Common problems and solutions for burr removal in high frequency welded pipe equipment (4)

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-03 11:30

- Pvs:

【概要描述】Internal burrs often appear when high frequency welded pipe equipment is used to make pipes, and there will also be many problems in removing internal burrs. We explain and deal with common problems in removing burrs from welded pipes.

Common problems and solutions for burr removal in high frequency welded pipe equipment (4)

【概要描述】Internal burrs often appear when high frequency welded pipe equipment is used to make pipes, and there will also be many problems in removing internal burrs. We explain and deal with common problems in removing burrs from welded pipes.

- Sort:Information

- Auth:

- Source:

- Release time:2022-04-03 11:30

- Pvs:

Internal burrs often appear when high frequency welded pipe equipment is used to make pipes, and there will also be many problems in removing internal burrs. We explain and deal with common problems in removing burrs from welded pipes.

There are 9 common problems in removing internal burrs with high frequency welded pipe equipment: ① The output power is too large. ②Welded weld bead. ③ The inner burr ring knife breaks down. ④ The residual height of the inner burr exceeds the standard. ⑤ The weld is in the shape of a peach. ⑥The cutter bar cannot be lifted up and the burr cannot be scraped. ⑦ Internal burr scraping is periodic, scale-like and spiral-like. ⑧ Internal burr scraping deviation. ⑨ Other problems and solutions. According to these 9 common problems, we will explain to you the common problems of internal burr removal: internal burr scraping and other problems and their solutions.

Internal burr scraping

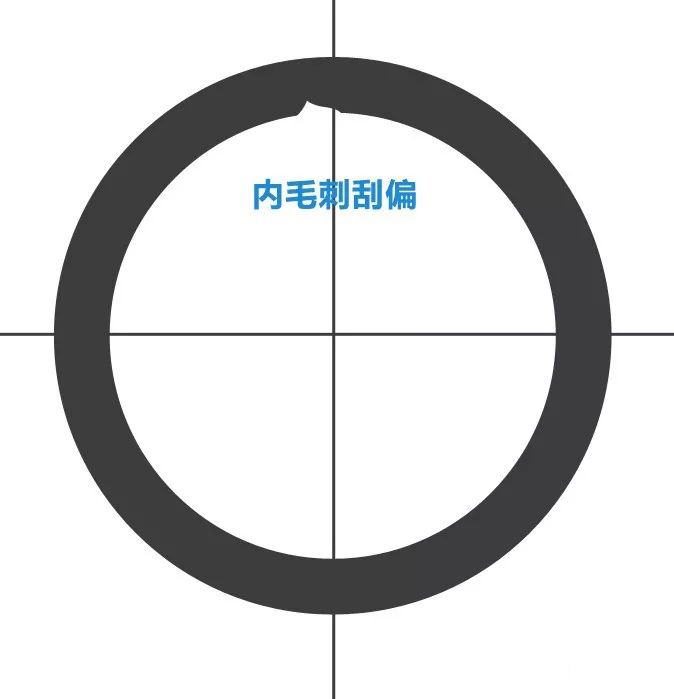

In the actual production process, the phenomenon of internal burr scraping (as shown in the figure below) is relatively common.

The main reasons for this problem are:

①Because the center position of the mandrel deviates from the welding seam, or the welding seam is uneven.

Solution: The position of the mandrel can be adjusted through the adjustment bolts of the connecting plate until the scraping phenomenon disappears;

②Because the working environment temperature of the mandrel rod is high and the cooling is poor, the mandrel rod deforms and causes scraping, so it is necessary to straighten the mandrel rod and deal with the cooling system of the mandrel rod until it meets the production requirements;

③Because the outer welding seam burr knife can be smoothed by the operator, but the welding seam is not flat on the left and right, resulting in the inner welding seam being just uneven.

Solution: According to the flatness of the inner welding seam of the pipe, adjust the welding squeezing roller to make the inner welding seam flat.

However, the phenomenon of intermittent offset on both sides of the internal burr scraping often occurs in production. There are two reasons for this:

(1)That the mandrel support wheel is not in good contact with the tube wall, which causes the mandrel to drive the cutter head to swing;

(2)That the lock nut of the mandrel connecting plate is loose, resulting in intermittent offset on both sides. It can be solved by adjusting the relative height of the cutter head and the support wheel; re-tighten the lock nut.

Other problems and handling

When producing a small-diameter welded pipe with a wall thickness of 1.5-3.5mm or less, the strip is a slit strip and the roll hole design is conventionally designed, so the positive and negative V-shaped butt welding is generated during welding, which will cause internal The size of the burr is uneven, and the scraping quality of the inner burr is not good.

Solution: Multi-radius should be used in the design of the roll hole shape, the 6th frame with guide plate is designed as a vertical ellipse, and the 7th and 8th frames are designed as flat ellipses. At the same time, in the production adjustment, when using two-roller extrusion, the upper rod of the extrusion roller can be tightened and the lower shaft rod can be adjusted loose, so that the inner burr is stable and even.

Deburring of small diameter HFW welded pipes is a key process in the production of high quality small diameter welded pipes. However, in the production process of high frequency welded pipe equipment, the use of the device and the removal of internal burrs often lead to slow welding speed, weld lumps, chipping, excessive residual height of internal burrs, scaly or spiral scraping of internal burrs, and scraping of internal burrs. Partial and other problems affect the quality and normal production of welded pipes. Therefore, no matter what the reasons are for these problems, targeted analysis should be carried out according to the specific problems, and corresponding solutions should be taken to produce high-quality small-diameter welded pipe products.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province