Common faults of used welded pipe mills production line forming machines (2)

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-13 11:30

- Pvs:

【概要描述】Common faults of used welded pipe mills production line forming machines can be divided into ① deviation ② scratches ③ "indenter" phenomenon ④ "drill belt" phenomenon. In order to let everyone understand the common faults of the molding machine in detail, we will introduce ① deviation.

Common faults of used welded pipe mills production line forming machines (2)

【概要描述】Common faults of used welded pipe mills production line forming machines can be divided into ① deviation ② scratches ③ "indenter" phenomenon ④ "drill belt" phenomenon. In order to let everyone understand the common faults of the molding machine in detail, we will introduce ① deviation.

- Sort:Information

- Auth:

- Source:

- Release time:2022-12-13 11:30

- Pvs:

Common faults of used welded pipe mills production line forming machines can be divided into ① deviation ② scratches ③ "indenter" phenomenon ④ "drill belt" phenomenon. In order to let everyone understand the common faults of the molding machine in detail, we will introduce ① deviation.

The deviation is also called turning over the belt. Due to various reasons, the deviation will occur at any time between the rolls of the forming machine. The specific performance is that after the tube blank comes out of the flat roll or vertical roll, the heights of the two edges are different. In severe cases, the tube blank will turn over and cannot enter the next pass smoothly, so it is forced to stop processing, which directly affects the production. Increase in work rate. However, there are two reasons for the deviation of the forming machine of the used welded pipe mills production line, that is, the deviation of the flat roll and the deviation of the vertical roll. We will introduce them in detail according to these two reasons.

1.2 Analysis of the causes of vertical roller deviation

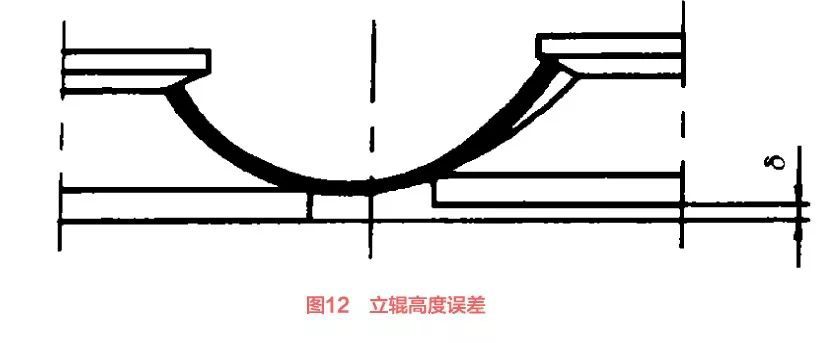

(1) The heights of the two vertical rollers are different. When the heights of the two vertical rollers are different, it is easy to cause the tube blank to turn over in the hole pattern. A slight height difference can be verified by detecting the upper boss of the vertical roll with a steel ruler, and in serious cases, it can be obtained by directly touching it with a finger.

(2)The bearing is damaged. When the vertical roller bearing is damaged, it is easy to cause the tube blank to deviate. After the bearing is damaged, the vertical roll pass cannot control the stable operation of the tube blank well, and also destroy the height position of the two vertical rolls. When the upper end bearing of the vertical roller is damaged, the tube blank will be turned up to the side of the hole pattern with the damaged bearing; when the lower end bearing of the vertical roller is damaged, the tube blank will be turned up to the side of the hole pattern with the intact bearing, and the bearing should also be considered. severity of damage.

(3) The front flat roller is not straight. At the flat roll before the vertical roll, the tube blank already has the phenomenon of deviation, which is mainly because the center of the flat roll is not correct. When the center deviation is small, the tube blank can barely enter the vertical roller hole, but if the vertical roller is slightly inappropriate in some aspects, and the center of the flat roll deviates greatly, the tube blank will be deviated and turned over. , so the flat roll pass must be adjusted to the center position. If the center of the flat roll is only slightly out of alignment, good results can also be obtained by adjusting the pressure of the flat roll.

(4) The size of the vertical rollers is different. When replacing the vertical rollers, it must be noted that the outer diameters of the two vertical rollers should be the same. At the center of the shape, the tube blank will shift to the side with the smaller roll diameter and turn up to the side with the larger roll diameter. In the production of thick-walled pipes with larger diameters, the phenomenon of deviation is not obvious, but when producing thin-walled tubes, deviations may occur. Moreover, the thinner the tube wall, the larger the error of the roll diameter, and the deviation The problem becomes more serious.

(5)The center of the vertical roller is not correct. When the deviation of the center position of the vertical roller is small, the deviation of the tube blank is not easy to occur, and the operation of the tube blank is relatively stable. Generally, the deviation of the flat roll can only be aggravated. Only when the center deviation is large, the deviation problem will be clearly exposed.

(6)The vertical roller moves axially. The slight axial movement of the vertical roller will generally not cause the tube blank to deviate, especially for ordinary thick-walled tubes. It is easy to occur only when producing small-diameter thin-walled tubes, because the rigidity of the tube blank is poor, and it is easy to be controlled by the swinging hole pattern and cause deviation. If the axial movement of the vertical roller is large, the probability of deviation will increase.

The reasons for the deviation of the common faults of the forming machine of the used welded pipe mills production line mainly include the deviation of the flat roll and the deviation of the vertical roll. Today, we will first introduce the analysis of the reasons for the deviation of the vertical roll: ① The heights of the two vertical rolls are different. ②The bearing is damaged. ③ The front flat roller is not correct. ④The size of vertical rollers is different. ⑤ The center of the vertical roller is not correct. ⑥The vertical roller moves axially.

More News

Time of issue : 2023-10-31

Time of issue : 2023-10-28

Time of issue : 2023-10-25

Time of issue : 2023-10-22

Wechat: 13392281699

Email: zty@usedpipemill.com

Company address:No. A99, East Lecong Avenue, Lecong Town, Foshan City, Guangdong Province

Recommendation

Online Inquiry

LINK

Contact Us

Tel (wechat): 13336487288

Wechat:+86 13336487288

WhatsApp:+86 13336487288

Email: zty@usedpipemill.com

Address: No. A99, Lecong Avenue East, Lecong Town, Foshan City, Guangdong Province