Common problems and solutions for burr removal in used roll forming equipment (2)

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-15 11:30

- Pvs:

【概要描述】Internal burrs often appear when used roll forming equipment is used to make pipes, and there will also be many problems in removing internal burrs. We explain and deal with common problems in removing burrs from welded pipes.

Common problems and solutions for burr removal in used roll forming equipment (2)

【概要描述】Internal burrs often appear when used roll forming equipment is used to make pipes, and there will also be many problems in removing internal burrs. We explain and deal with common problems in removing burrs from welded pipes.

- Sort:Information

- Auth:

- Source:

- Release time:2023-02-15 11:30

- Pvs:

Internal burrs often appear when used roll forming equipment is used to make pipes, and there will also be many problems in removing internal burrs. We explain and deal with common problems in removing burrs from welded pipes.

There are 9 common problems in removing internal burrs with used roll forming equipment: ① The output power is too large. ②Welded weld bead. ③ The inner burr ring knife breaks down. ④ The residual height of the inner burr exceeds the standard. ⑤ The weld is in the shape of a peach. ⑥The cutter bar cannot be lifted up and the burr cannot be scraped. ⑦ Internal burr scraping is periodic, scale-like and spiral-like. ⑧ Internal burr scraping deviation. ⑨ Other problems and solutions. According to these 9 kinds of common problems, we will explain to you the common problems of internal burr removal: internal burr ring knife collapse and internal burr residual height exceeding the standard.

Internal burr ring knife chipping:

The optimal working temperature of the inner burr ring knife is 650-900 ℃, but the inner burr ring knife collapses due to various reasons. The following are some common situations.

(1) Chipping of the over-strip joint. The welded joint of strip butt welding will have uneven deformation during forming, and it will collapse when it passes through the squeeze roll.

Solution:

①When the large-diameter pipe passes through the butt welding joint of strip steel, lower the cutter bar in time, and then raise the cutter bar after the butt welding joint of strip steel;

②Small-diameter pipes are less than 89mm, and the welded joints of strip steel must be ground flat to reduce chipping.

(2) The edge of the strip is bulging, and the edge of the strip is defective and chipped.

Solution:

①The bulge on the edge of the strip steel occurs when the wall of the production pipe is thin, and the forming machine is not adjusted properly, just adjust the forming machine to eliminate the bulge;

② It is enough to clear the inner burr of the defective part of the strip edge.

(3) It is easy to collapse when producing small diameter pipes below 76mm. Because the small diameter tube is filled with cooling water, rapid cooling of the weld can easily cause chipping.

Solution:

① Reasonable control of cooling water to avoid rapid cooling of welds;

②Add a blow pipe inside the welding area to isolate the cooling water from the welding area, increase the flow rate of the cooling water, increase the speed of the vehicle, etc. to reduce the chipping.

(4) When the car is just started, it is easy to break the knife because the knife is started too fast.

Solution:

Adjust the start-up time of the pressure reducing valve to be within 5s (that is, slow start-up), and the knife-drop time to be 2s (that is, fast-drop).

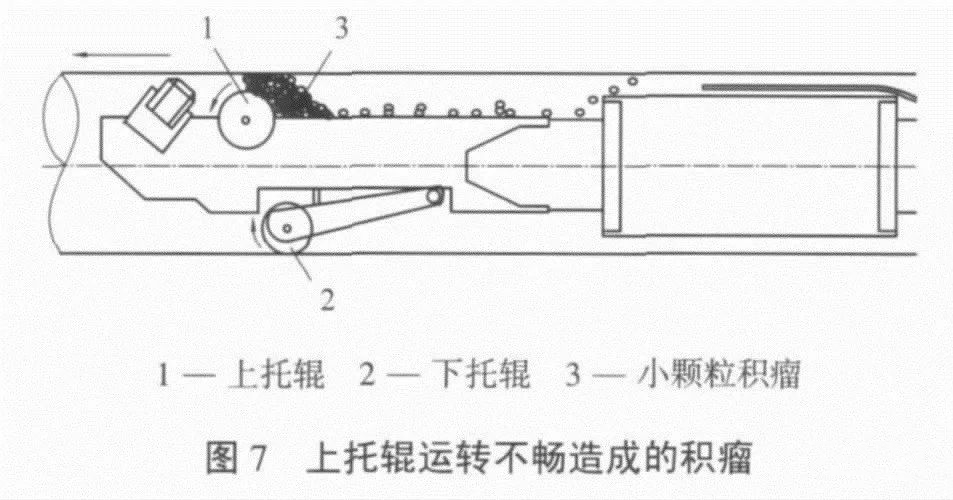

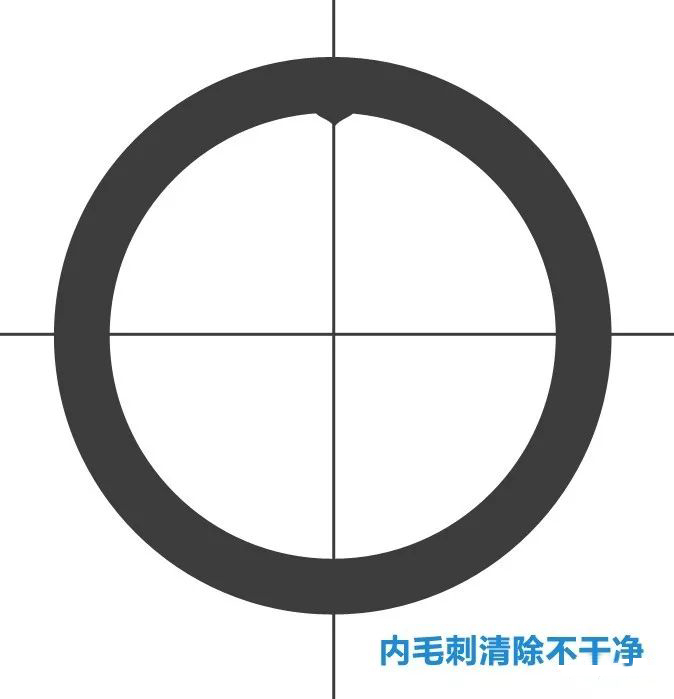

The residual height of the internal burr exceeds the standard: in the production of used roll forming equipment, after the internal burr of the small-diameter welded pipe is removed, there are likely to be residual marks in the steel pipe, as shown in the figure below. This kind of problem is often caused by the improper shaving of the burr knife or the improper adjustment of the burr knife.

Solution:

①The burr knife should be readjusted, and if the blade is worn, the knife should be re-sharpened. When using the oil cylinder to feed the knife, if the oil cylinder piston does not rise in place and the sealing ring is damaged, the high-quality fluororubber sealing ring should be replaced;

②If the oil quality is poor, the high temperature resistant oil should be replaced; check whether the oil pressure and the oil pump station are running normally.

Part of the content of this site comes from the Internet, this site only provides information storage, the copyright belongs to the original author, does not bear relevant legal responsibility, does not represent the views and positions of this site, if there is any infringement, please contact to delete.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province