Common faults of used welded pipe mills production line forming machines (4)

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-19 11:30

- Pvs:

【概要描述】Common faults of used welded pipe mills production line forming machines can be divided into ① deviation. ② scratches. ③ "indenter" phenomenon. ④ "drill belt" phenomenon. In order to let everyone understand the common faults of the molding machine in detail, we will introduce ② scratches.

Common faults of used welded pipe mills production line forming machines (4)

【概要描述】Common faults of used welded pipe mills production line forming machines can be divided into ① deviation. ② scratches. ③ "indenter" phenomenon. ④ "drill belt" phenomenon. In order to let everyone understand the common faults of the molding machine in detail, we will introduce ② scratches.

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-19 11:30

- Pvs:

Common faults of used welded pipe mills production line forming machines can be divided into ① deviation. ② scratches. ③ "indenter" phenomenon. ④ "drill belt" phenomenon. In order to let everyone understand the common faults of the molding machine in detail, we will introduce ② scratches.

Scratches are generally easy to occur on the bottom and two sides of the pipe. The scratches on the bottom are mainly caused by the rounded corners of the lower edge R of the vertical roller pass, while the scratches on both sides are caused by the two edges R of the flat roll pass. Rounded corners cause more.

However, there are two reasons for the scratches of the forming machine of the used welded pipe mills production line, namely the scratches of the vertical rollers and the scratches of the flat rollers. We will introduce them in detail separately according to these two reasons.

2.2 Analysis of the causes of scratches on flat rollers

The scratch of the tube blank caused by the pass of the flat roll is closely related to the design of the pass.

(1) The shrinkage of the vertical roller is small

The main function of the vertical roll is to guide and assist the deformation of the tube blank during the rolling operation. There are certain requirements for the shrinkage of the vertical roll. If the shrinkage is insufficient, the edge of the flat roll pass will cause slight abrasion to the surface of the tube blank, especially the pass with the deformation center angle greater than 180°, the tube blank. The scratches on the surface are more obvious.

(2) Corner sharpening

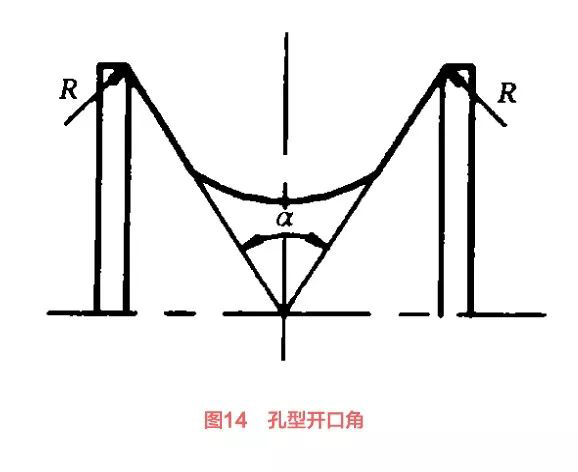

After the edge of the hole is sharpened, the surface of the tube blank is more likely to be scratched, especially for the opening hole with a deformed central angle greater than 180°. Therefore, after the R fillet is sharpened, the shrinkage of the vertical roller should be increased. When designing the hole pattern, it is necessary to increase the opening angle α and the edge fillet R of the hole pattern (Fig. 14).

(3) Flat roll cracking

Due to various reasons, the gap formed after the edge of the flat roll pass is cracked, which will leave periodic scratches on the surface of the tube blank during operation. The severity of this scratch is determined by the degree of cracking of the roll and the pressure of the upper roll. Therefore, after scratches occur, it is necessary to decide whether to change the rollers, or carry out grinding and adjustment according to the above actual conditions.

(4) The upper and lower rollers do not match

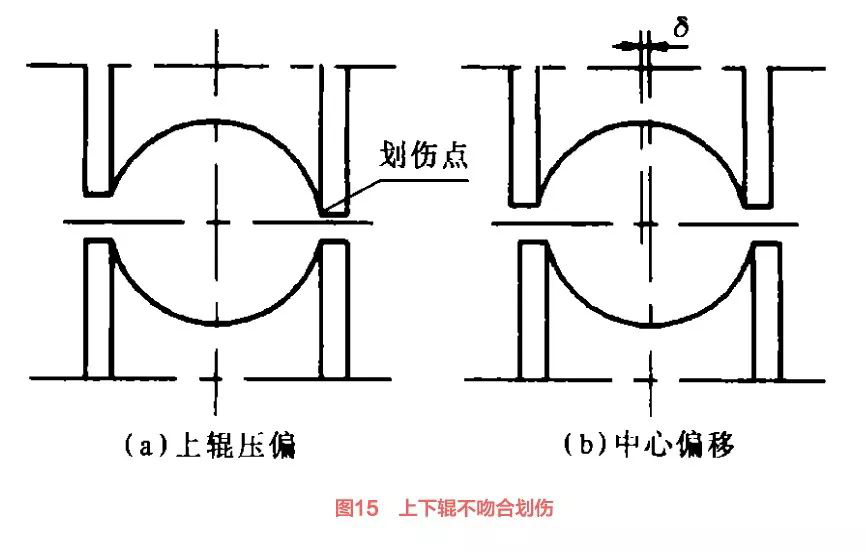

In the closed hole pattern, when the hole patterns of the upper and lower flat rollers do not match, it is easy to cause indentation scratches on both sides of the tube blank. There are two main reasons for the inconsistency:

One is the serious bias of the upper roller, as shown in Figure 15(a);

The second is that the center of a pass in the upper and lower roll passes has shifted, as shown in Figure 15(b).

Generally, after the center of the hole pattern is offset, the scratch is more serious. After finding out the cause according to the performance of the scratch, you can correct the hole type or adjust the pressure.

(5) Bearing damage

After the bearing of the lower roller is damaged, the center of the hole pattern is damaged. At this time, after the R fillet of the hole pattern is sharpened, it will cause a certain scratch on the surface of the tube blank. The higher the pressure on the upper roller, the more serious the scratch will be.

The reasons for the scratches in the common faults of the forming machines of the used welded pipe mills production line are mainly divided into vertical roller scratches and flat roller scratches. Today, we will introduce the cause analysis of flat roller scratches:①The shrinkage of the vertical roller is small. ②The corners are sharpened. ③The flat roller is cracked. ④ The upper and lower rollers do not match.⑤Bearing damage.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province