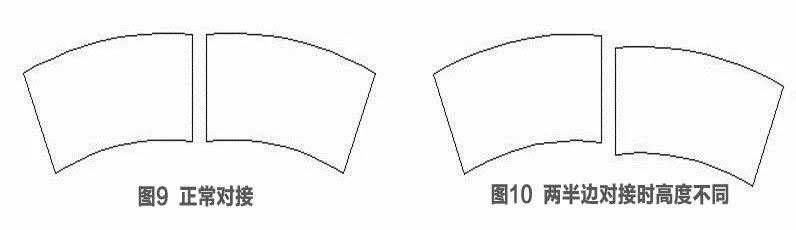

Fig. 9 shows the shape of normal docking.

Figure 10 shows the wrong edge caused by the different height of the board edge, which is a common welding wrong edge.

The reasons for the wrong edge in Figure 10 are:

(1) In most cases, the height of the two upper squeezing rollers is different. Therefore, it can be corrected by adjusting the height of one of the upper squeezing rollers.

(2) Sometimes it is caused by the different heights of the welding squeeze side rollers, which can be corrected by adding or subtracting metal gaskets at the bottom or side of the squeezing side roller frame.

Figure 11 shows the edge misalignment caused by the different angles of the welded plates. Such misalignment can easily cause the welding burrs to fall to one side. The metallographic test of high-frequency welding shows the bending of the fusion line or the asymmetrical angle of the left and right streamlines of the fusion line.

Reasons for such wrong edges:

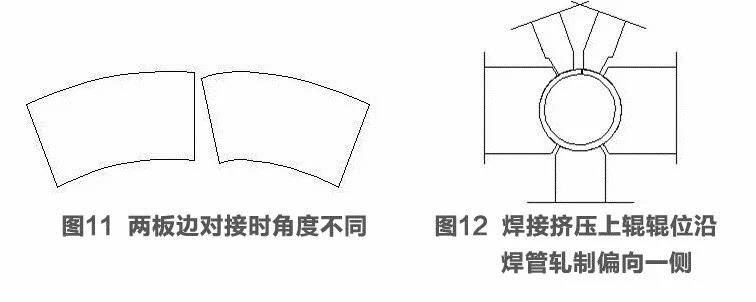

(1) The roller position of the upper welding roller is asymmetrical along the rolling center of the welded pipe, which causes the two upper rollers to exert unequal force on the two plate edges. The upper roller frame can be adjusted horizontally to make the entire upper roller simultaneously Move to the left or right, and finally reach the center of the upper squeeze roller (Figure 12).

(2) The height of the two squeezing side rollers is different or the squeezing roller frame is inclined.

(3) Reasons for edge quality. The strip steel has defects such as sickle bends, wavy bends, etc., or the single side plate edge of the strip steel is worn out.

The above problems are the reasons for the shape and adjustment methods of the wrong side of the high frequency welded pipe equipment during high-frequency welding. I hope to give you effective help.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province